Patents

Literature

36results about How to "Avoid redevelopment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

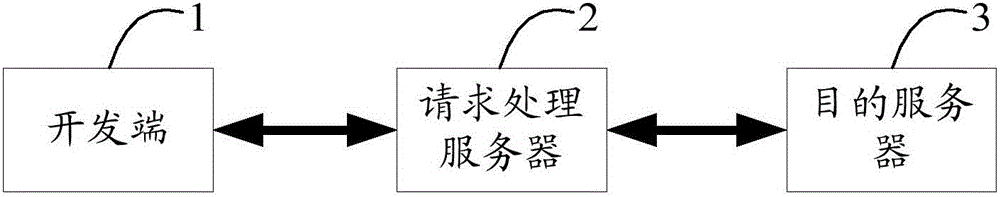

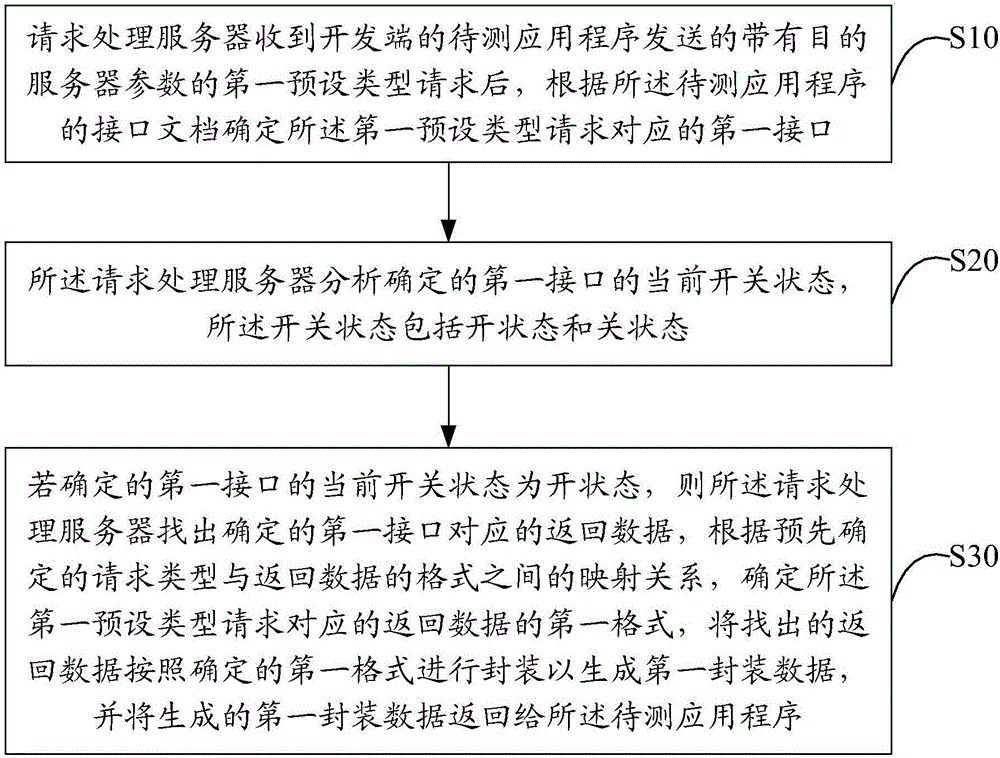

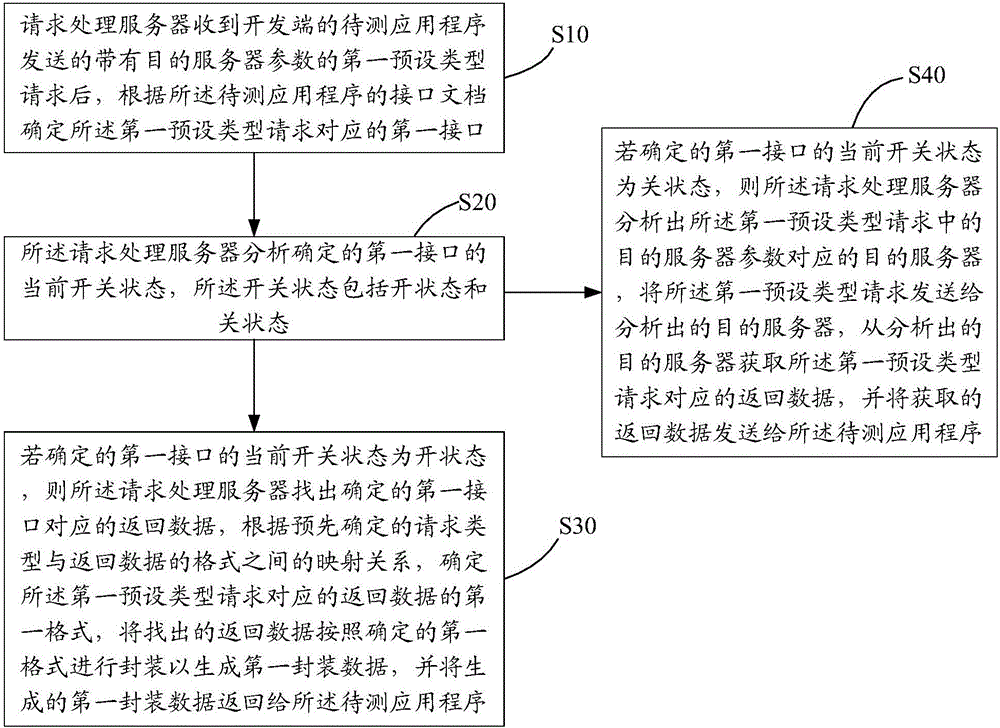

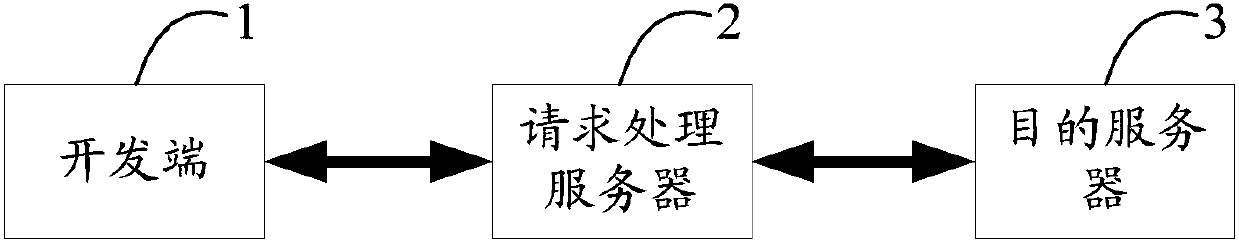

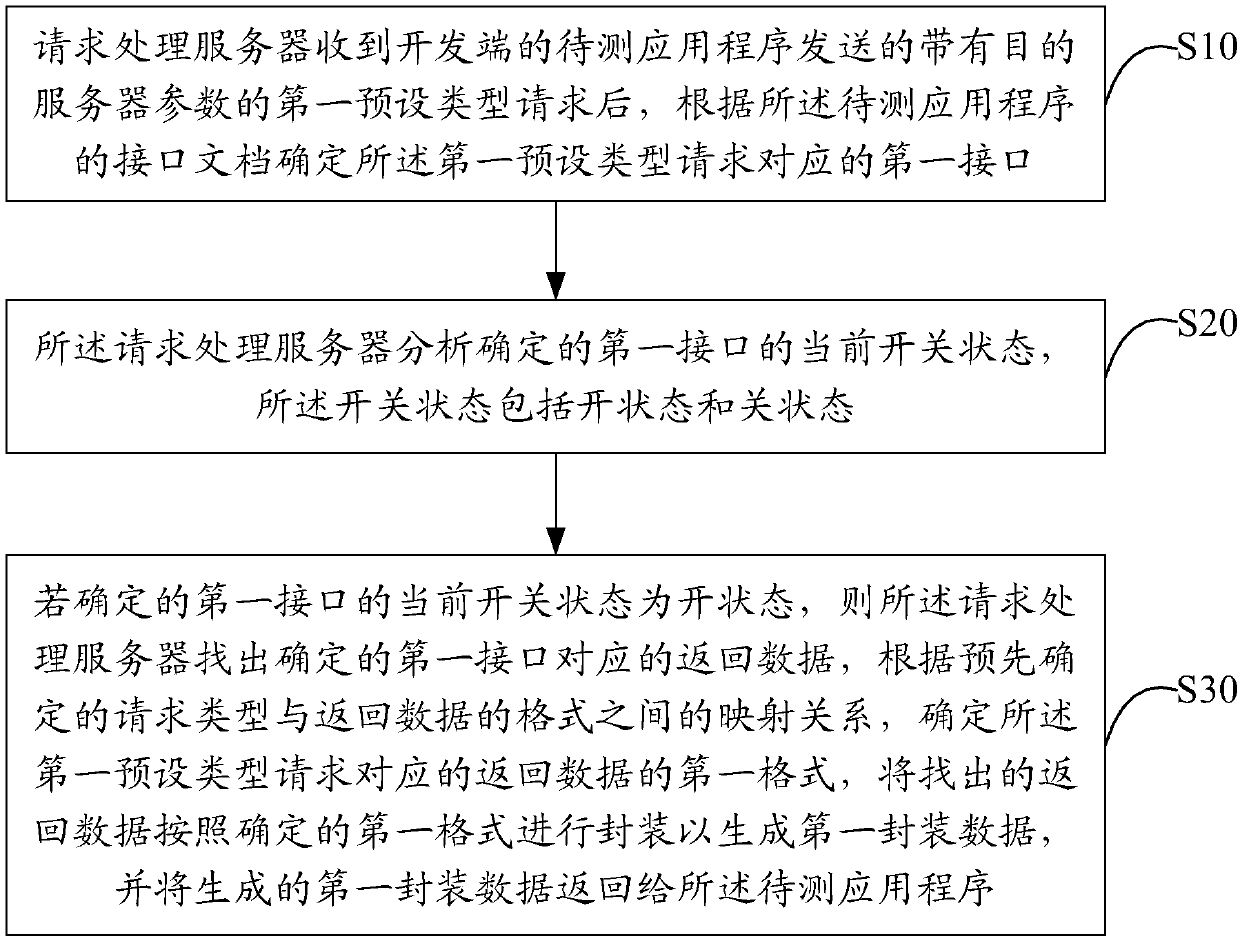

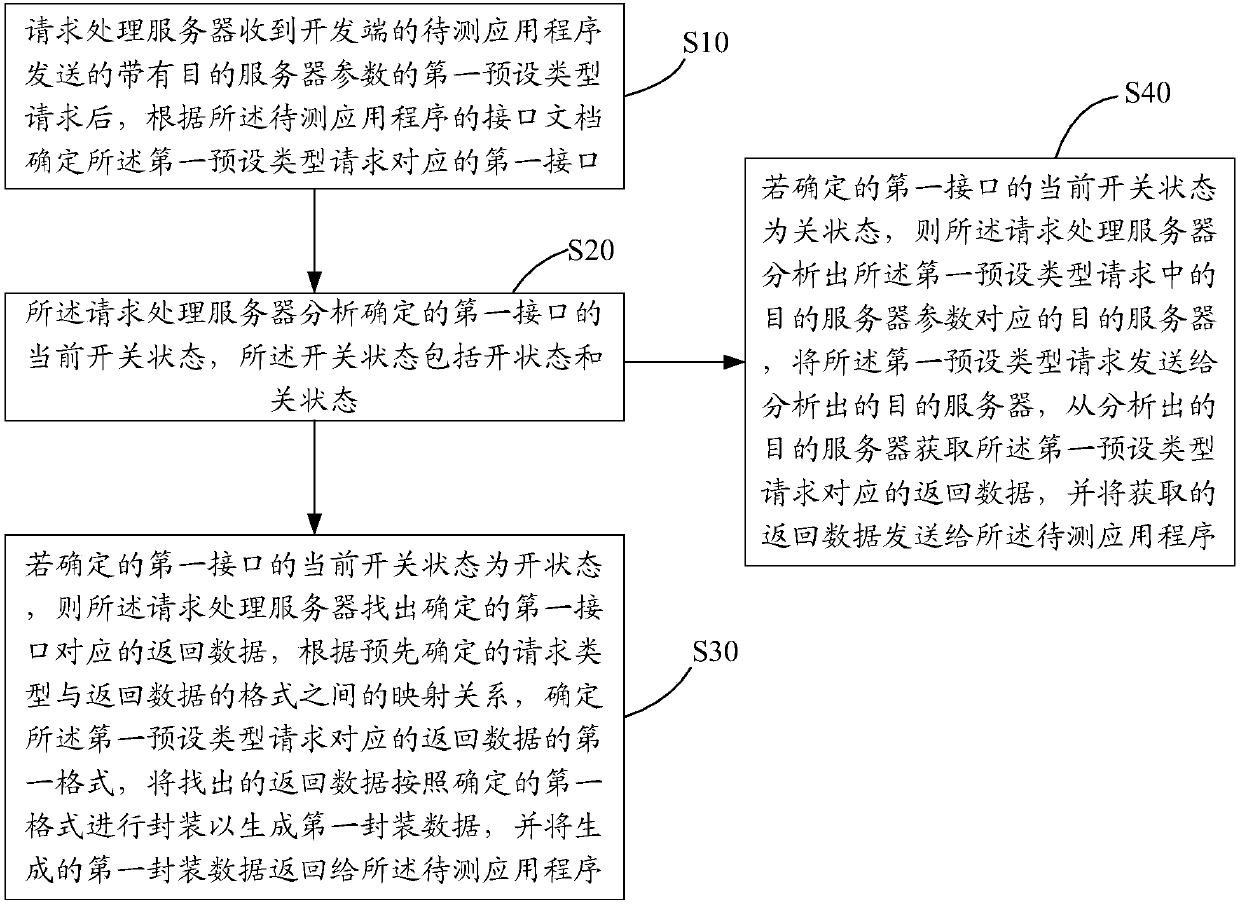

Simulation test method and server for use in application development process

ActiveCN106294179AImprove accuracyImprove efficiencySoftware testing/debuggingEncapsulated dataSoftware engineering

The invention discloses a simulation test method for use in an application development process, comprising: after a request processing server receives a first preset type request transmitted by an application to be tested in a development terminal, determining a first interface corresponding to the first preset type request according to an interface document of the application to be tested; analyzing current switch state of the first interface; if the current switch state is on state, finding return data corresponding to the first interface, determining a first format of the return data corresponding to the first preset type request according to a mapping relationship between a pre-determined request type and the format of the return data, packaging the return data according to the first format, and returning generated first packaged data to the application to be tested. The invention also discloses a request processing server for simulation test in an application development process. Development accuracy and efficiency of an application are effectively improved.

Owner:ONECONNECT TECH SERVICES CO LTD SHENZHEN

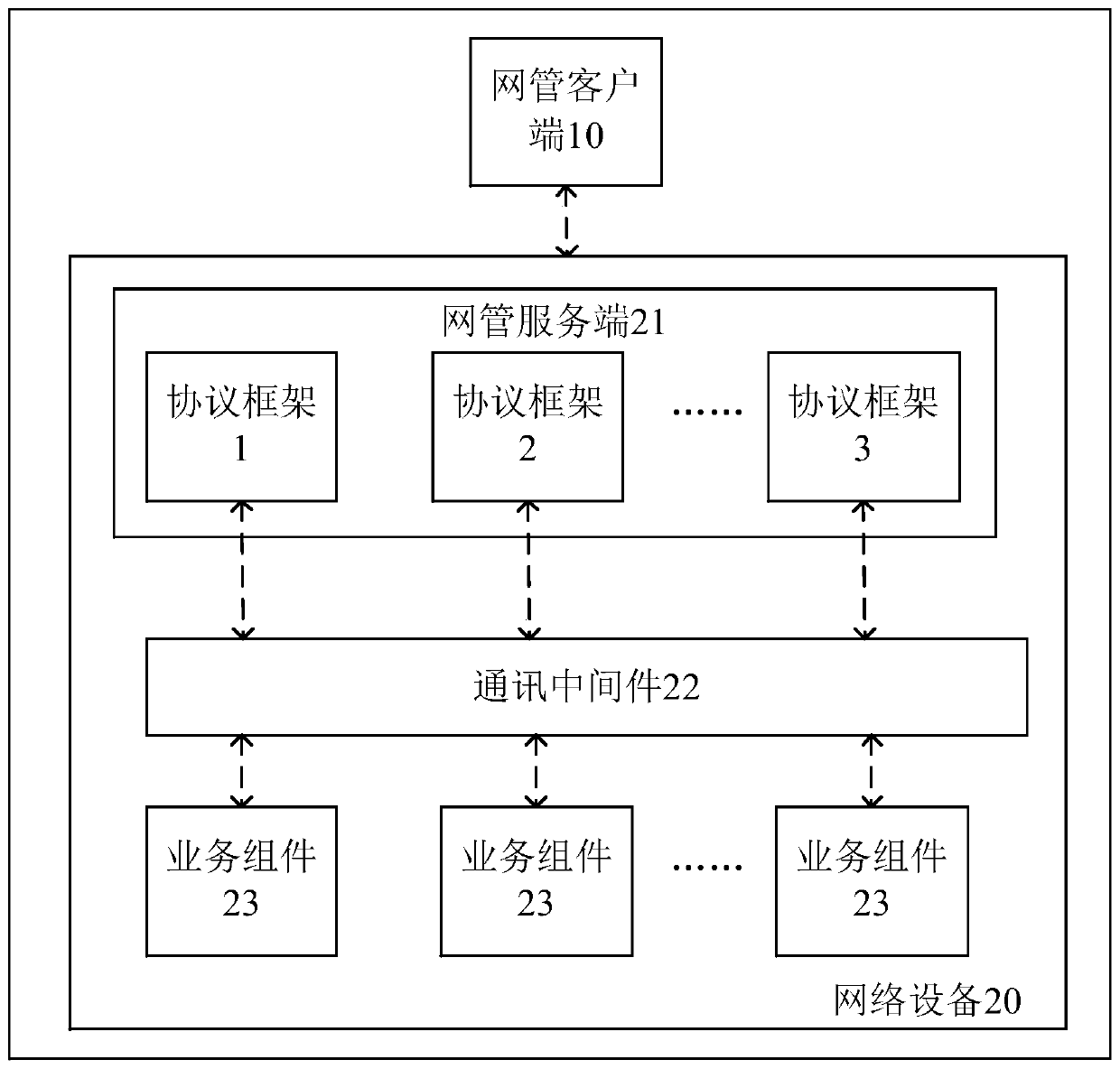

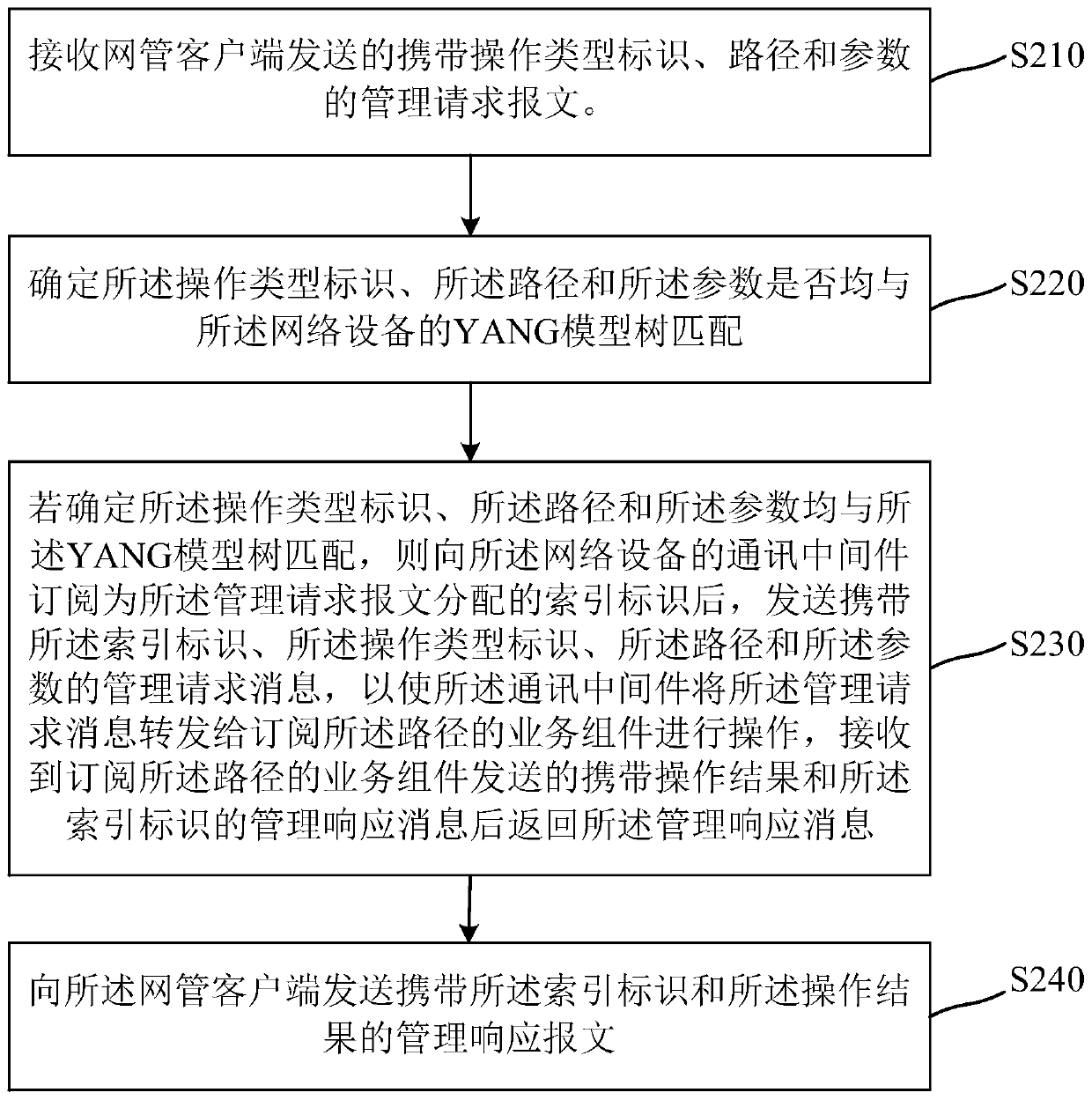

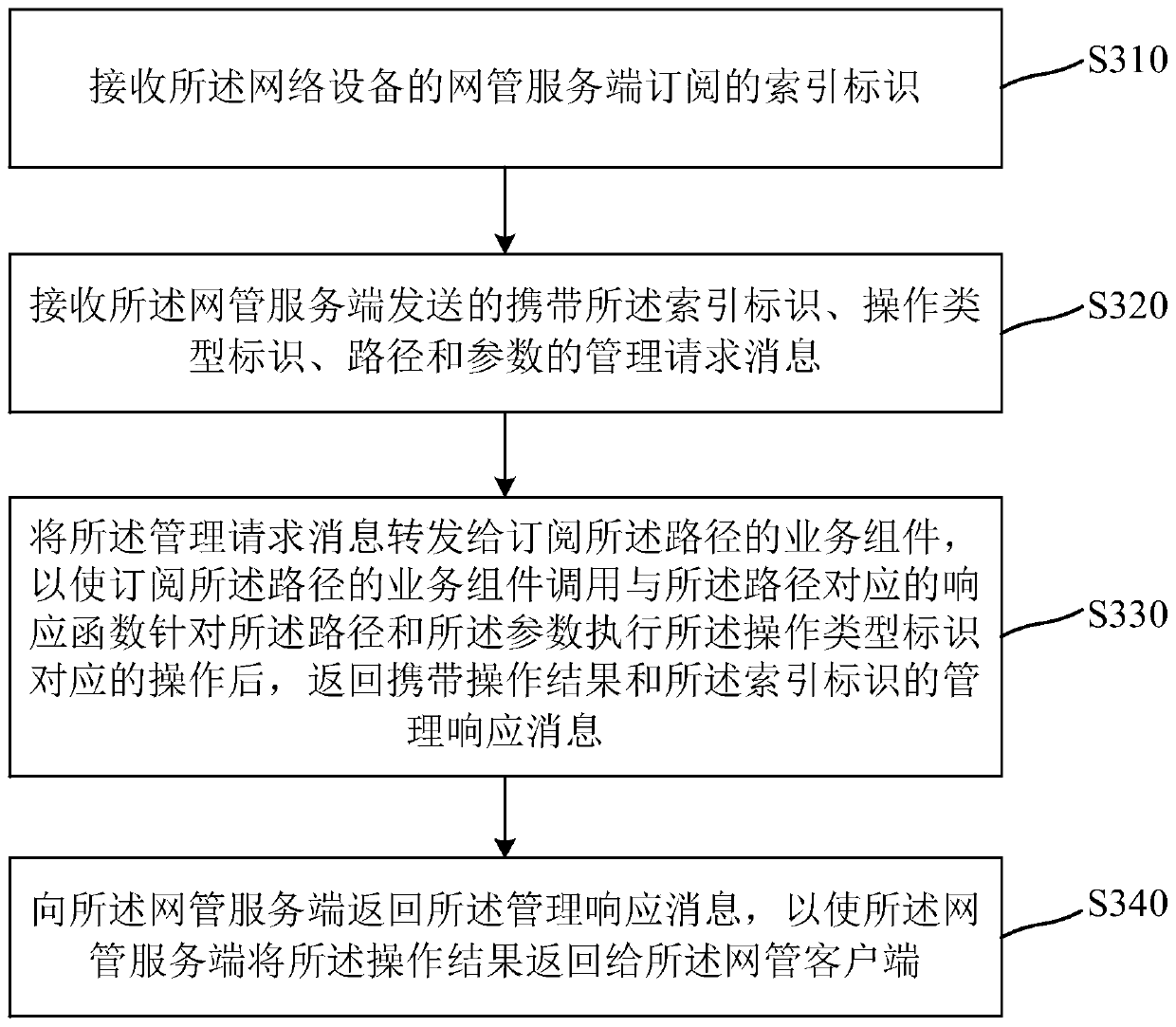

Network equipment configuration management method and device, computing equipment and storage medium

ActiveCN111416736ASafe and fast configuration managementAvoid redevelopmentInterprogram communicationData switching networksCommunication interfaceNetwork management

The invention discloses a network equipment configuration management method and device, computing equipment and a storage medium. A network management server can match information carried in a management request message from a network management client with a YANG model tree; after the matching is successful, a corresponding management request message is forwarded to each service component of thenetwork equipment through the communication middleware of the network equipment, so that the configuration, management and the like of the related service components can take effect, and the configuration management of the network equipment can be quickly and safely realized. According to the method and the device disclosed in the solution, the YANG model can be designed according to the configuration of the network equipment, the coupling of the communication interface of the service component and the user interface (UI) is prevented, and the development complexity is reduced; the development, operation and maintenance costs are reduced.

Owner:BEIJING XINWANG RUIJIE NETWORK TECH CO LTD

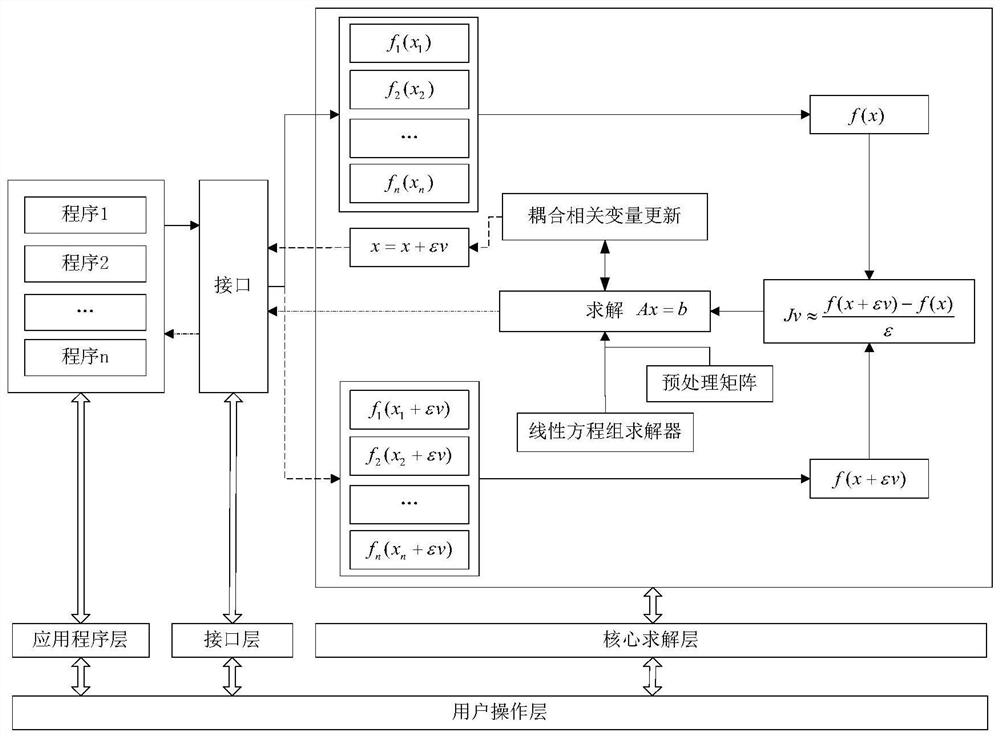

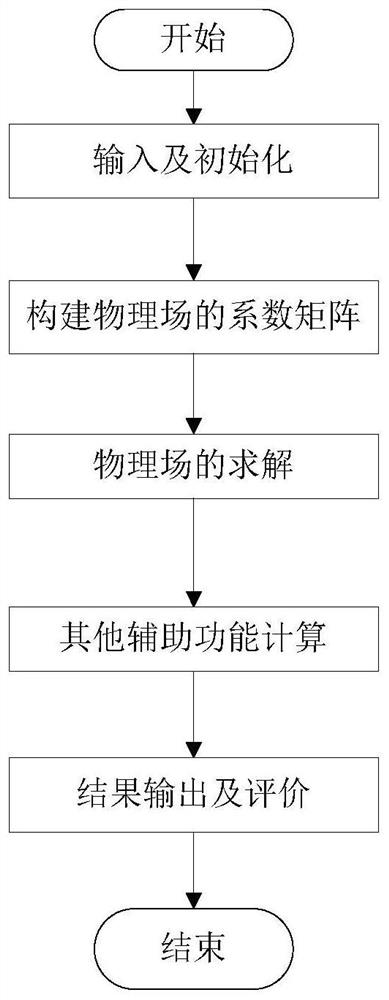

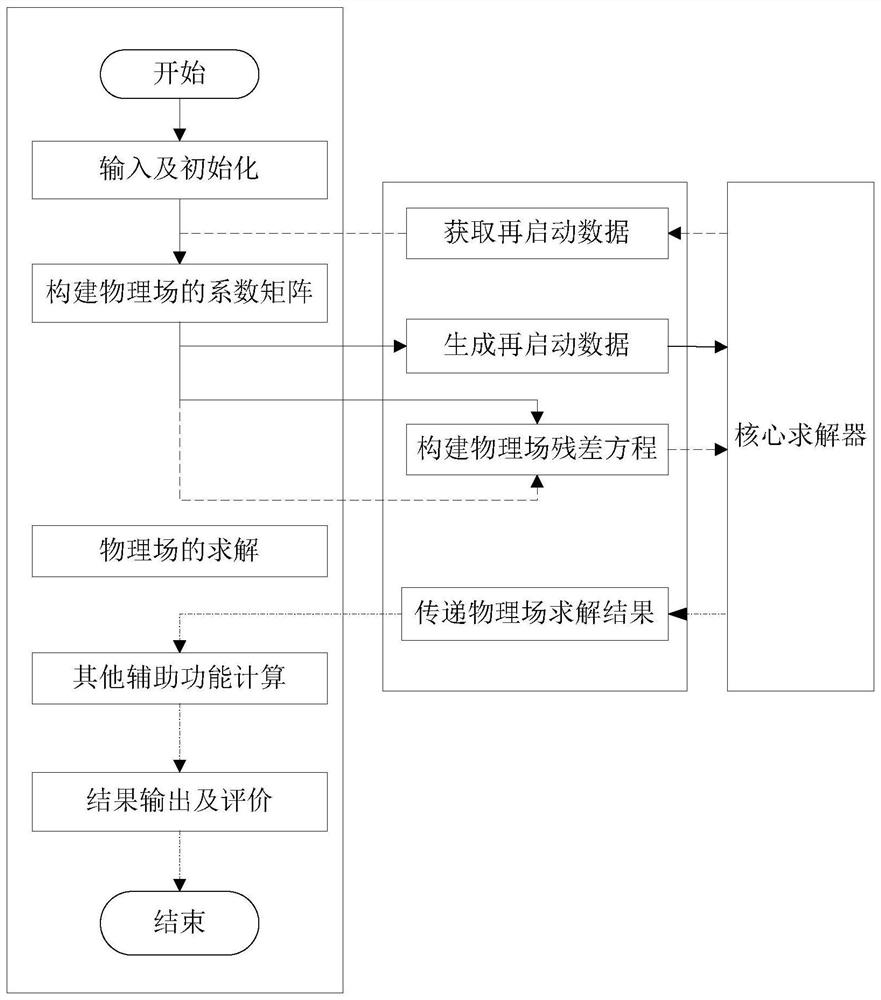

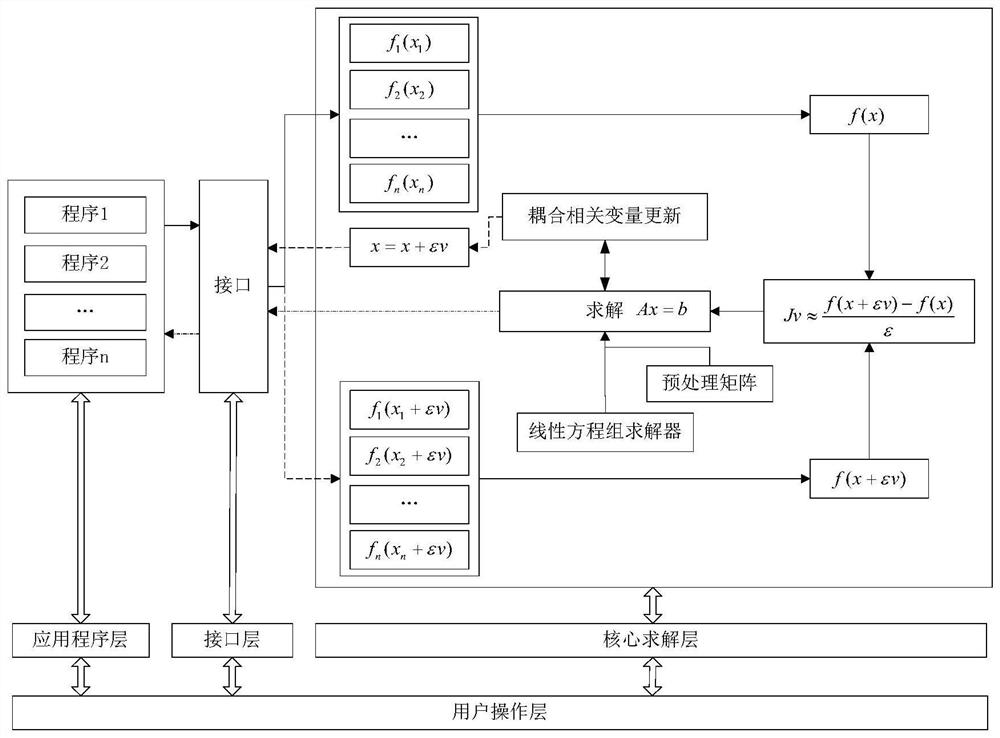

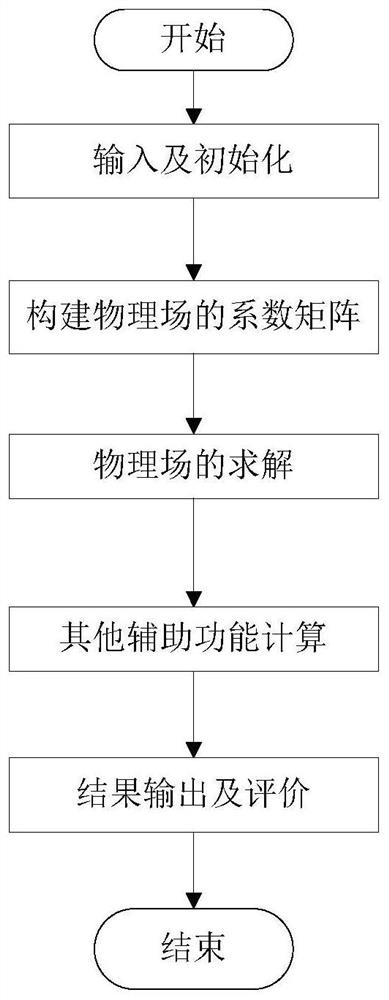

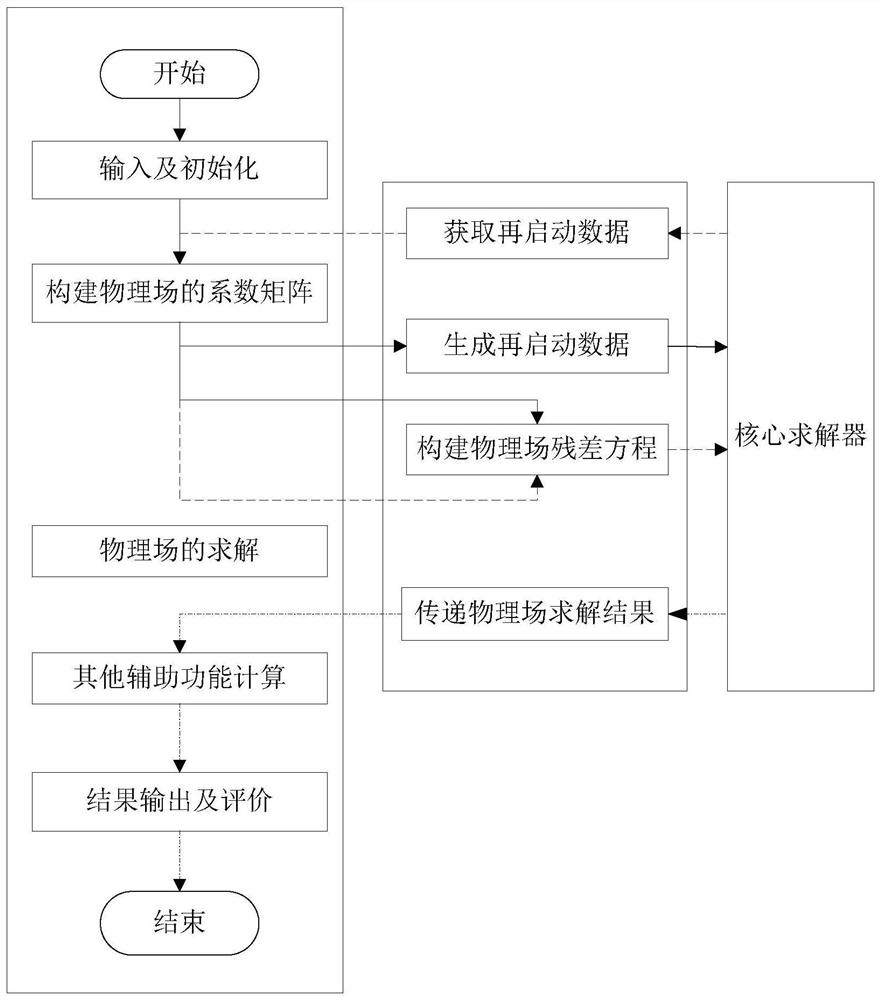

Reactor multi-physical field coupling calculation system and method

ActiveCN112364288APreserve the second-order convergence rateAvoid redevelopmentComplex mathematical operationsChemistryCalculated data

The invention discloses a reactor multi-physical-field coupling calculation system and method, relates to the field of nuclear reactors, and solves the problem that no mature multi-physical-field tight coupling calculation system exists. According to the invention, the system encapsulates and configures a plurality of calculation programs through an interface layer, and configures corresponding calculation programs through an application program layer according to reactor engineering calculation data types; wherein the interface layer is used for acquiring restart data, the restart data is reactor engineering calculation data imported by the interface layer, and the interface layer is used for constructing a physical field residual expression necessary for JFNK calculation based on an original physical field of the calculation data used for calculation of reactor engineering in the application program layer; transmitting the residual equation of the physical field to a core solving layer; and the interface layer is used for transmitting a physical field solving result between the core solving layer and the application program layer. The method can be used for program development, engineering design and accident analysis and evaluation of reactor engineering based on a multi-physical coupling concept.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

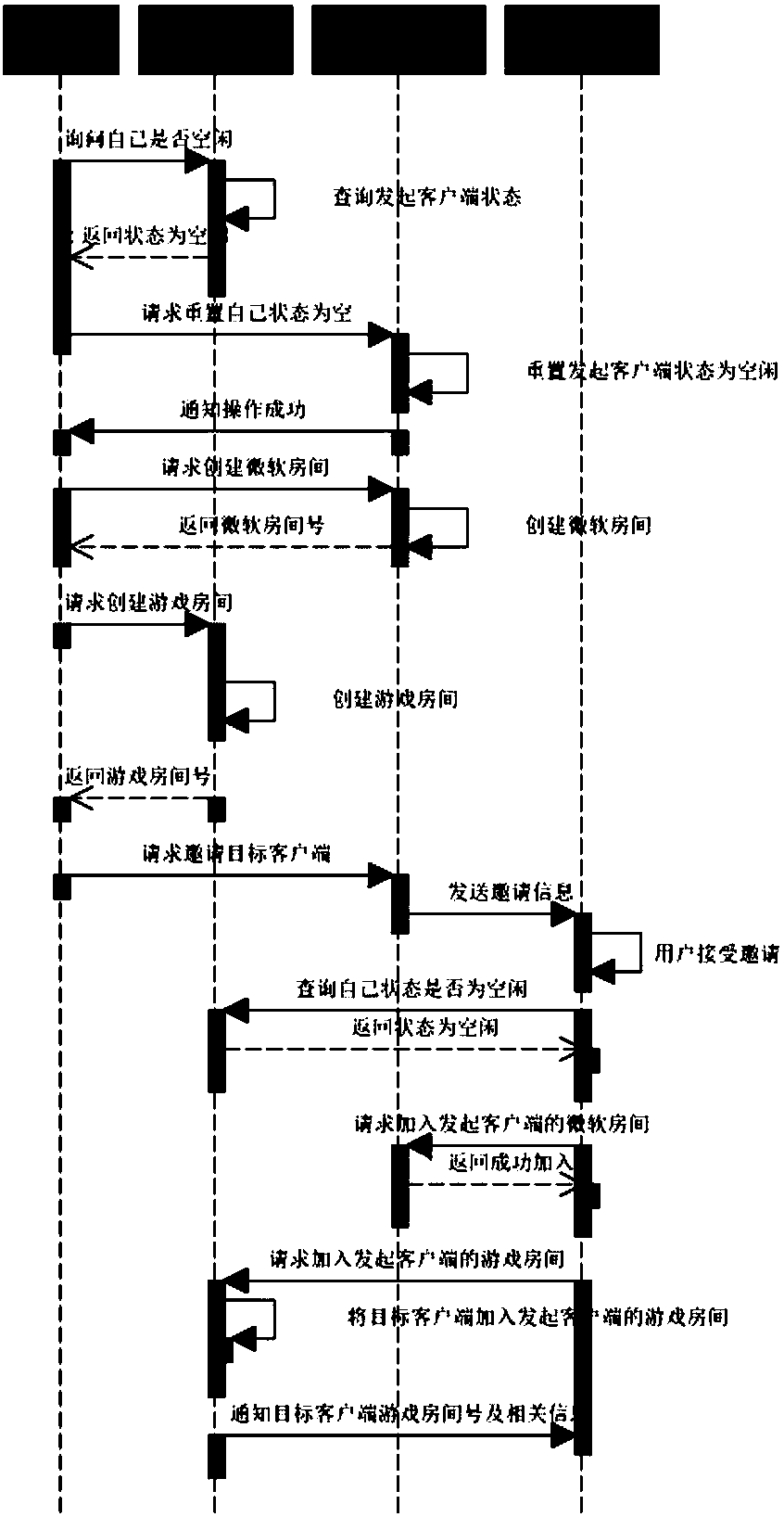

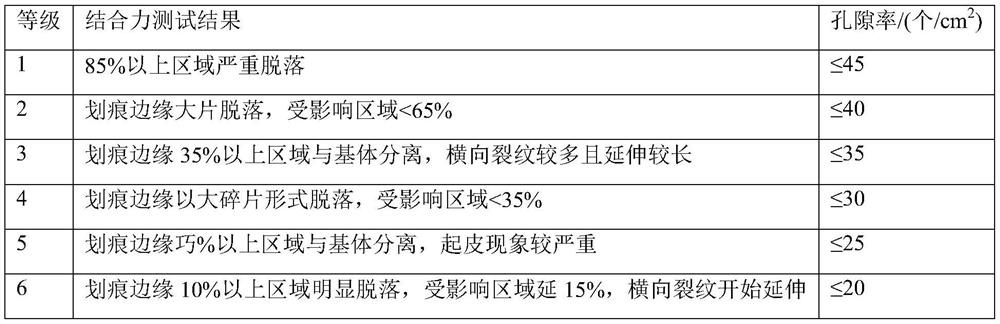

Xbox platform multiplayer game access control method based on client synchronization

ActiveCN107930113AAvoid disruptionComplies with mandatory requirementsVideo gamesMultiplayer gameGame server

The invention relates to an Xbox platform multiplayer game access control method based on client synchronization. A game outside invitation function of a multiplayer network war game on an Xbox seriesgame machine is implemented, the problem that player and room state data is not synchronized between a developer game server and an Xbox Live server, which leads to the interruption of original service processes is solved, and functions of 'game room' and 'Microsoft room' are integrated, and states are unified. The modification of a stable 'game room' function of a game server engine is avoided,and the disruption of original service processes by logic service developers for redevelopment is avoided. Multiplayer war network games on a traditional PC platform can be quickly transplanted to anXbox platform, so that game products conform to Microsoft mandatory requirements, and the products can be released on the line. The flexibility of an Xbox Live platform for the quick transplantation of the multiplayer war network games on the traditional PC platform is enhanced, the product development efficiency is improved, the development cycle is shortened, and the production labor cost is reduced.

Owner:SNAIL GAMES

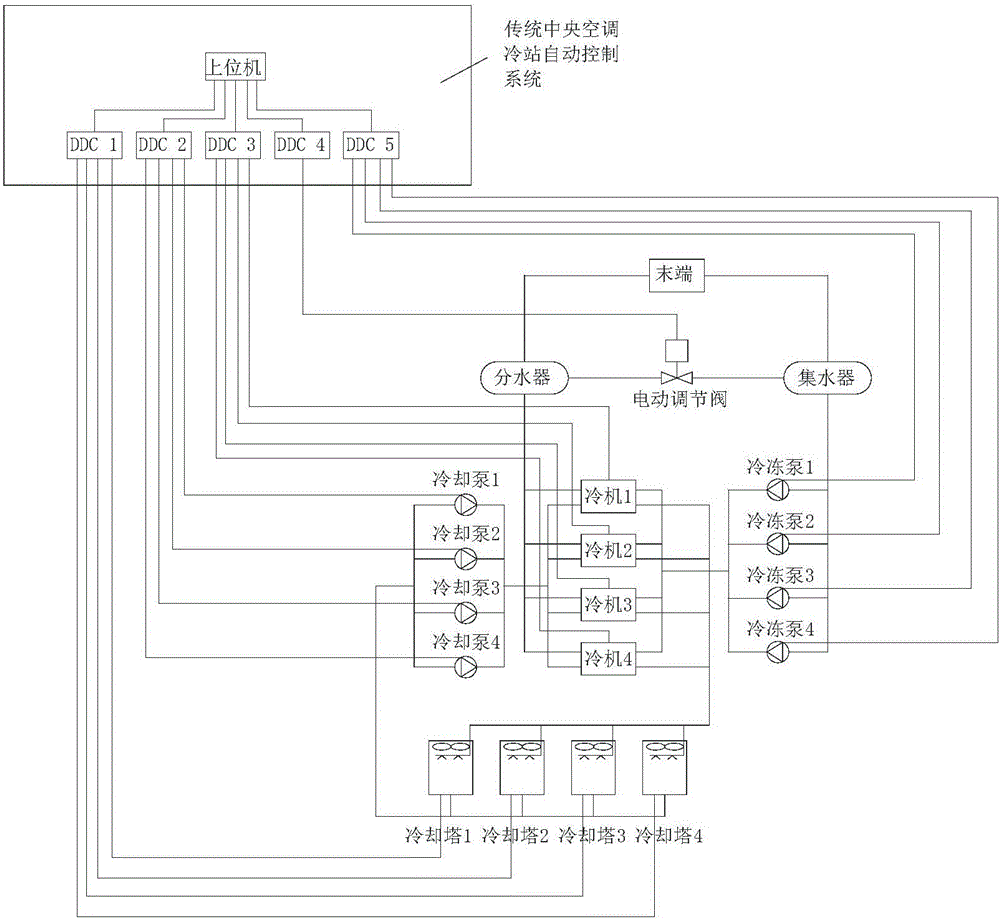

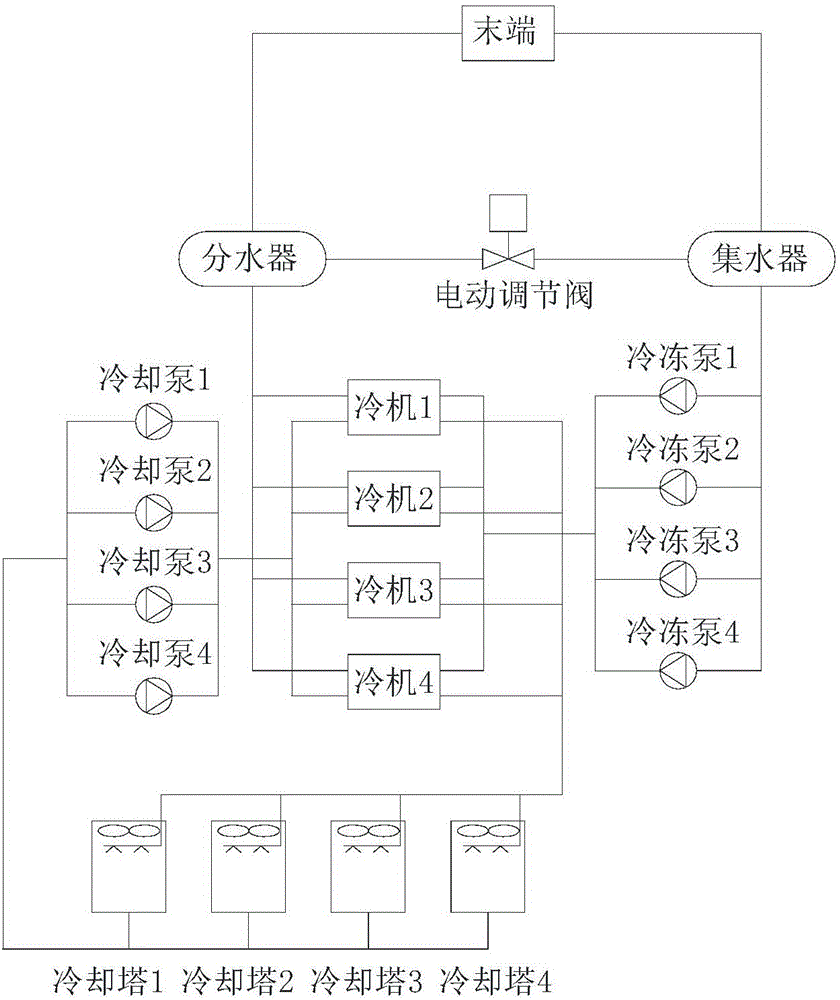

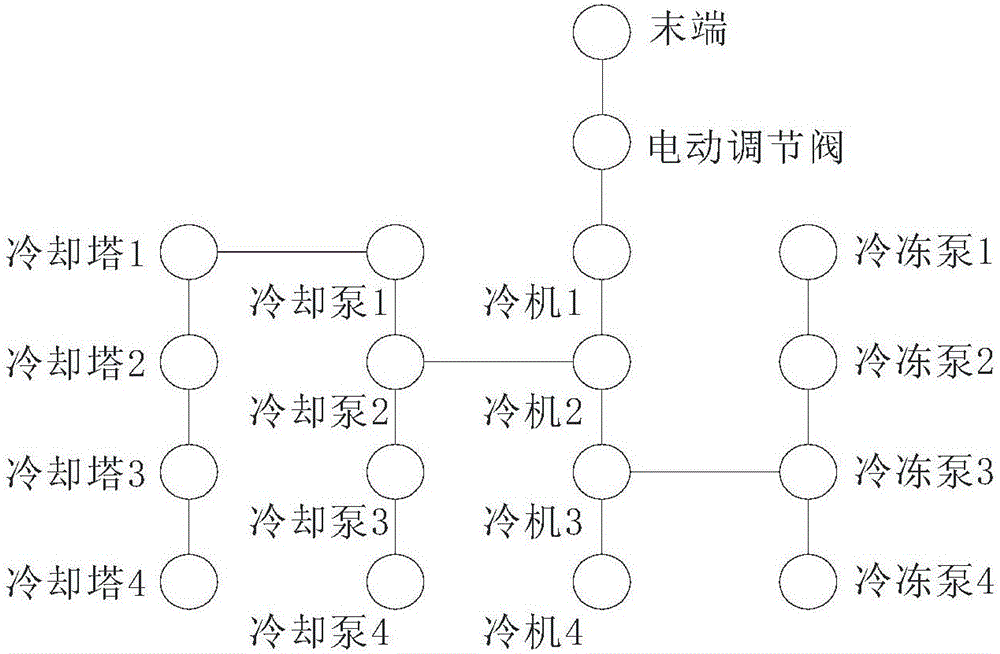

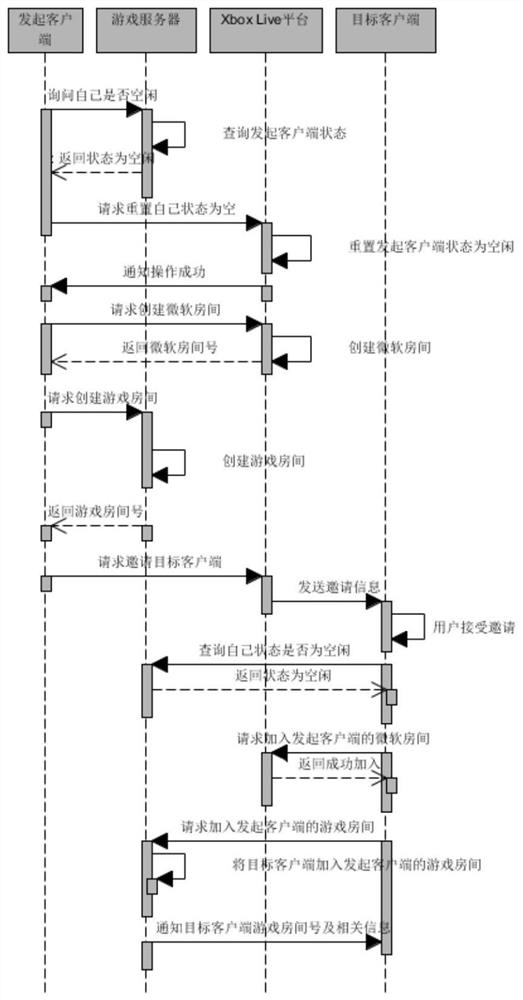

Control system for cold station of central air conditioner

InactiveCN106196512AReduce wiringReduce configuration workSpace heating and ventilation safety systemsLighting and heating apparatusControl systemWorkload

The invention discloses a control system for a cold station of a central air conditioner. The control system comprises a first cold station device set and a second cold station device set. The first cold station device set comprises one or more first cold station devices. Each first cold station device is connected with a first device controller. The first cold station devices in the first cold station device set are connected in parallel. The first device controller is used for adjusting the operating parameters of the connected first cold station devices. The second cold station device set comprises one or more second cold station devices. Each second cold station device is connected with a second device controller. The second cold station devices in the second cold station device set are connected in parallel. The second device controller is used for adjusting the operating parameters of the connected second cold station devices. The second device controller is in communication connection with the first device controller. The second cold station devices and the first cold station devices belong to different cold station devices. Through adoption of the control system, the technical problems of high control program development capacity and high workload of field connection and networking configuration and debugging in the control system for the cold station of the central air conditioner are solved.

Owner:GREE ELECTRIC APPLIANCES INC

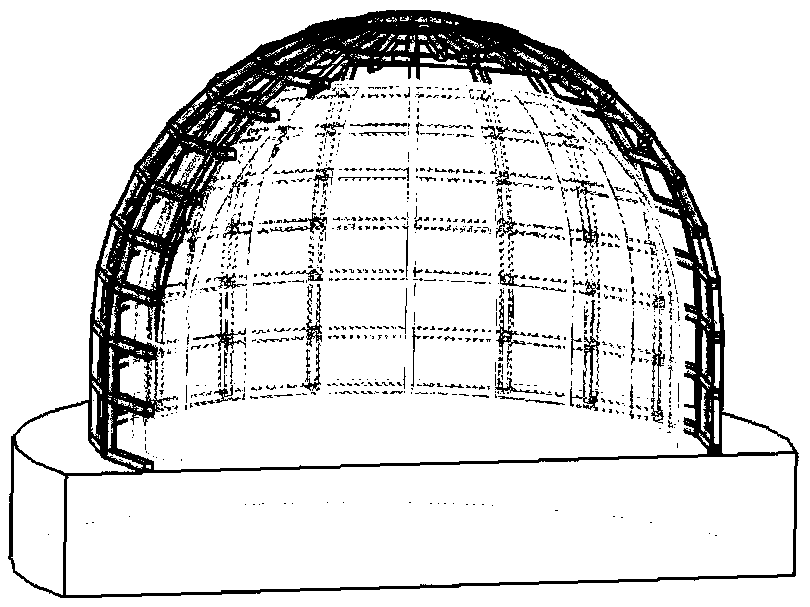

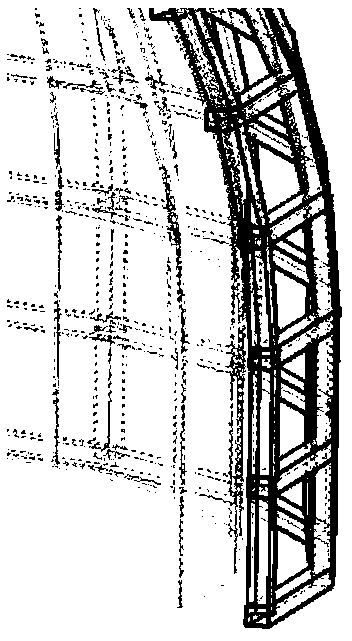

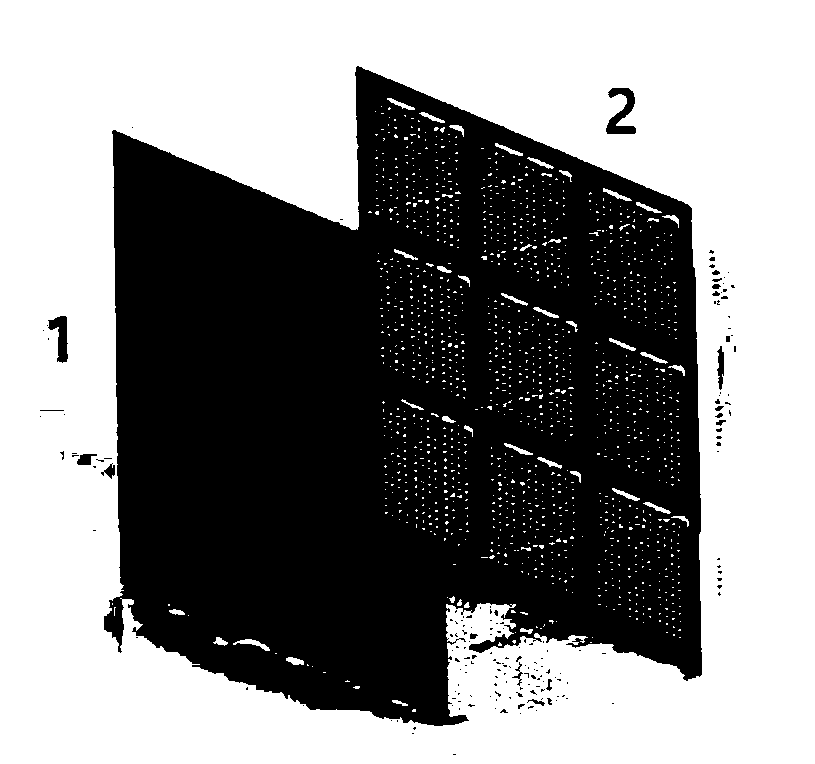

Light environment construction device

PendingCN109526108ABig spaceIncrease spaceElectrical apparatusElectroluminescent light sourcesNetwork controlModularity

A light environment construction device is mainly composed of three parts: diffusion plates, a light source and a control device. The main features are as follows: the diffusion plates are arranged onthe inner surface of a light environment, each diffusion plate is configured with a number of matching LED lamps on the back thereof, and the LED lamps are multi-color LED lamps with certain light distribution in order to achieve a modular function; the LED lamps have low-color-temperature and high-color-temperature lamp beads, and switching of the environment between color temperatures can be realized through mixed arrangement of the two kinds of lamp beads; and the device is controlled by a network control device for operating a power supply. The light environment construction device of theinvention is a modular optical device, and can realize the construction of a large-space, high-brightness, variable-color-temperature and modular light environment. Redevelopment due to different technical schemes is avoided, and the cost of secondary research and development is reduced.

Owner:上海昊瞻检测技术有限公司

Production technology for foaming car seat synthetic cotton

The invention discloses a production technology for foaming car seat synthetic cotton. The production technology comprises the following specific flows that raw materials including compound polyether and isocyanate are fed to a material pumping room, and a material pumping pump is used for pumping the compound polyether and the isocyanate into respective standby storage tanks; an automatic supplementing system is used for automatically feeding the compound polyether and the isocyanate of the standby storage tanks into a working storage tank to be mixed, and a high-pressure pouring machine pours the compound polyether and the isocyanate into a pouring gun head; a spraying gun is used for uniformly spraying a mould releasing agent to a mould cavity of a synthetic cotton mould; a fixing part in the car seat synthetic cotton is installed into a synthetic cotton mould locating block; after an upper mould body and a lower mould body of the synthetic cotton mould are combined, the pouring gun head pours mixed liquid into the synthetic cotton mould for foam forming; foamed synthetic cotton semi-finished products are placed into a sealing space of a cell crushing machine, and internal cells of the synthetic cotton semi-finished products are subject to vacuum extrusion to be discharged out; and the synthetic cotton semi-finished products obtained after the cells are crushed are repaired, checked and put in storage finally. The process technology is simple, saves the production cost and is high in production efficiency.

Owner:陈忠杰

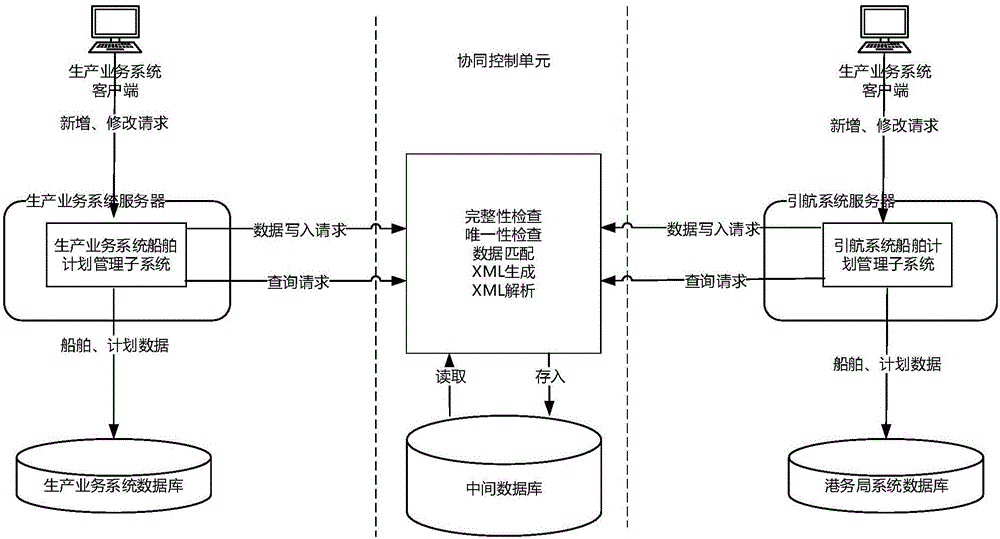

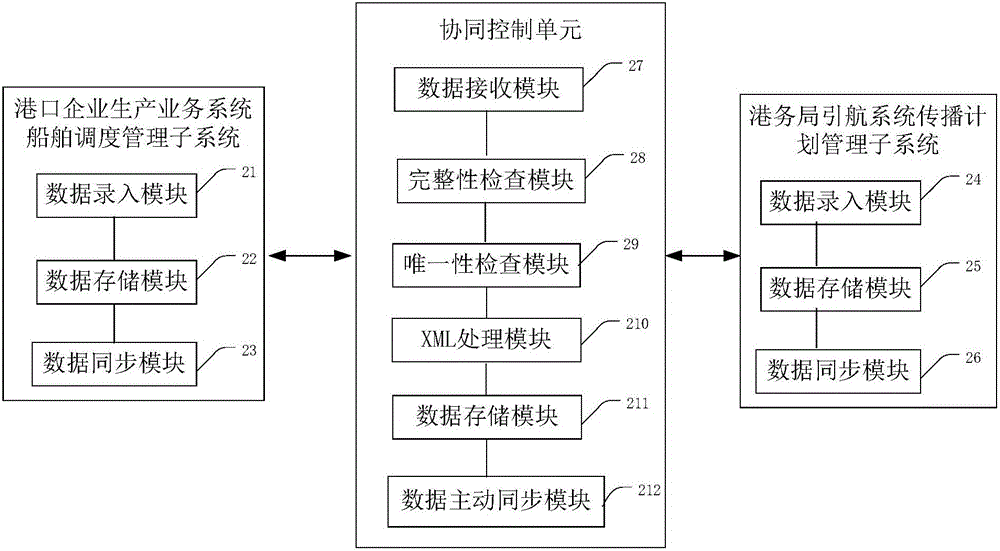

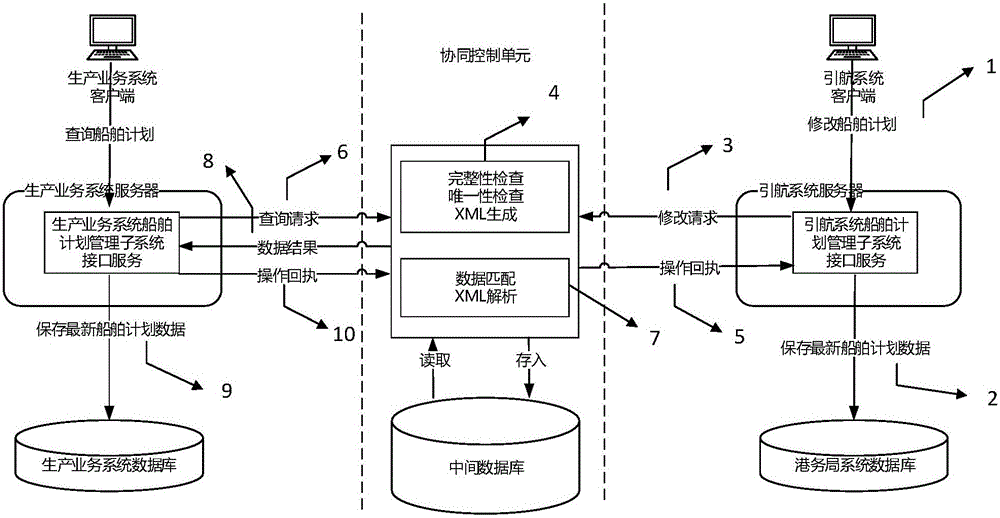

Port enterprise and port office coordinately developed ship dispatching method and system

The invention provides a port enterprise and port office coordinately developed ship dispatching method and system. The system comprises a port enterprise production business system ship dispatching management subsystem, a port office piloting system ship planning management subsystem and a coordinate control unit, wherein the port enterprise production business system ship dispatching management subsystem and the port office piloting system ship planning management subsystem are used for managing basic information of ships and ship dispatching / operation plans; and the coordinate control unit is used for storing and updating the ship dispatching / operation plans through an intermediate database, and carrying out ship dispatching / operation plan synchronization with the port enterprise production business system ship dispatching management subsystem and the port office piloting system ship planning management subsystem. The port enterprise and port office coordinately developed ship dispatching method and system can be used for solving the problem of data exchange between existing production business systems of the port enterprises and a piloting system of the port office, so that the port enterprises are prevented from researching and developing the production business systems again, and the work coordination abilities of the port enterprises and the port office are improved.

Owner:BEIJING JIAOTONG UNIV

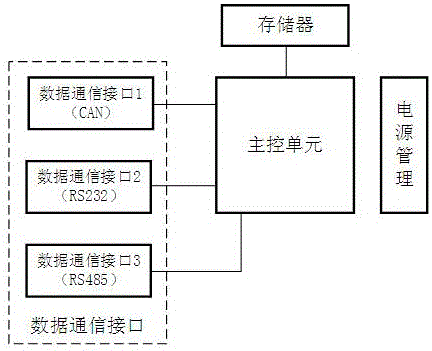

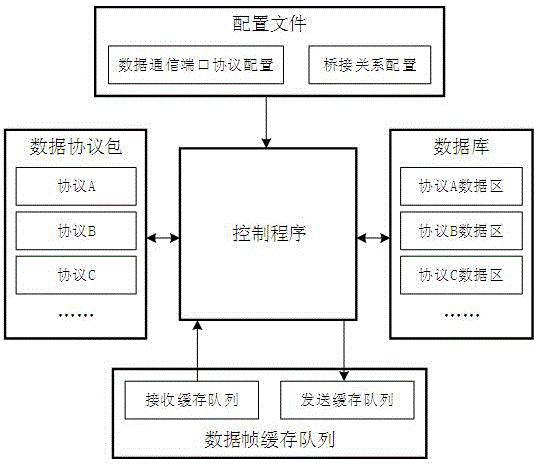

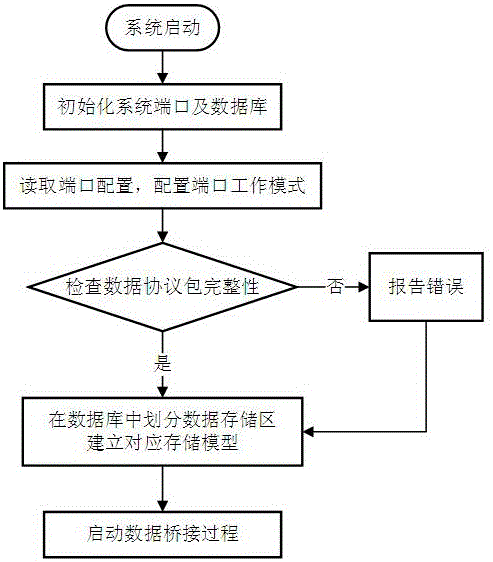

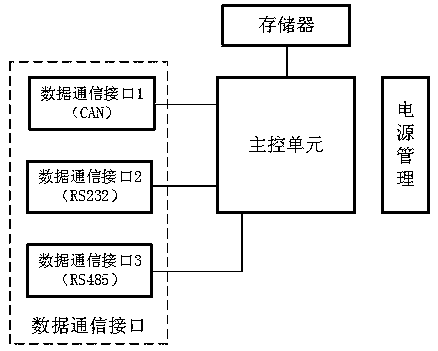

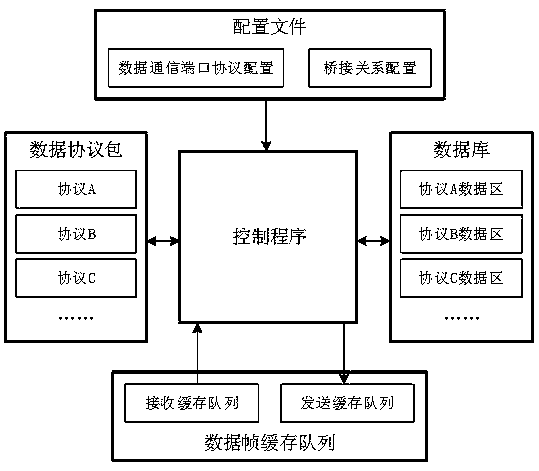

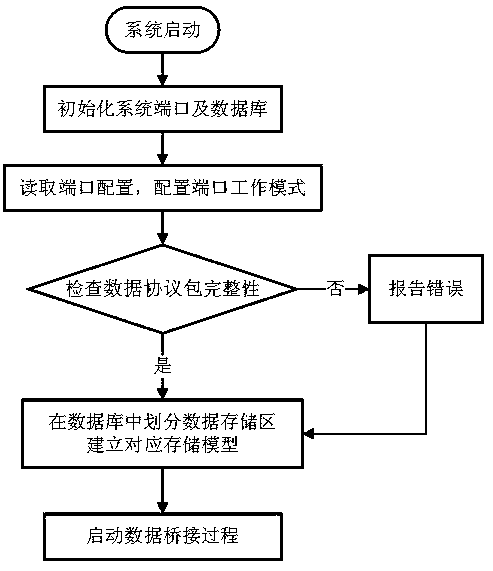

Configurable multiport general data bridging system and working method thereof

ActiveCN106598885AReduce communication costsAvoid redevelopmentElectric digital data processingData functionStorage cell

The invention belongs to the field of communication technology and provides a configurable multiport general data bridging system and a working method thereof. The system comprises a hardware part and a software part for achieving a specific function; the hardware part comprises a plurality of data communication ports, a storage unit and a main control unit, wherein the data communication ports have data transmitting and receiving functions and are used for receiving and transmitting data frames; the storage unit is used for storing needed data and files; the main control unit is used for running the software part and coordinating running of the data communication ports and the storage unit to complete the data bridging process; the software part comprises a configuration file, a data frame cache queue, a data protocol package, a control program and a database. Different data systems can be bridged, and a data bridging scheme which is lower in cost and more convenient to use is provided.

Owner:HUAZHONG UNIV OF SCI & TECH

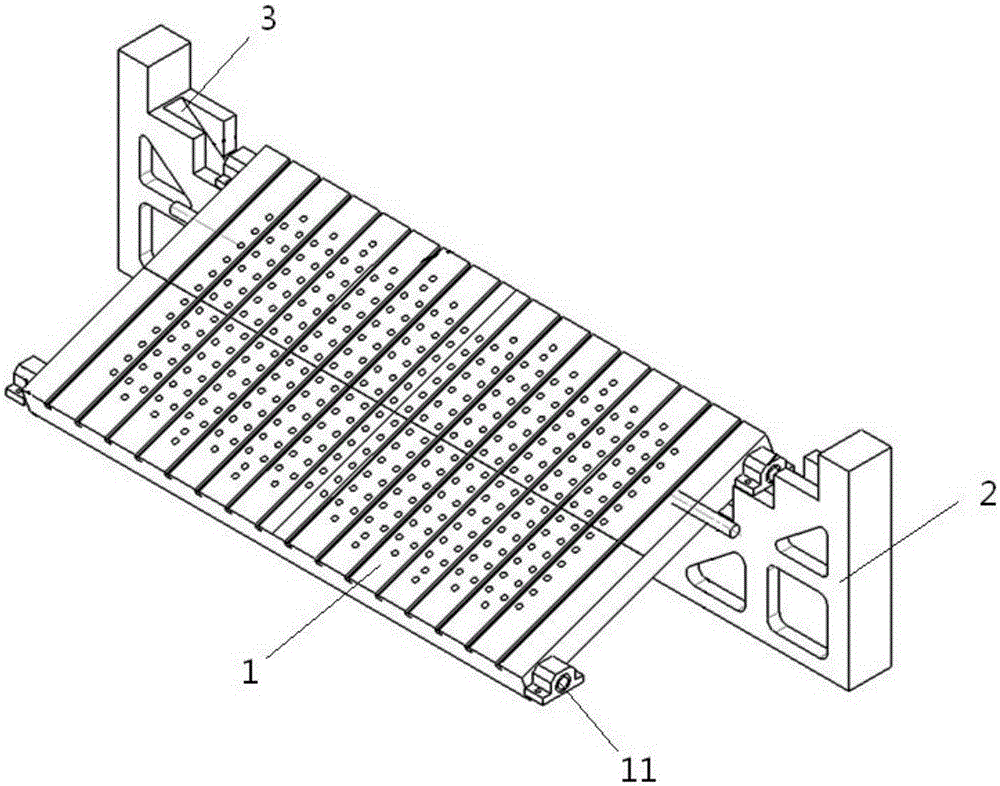

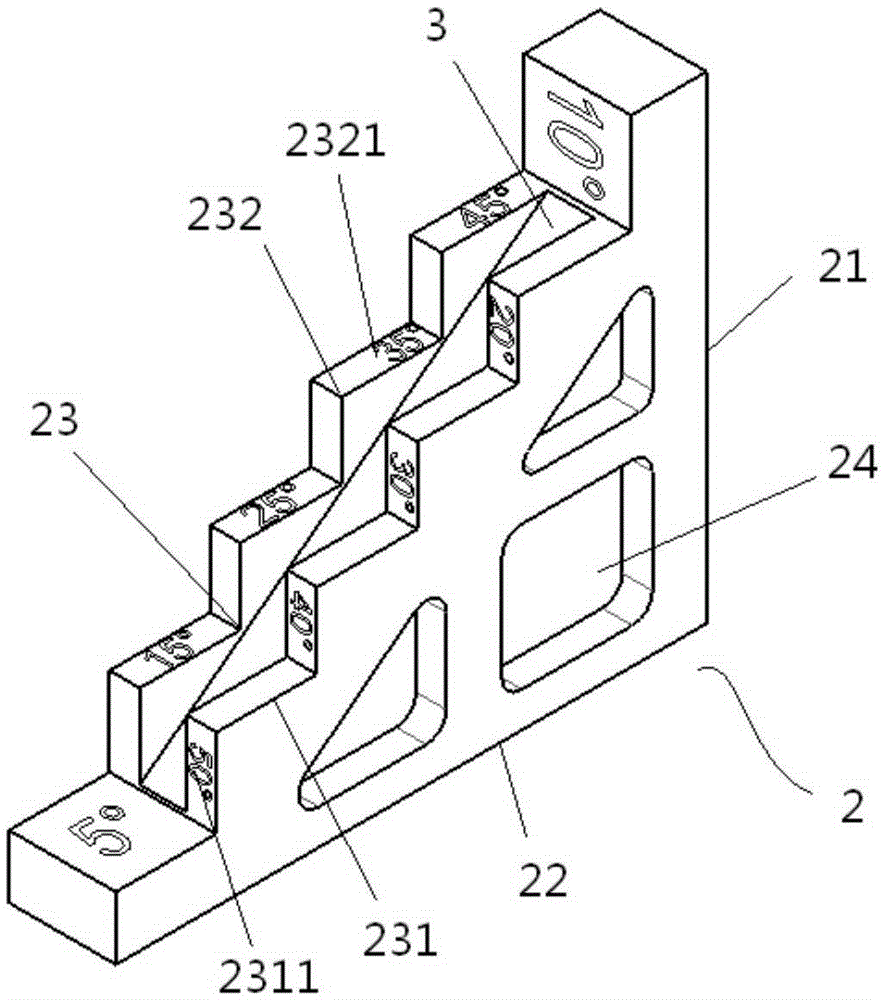

Adjustable inclined wedge fixing base

InactiveCN105290818AAvoid redevelopmentShorten development timePositioning apparatusMetal-working holdersEngineering

The invention discloses an adjustable inclined wedge fixing base. The adjustable inclined wedge fixing base comprises an inclined wedge fixing plate and further comprises an adjusting base. The adjusting base comprises a first edge, a second edge and a third edge; the first edge is perpendicular to the second edge; the third edge is connected with the first edge and the second edge; the third edge comprises a first lap joint plate and a second lap joint plate which are arranged in parallel; a plurality of first lap joint parts are arranged on the first lap joint plate side by side; a plurality of second lap joint parts are arranged on the second lap joint plate side by side; the first lap joint parts and the first edge are arranged in parallel; the second lap joint parts and the second edge are arranged in parallel; one end of the inclined wedge fixing plate is provided with a rotating connection part; and the other end of the inclined wedge fixing plate is in lap joint with the first lap joint parts or the second lap joint parts. According to the adjustable inclined wedge fixing base, an inclined wedge has universality at different inclination angles, it is avoided that the inclined wedge needs to be re-developed at each angle, and the mold development time is shortened.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

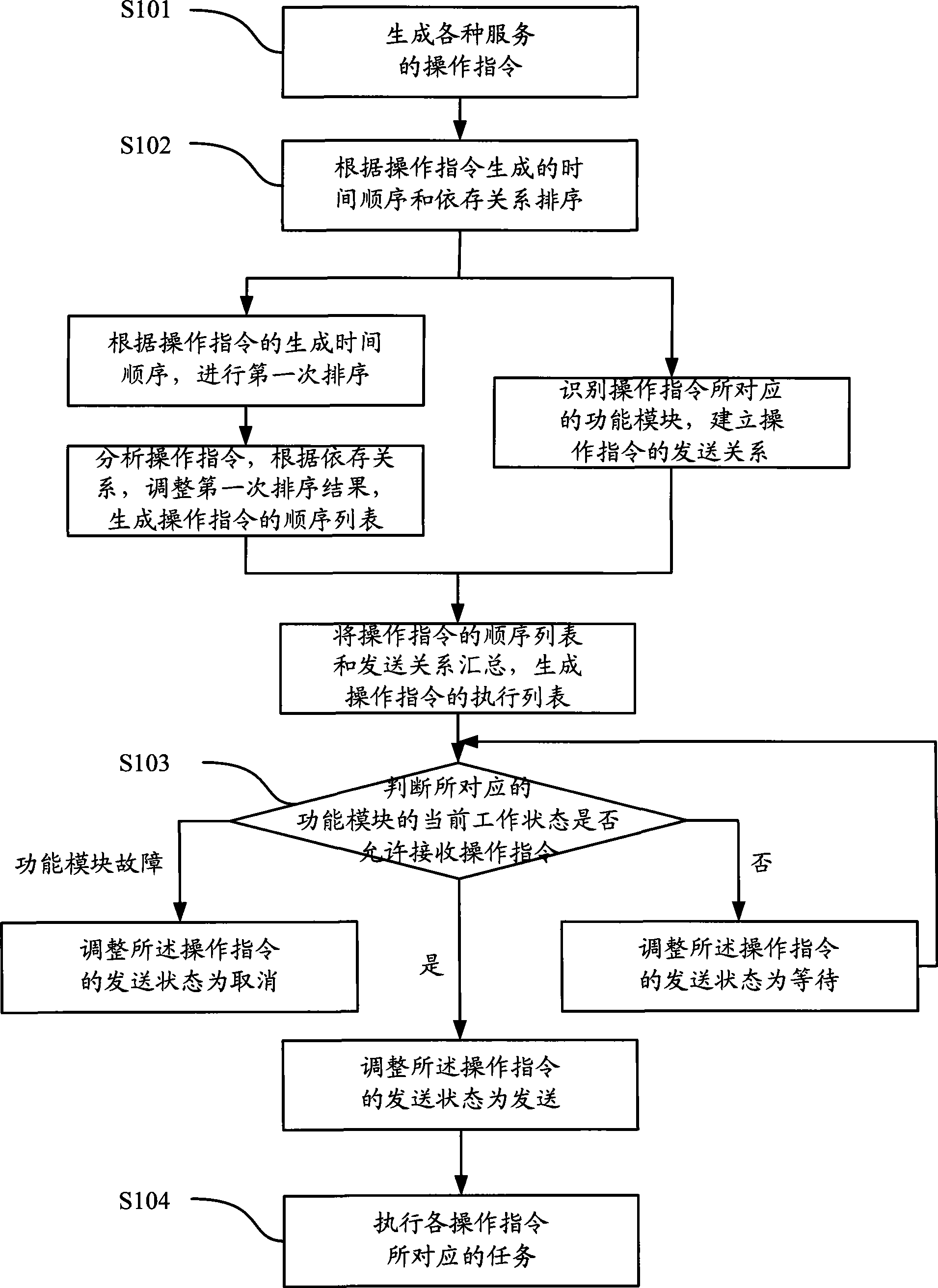

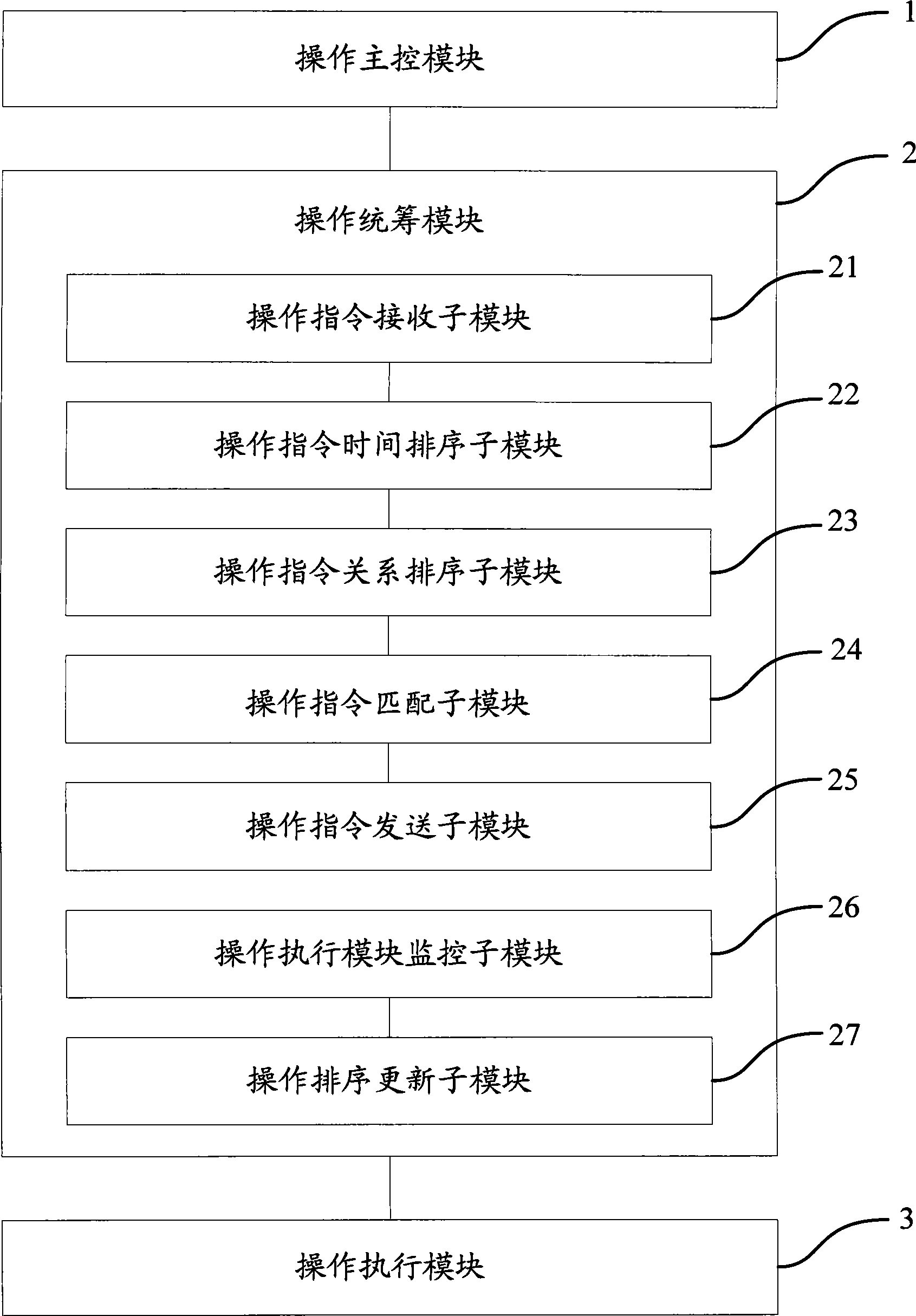

Multitask execution method in large software

InactiveCN101470625AAvoid redevelopmentImprove execution efficiencyMultiprogramming arrangementsChronological timeSoftware

The embodiment of the invention discloses a multi-task execution method in a large software, which comprises the following steps: generating operation instructions of various services, ordering the operation instructions to generate an execution list of the operation instructions according to the time sequence and the dependence relationship generated by the operation instructions, sending the operation instructions to relative functional modules according to the execution list of the operation instructions, and executing corresponding tasks of the operation instructions. Through using the method, a whole system is separated into different function modules according to task types, the tasks are executed by the function modules which correspond to the task types, thereby simplifying the maintenance work of the software, and increasing the execution efficiency of asynchronous instructions.

Owner:CHINA DIGITAL VIDEO BEIJING

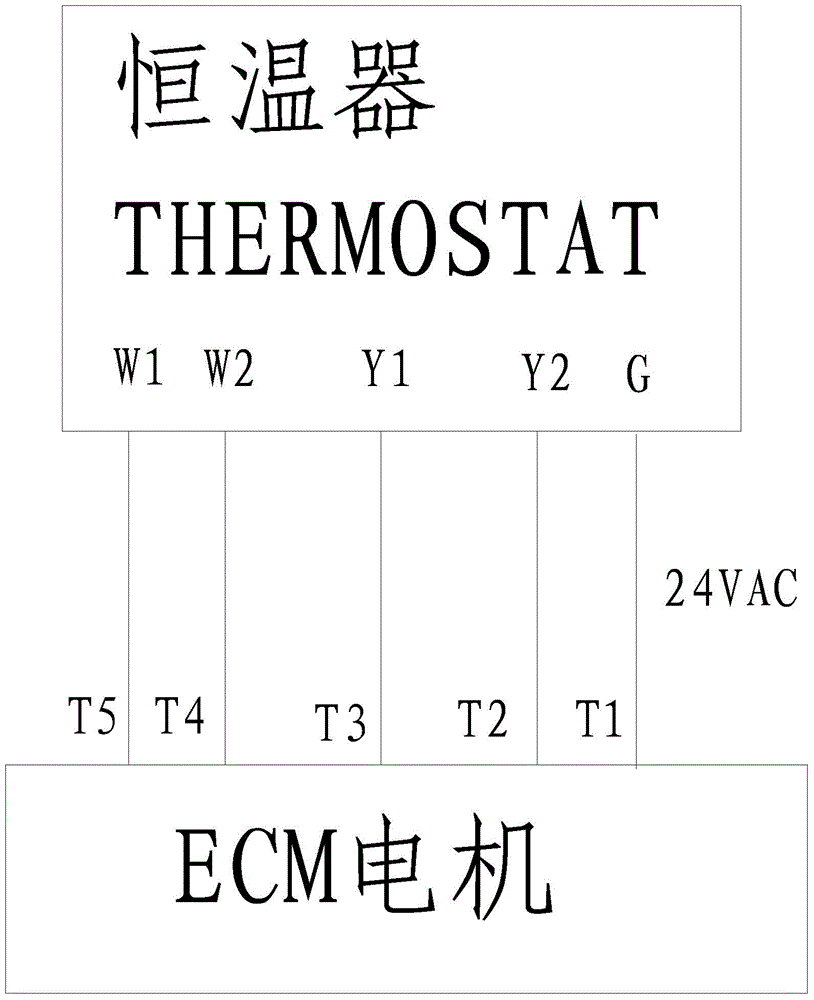

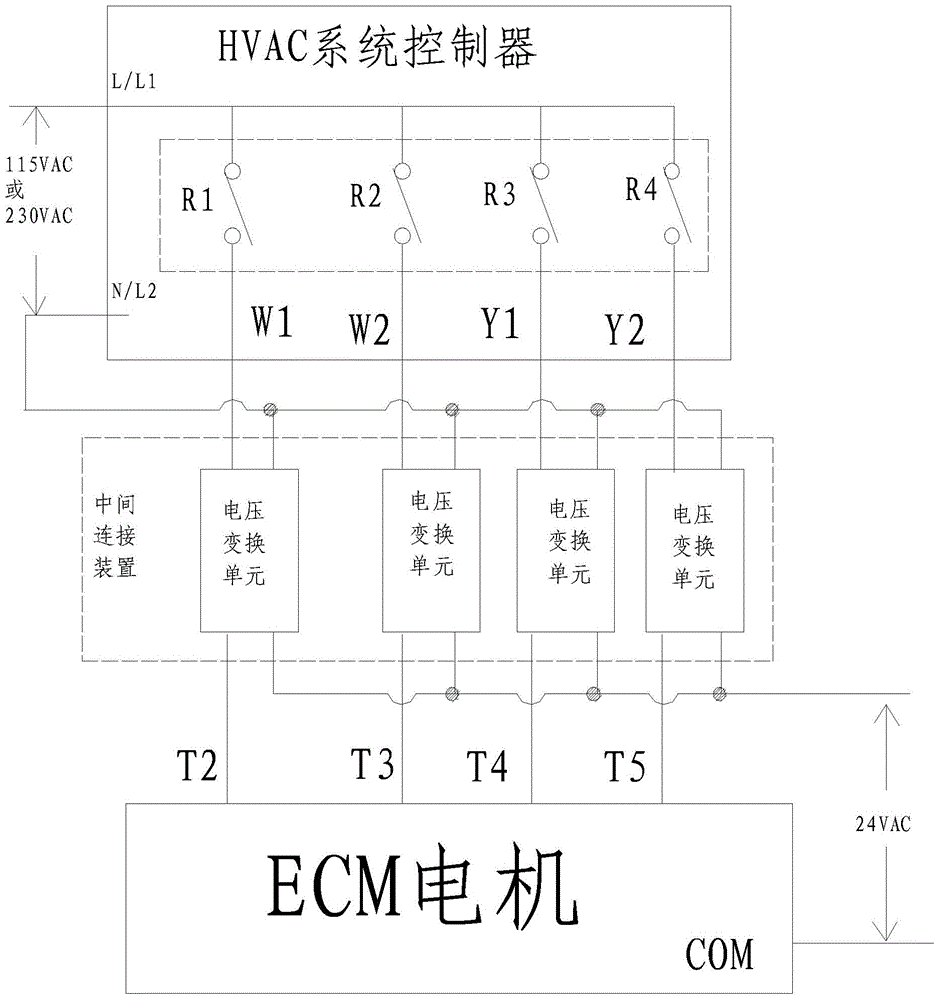

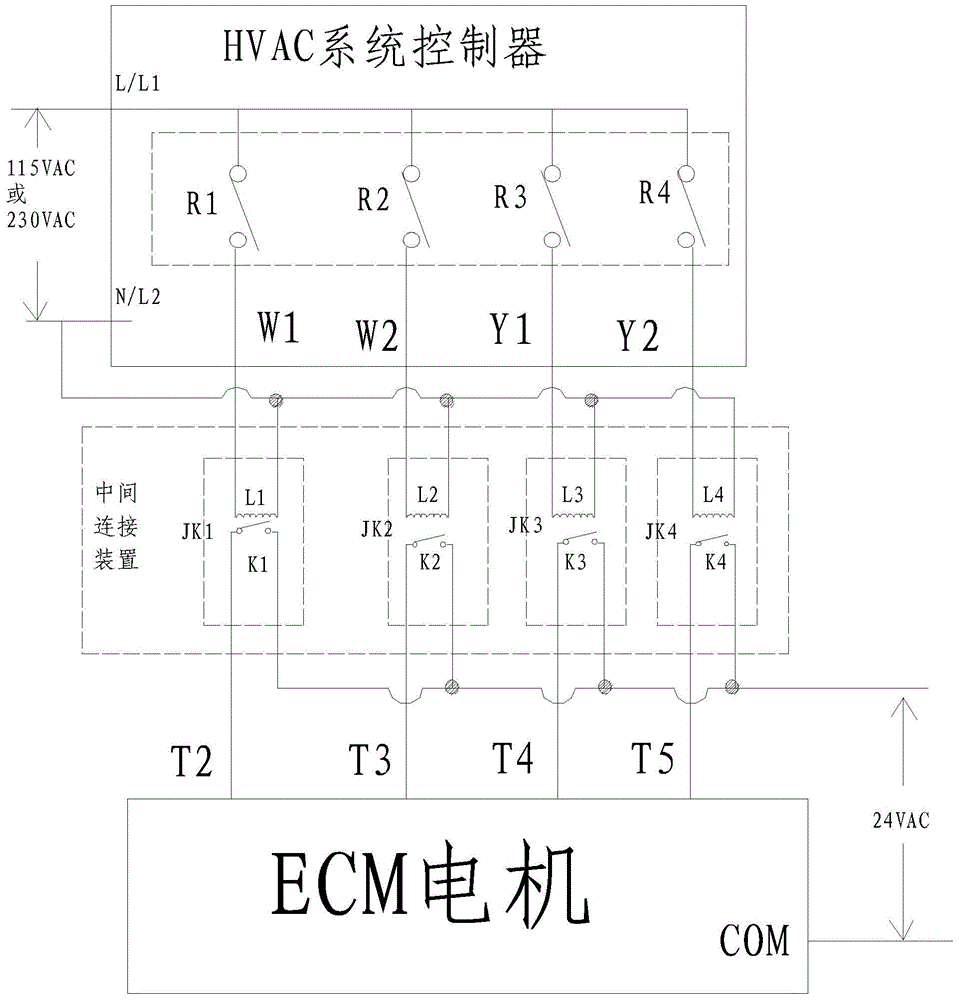

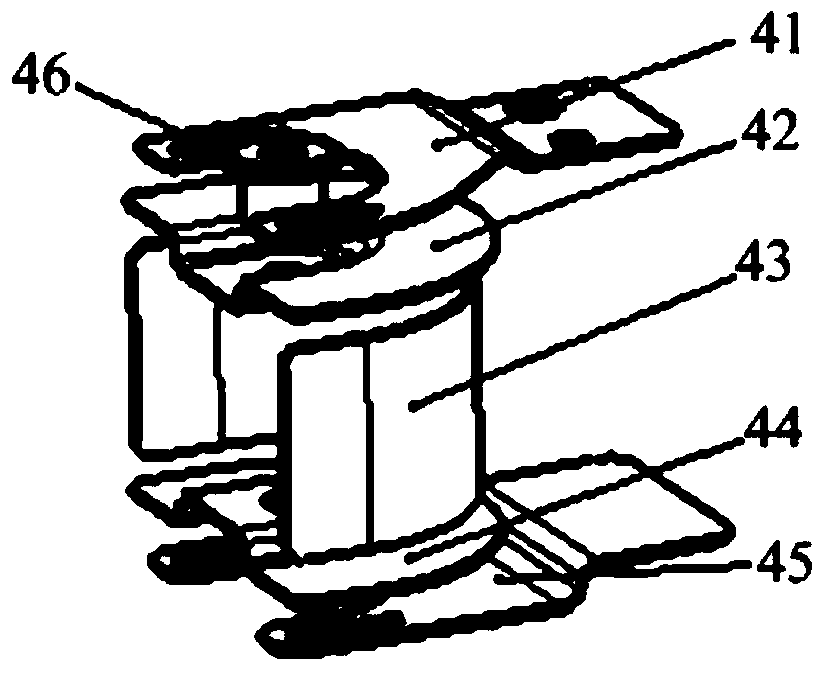

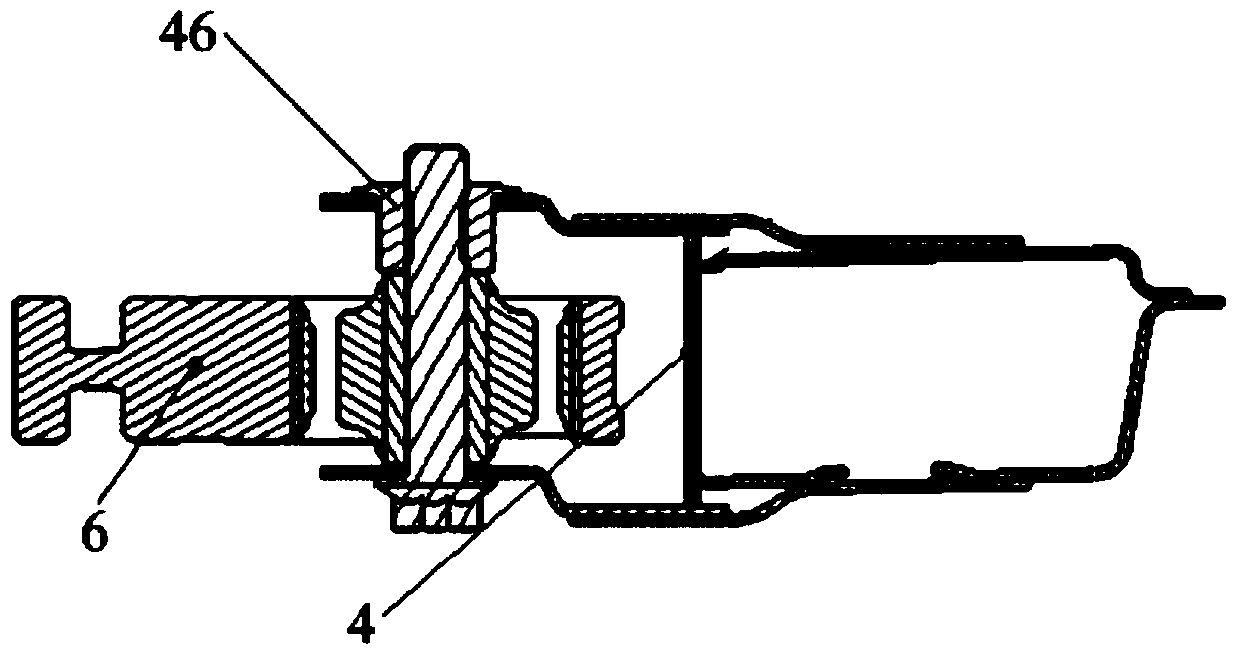

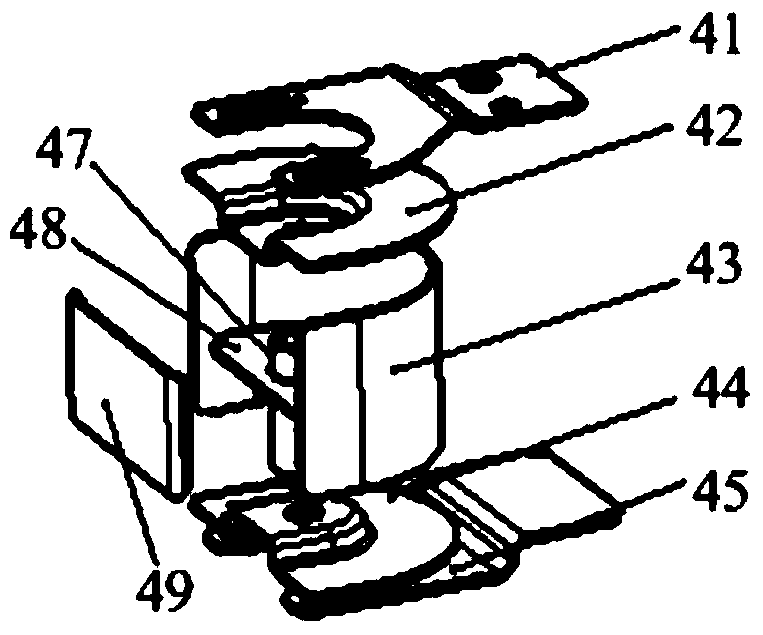

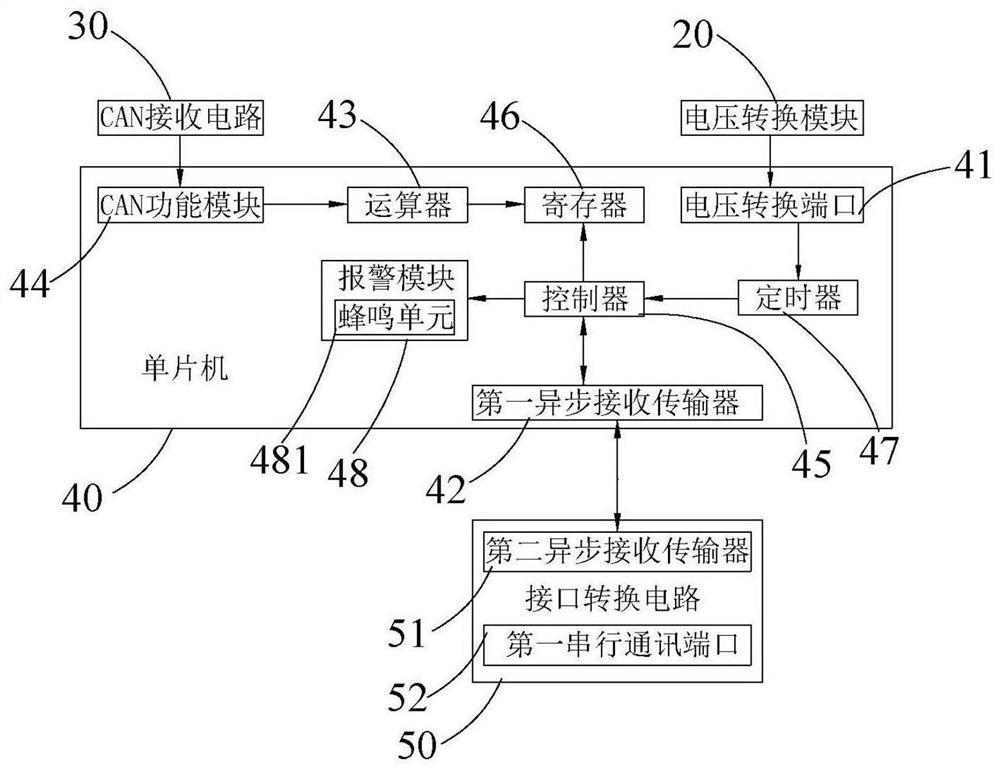

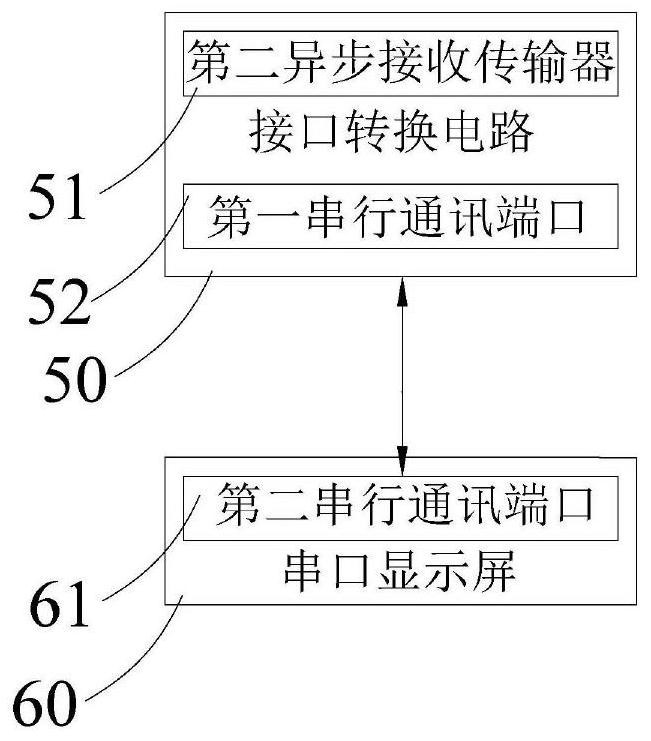

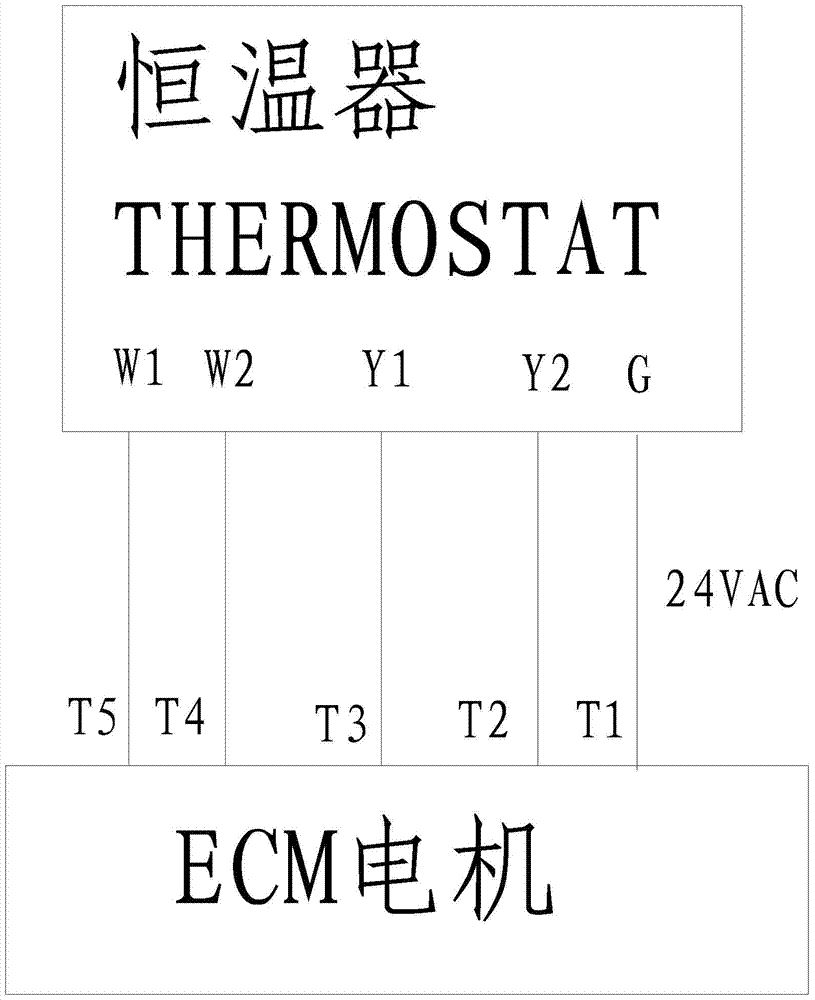

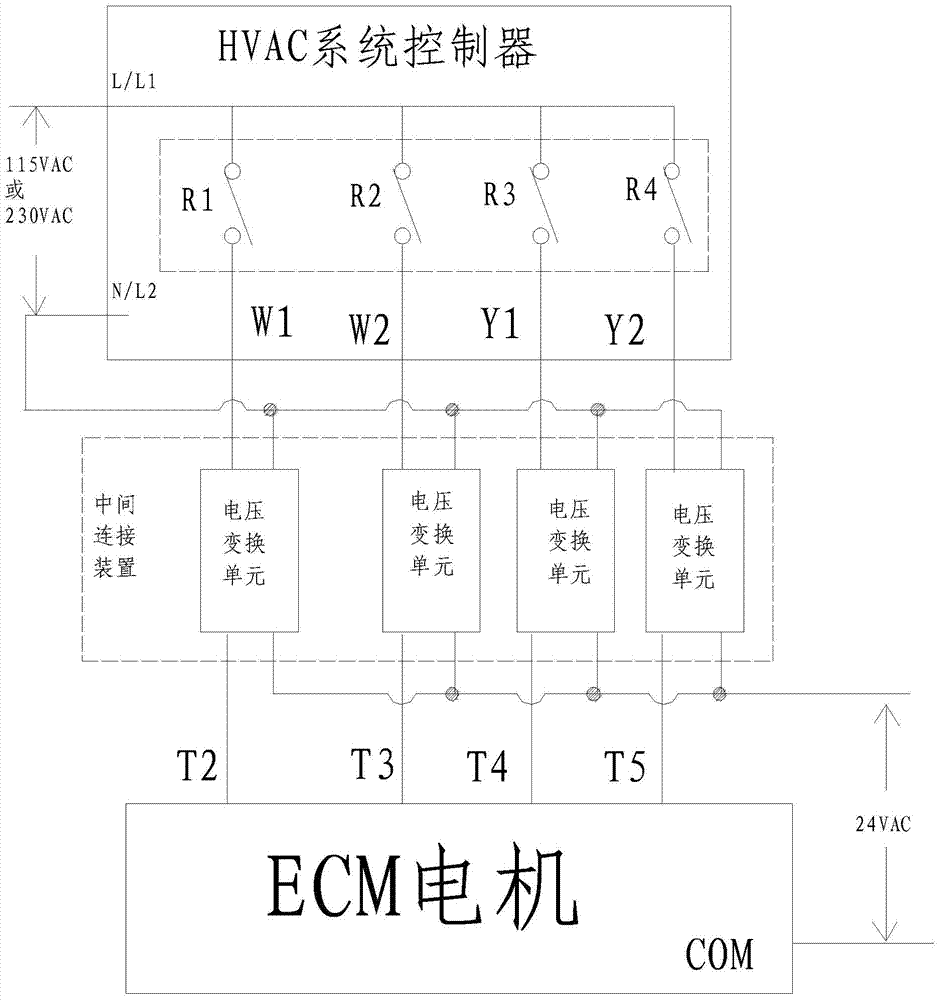

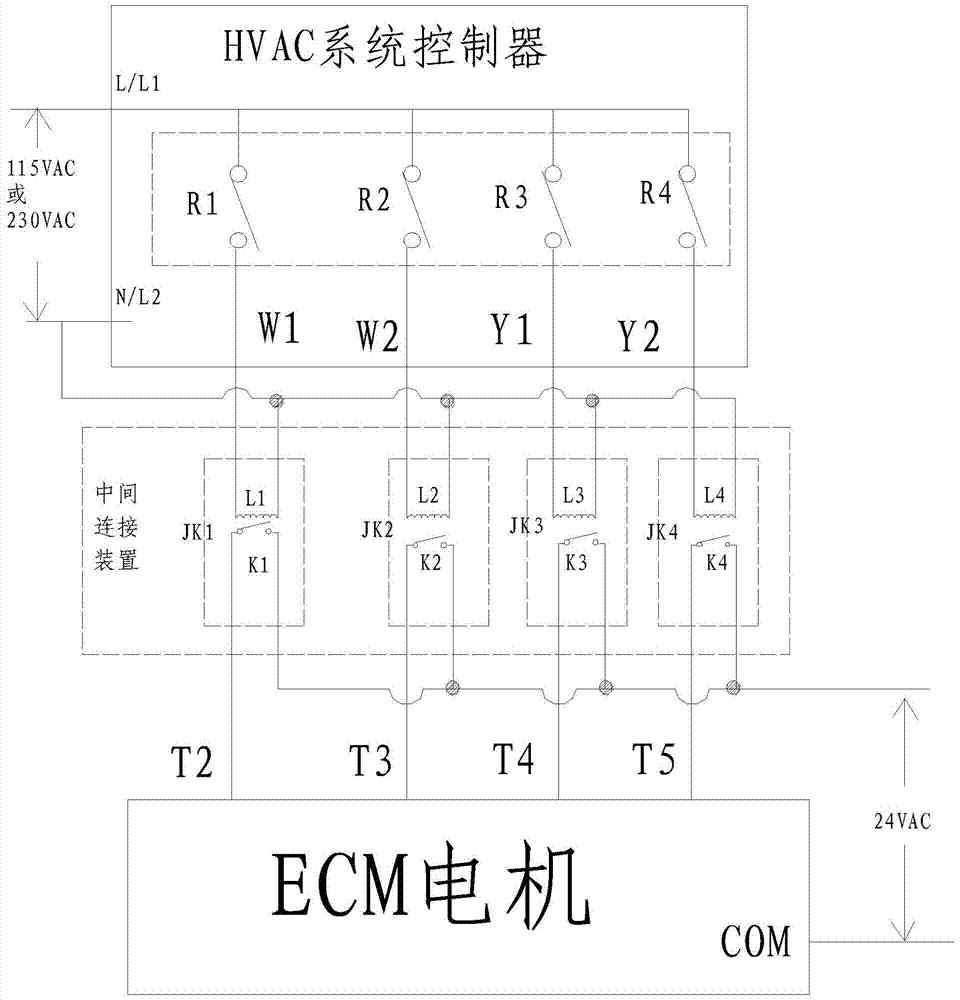

HAVC system and applied intermediate connecting device

ActiveCN105024593AAvoid redevelopmentReduce R&D costsSingle motor speed/torque controlLow voltageAlternating current

An HVAC system and an intermediate connection apparatus applied in the system. In the HVAC system, a PSC motor is replaced by an ECM. The HVAC system comprises an HVAC system controller. The HVAC system controller is provided with a plurality of 115V or 230V alternating-current output ports (W1, W2, Y1, Y2) connected to the motor, and one common port. The ECM is provided with a plurality of 24V low-voltage alternating-current gear input lines, operating parameters of the motor are selected according to the selected gear input lines in a closed state. The HVAC system also comprises an intermediate connection apparatus. The intermediate connection apparatus is connected between the HVAC system controller and the ECM. The intermediate connection apparatus converts 115V or 230V alternating-current electric signals of the plurality of output ports of the HVAC system controller into 24V low-voltage alternating-current signals capable of being identified by the plurality of gear input lines of the ECM. In this way, redevelopment is avoided, research and development costs are reduced, the number of product models is reduced and management is facilitated.

Owner:ZHONGSHAN BROAD OCEAN

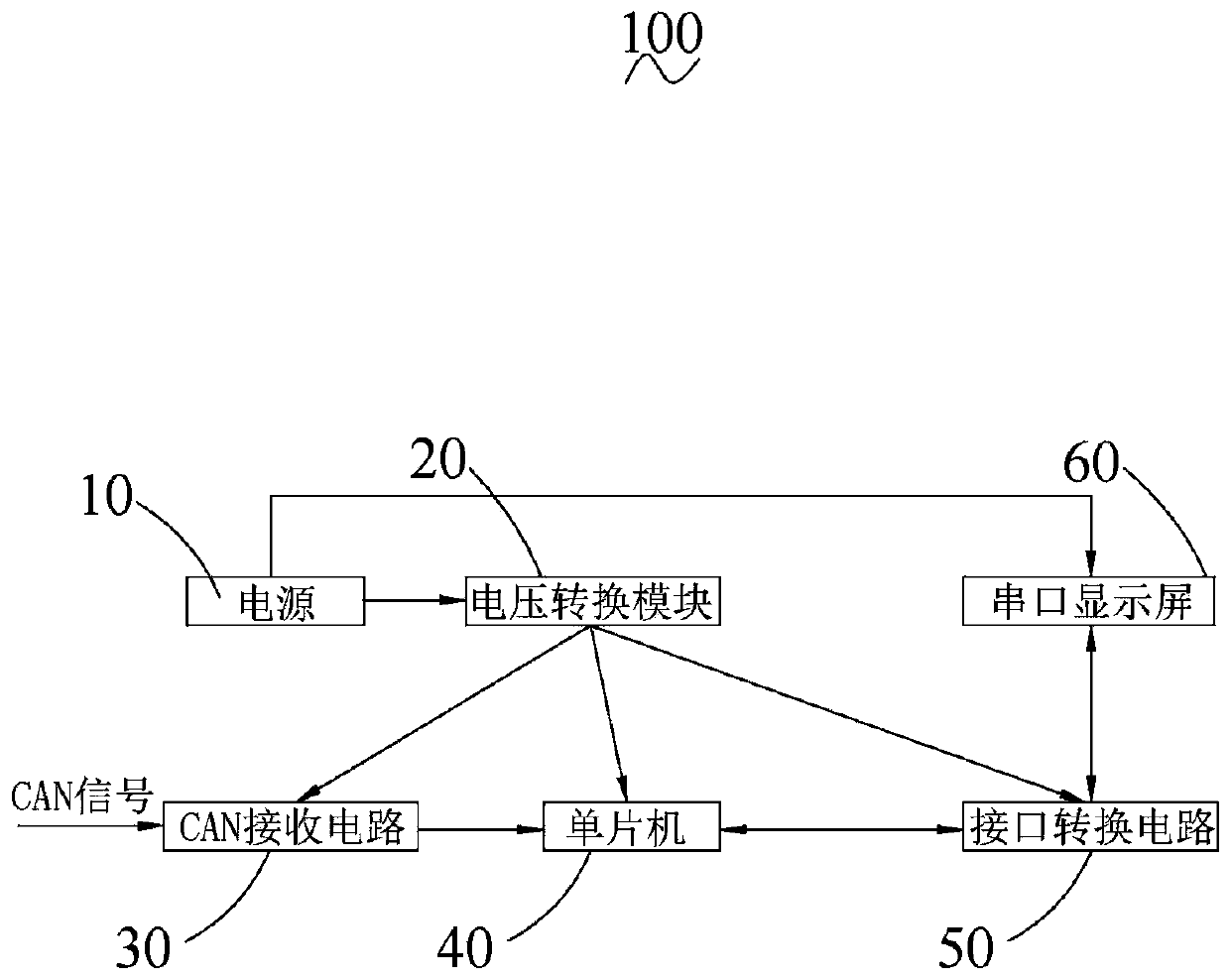

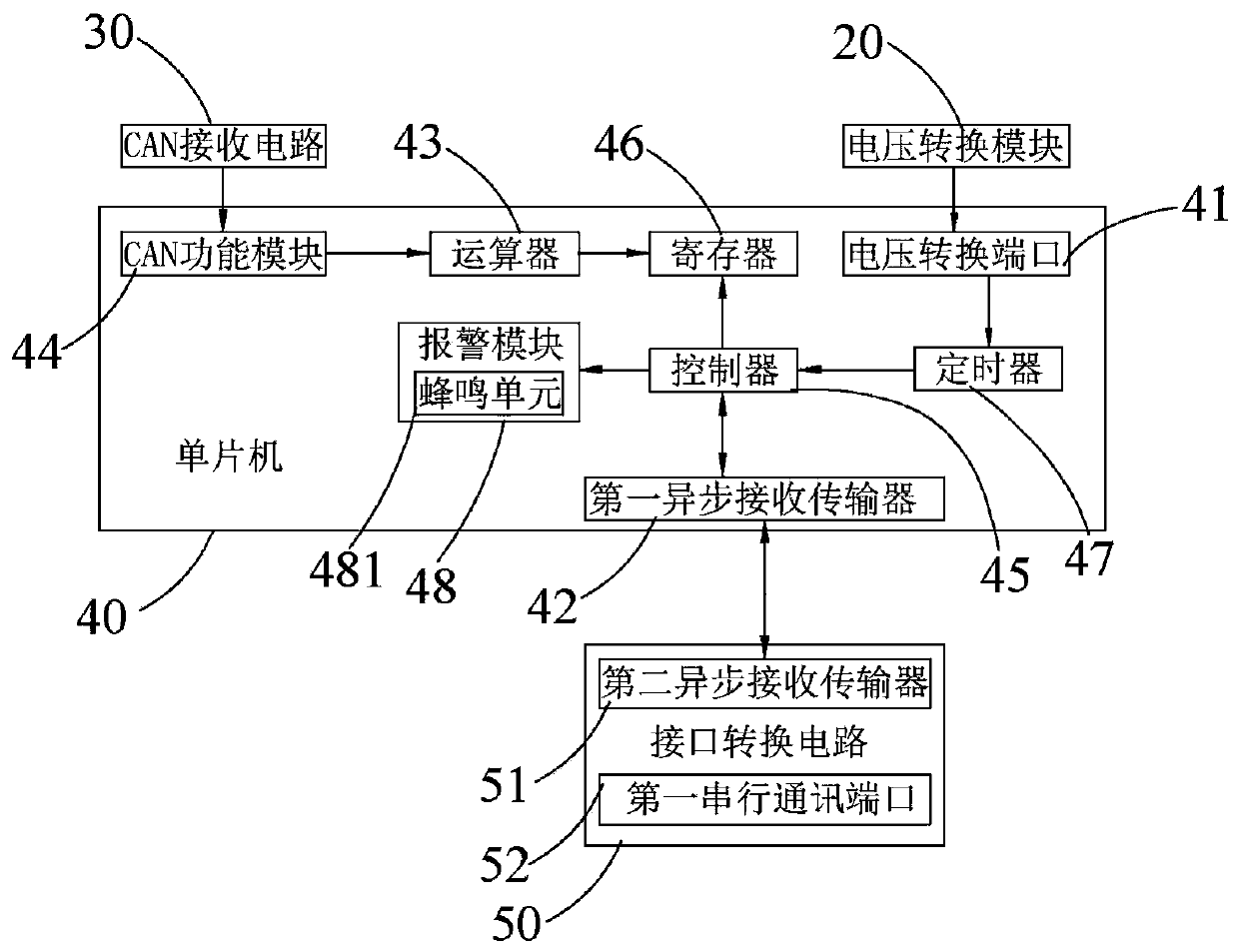

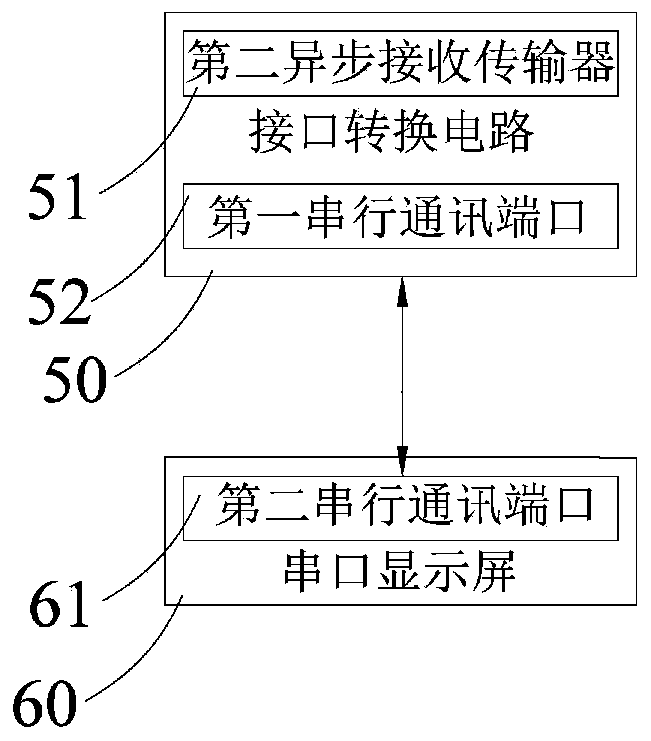

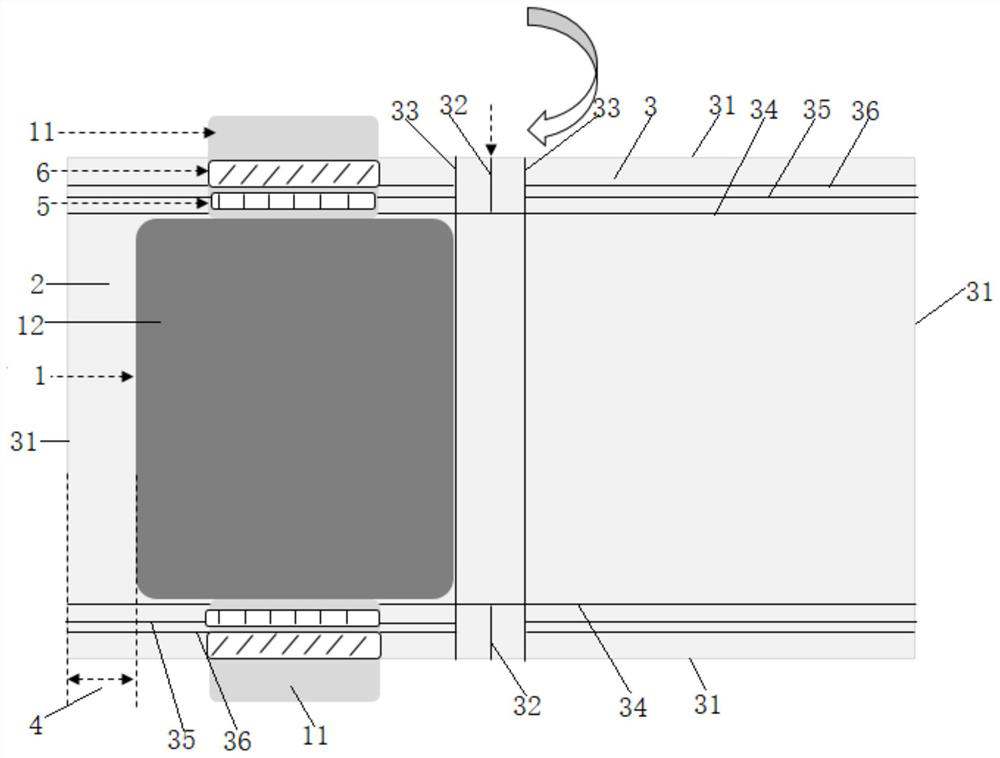

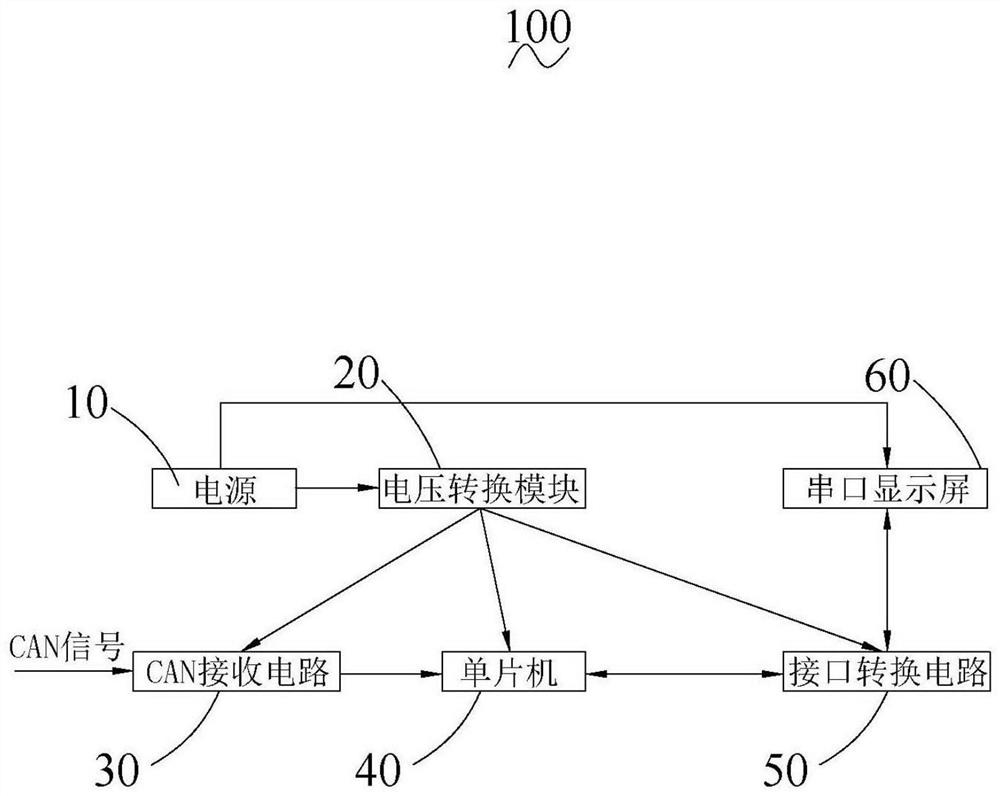

Battery pack information display device and method

ActiveCN111026074AAvoid redevelopmentFully reflect status informationElectric testing/monitoringVehicular energy storageDisplay deviceHemt circuits

The invention discloses a battery pack information display device, which comprises a power supply, a voltage conversion module, a CAN receiving circuit, a single chip microcomputer, an interface conversion circuit and a serial port display screen, wherein the power supply is respectively connected with the voltage conversion module and the serial port display screen; the voltage conversion moduleis respectively connected with the CAN receiving circuit, the single-chip microcomputer and the interface conversion circuit; the serial port display screen is connected with the interface conversioncircuit; the interface conversion circuit is connected with the single-chip microcomputer; the single-chip microcomputer is connected with the CAN receiving circuit; and the CAN receiving circuit is used for receiving CAN signals sent by a battery pack. The beneficial effects are that the CAN signals are analyzed through the single-chip microcomputer, the analyzed battery information data is transmitted to the serial port display screen to be displayed, the state information of the battery pack can be comprehensively reflected, hardware of the original battery pack is not changed, the redevelopment of a BMS is avoided, the cost is saved, only the CAN signals are analyzed, programs are designed in a modular mode, the structure is simple, and the expansion is easy.

Owner:ANHUI LVWO RECYCLING ENERGY TECHNOLOGY CO LTD

Soft package lithium ion cell packaging method

ActiveCN112952207ASave costSave the customization cycleFinal product manufactureSecondary cellsPlastic filmLithium-ion battery

A soft package lithium ion battery cell packaging method belongs to the technical field of battery cell packaging, and comprises the following steps: 1) measuring the size of a bare battery cell, and cutting an aluminum plastic film meeting the size requirement according to the size of the bare battery cell and the size reserved for packaging; 2) drawing a broken line graph of the aluminum plastic film on the drawing template, and punching at the intersection point of the broken line graph; (3) placing the drawing template on the cut aluminum plastic film, drawing points along the holes in the drawing template, manually forming folding marks in the point drawing positions on the aluminum plastic film, and then trimming; and 4) putting the bare battery cell into the aluminum plastic film with a folded pit, and carrying out hot-pressing packaging and liquid leakage test. The method has the beneficial effects that a manual pit making method is used for replacing a customized mold pit punching method or a direct packaging method, the method is suitable for packaging the soft package lithium ion battery cells of various sizes, new mold redevelopment is avoided, the production cycle is shortened, the manufacturing cost is reduced, the packaging effect is improved, and the liquid leakage risk is reduced.

Owner:WUHU ETC BATTERY LTD

Industrial data monitoring system based on embedded modularization platform

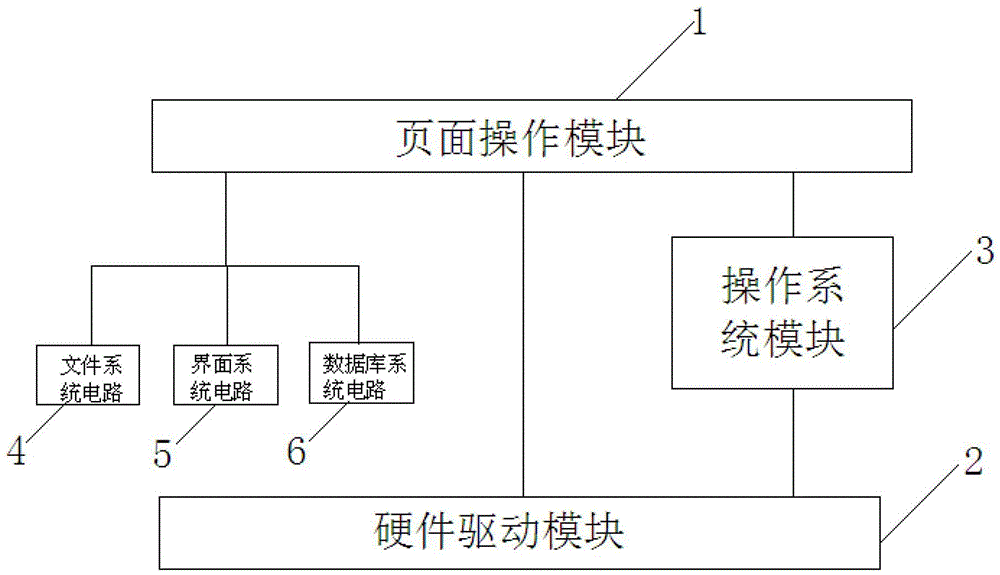

ActiveCN103279105BReduce development costsImprove work efficiencyTotal factory controlProgramme total factory controlElectricityKey pressing

The invention discloses an industrial data monitoring system based on an embedded modularization platform. The industrial data monitoring system comprises a man-machine interaction module for displaying and inputting signals through keys, a power panel module for supplying electricity, and a relay switch module for outputting the signals. The man-machine interaction module comprises a hardware driving module, an operating system module and a page operation module which are sequentially connected. Through design of the embedded universal platform, when new hardware is added, what is needed is that the interface of the page operation module is modified aiming at products, the fact that uniform code foundation frames can be used in an industrial instrument platform is realized, top layer codes of an applied part need to be modified in research and development of different products, the same format is adopted in interfaces, the interfaces do not influence one another, regardless of the fact that one interface or multiple interfaces operate in the system, no influences are caused on stability of the system itself and the foundation frame except applied layers, and an inner core always needs no modification to avoid the problem that all parts need to be redesigned when new products are developed in the past.

Owner:WUHAN CREATION ELECTRICAL AUTOMATION

New energy vehicle, and power supply method and power supply system for new energy vehicle

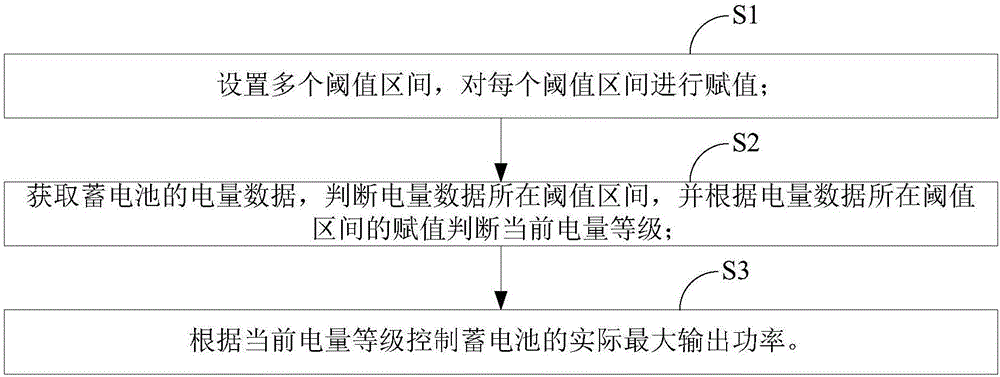

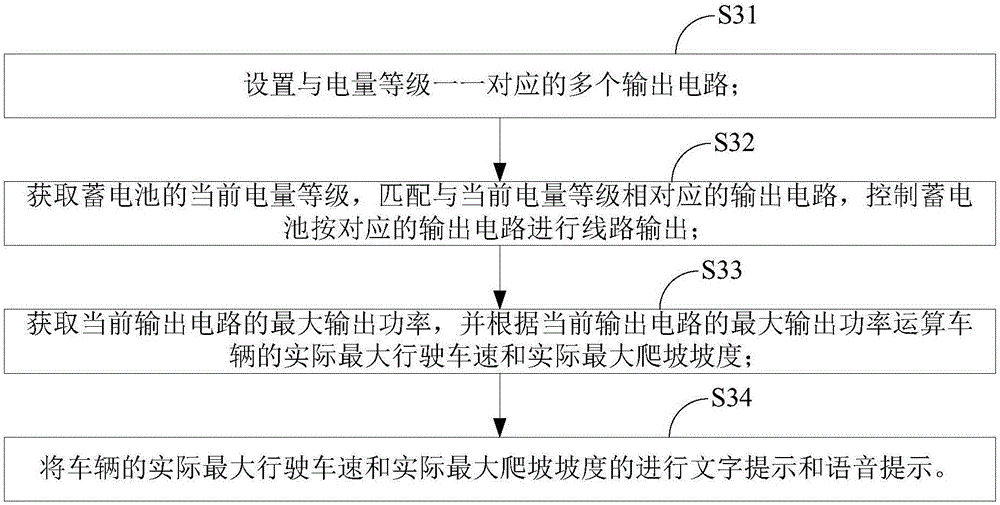

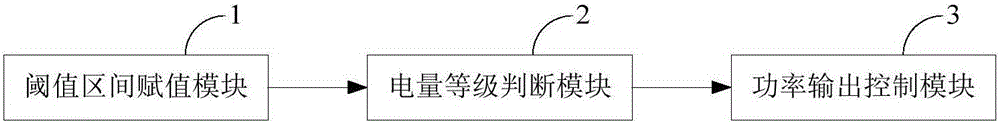

InactiveCN106828158AExtended service lifeAvoid redevelopmentVehicular energy storageBattery/fuel cell control arrangementCurrent electricNew energy

The invention discloses a new energy vehicle, and a power supply method and a power supply system for the new energy vehicle. The power supply method includes setting a plurality of threshold intervals and assigning values for each threshold interval; acquiring electric quantity data of storage batteries, judging the threshold intervals where the electric quantity data are located and judging current electric quantity class according to the assigned values; controlling actual maximum output power of the storage batteries according to the current electric quantity class. The power supply system comprises a threshold interval value assigning module, an electric quantity class judging module and a power output control module. The new energy vehicle, the power supply method and the power supply system have the advantages that threshold intervals are set to classify power quantities, so that the maximum output power of the storage batteries can be controlled, power can be supplied by the storage batteries at different levels of output power under the conditions of the different electric quantities, excessively fast discharge due to excessively high output power can be prevented, and the service lives of the storage batteries can be advantageously prolonged; the values are assigned for the threshold intervals, the electric quantities are classified according to the assigned values, value assignment intervals can be adjusted, accordingly, the new energy vehicle, the power supply method and the power supply system can adapt to different types of storage batteries, and the power supply system does not need to be developed again when the storage batteries are replaced.

Owner:HUBEI UNIV OF ARTS & SCI

Multitask execution apparatus in large software

InactiveCN101470624AAvoid redevelopmentImprove execution efficiencyMultiprogramming arrangementsComputer scienceSoftware

The embodiment of the invention discloses a multi-task executive device in a large software, which comprises an operation main control module, an operation overall planning module and an operation executive module, wherein the operation main control module is used to generate operation instruction of various services, the operation overall planning module is used to generate the time sequence and the dependence relationship of the operation instruction according to the operation main control module, thereby ordering the operation instruction, generating an executive list of the operation instruction, and sending various operation instructions to the operation executive module. The operation executive module is used to execute tasks which correspond to the operation instruction which is sent by the operation overall planning module. Through the multi-task executive device, a whole system is separated into different operation executive modules according to task types, the operation executive modules which correspond to the task types execute the tasks, thereby simplifying the maintenance work of the software, and increasing the execution efficiency of asynchronous instructions.

Owner:CHINA DIGITAL VIDEO BEIJING

Working method of a configurable multi-port universal data bridge system

ActiveCN106598885BAvoid redevelopmentAvoid concatenationElectric digital data processingSpecific functionData system

The invention belongs to the field of communication technology and provides a configurable multiport general data bridging system and a working method thereof. The system comprises a hardware part and a software part for achieving a specific function; the hardware part comprises a plurality of data communication ports, a storage unit and a main control unit, wherein the data communication ports have data transmitting and receiving functions and are used for receiving and transmitting data frames; the storage unit is used for storing needed data and files; the main control unit is used for running the software part and coordinating running of the data communication ports and the storage unit to complete the data bridging process; the software part comprises a configuration file, a data frame cache queue, a data protocol package, a control program and a database. Different data systems can be bridged, and a data bridging scheme which is lower in cost and more convenient to use is provided.

Owner:HUAZHONG UNIV OF SCI & TECH

Engine rear suspension combination module and automobile front subframe assembly assembly

ActiveCN106553520BAvoid redevelopmentShorten the development cycleUnderstructuresJet propulsion mountingVehicle frameEngineering

The invention provides an engine rear mounting combined module and an automobile front auxiliary frame assembling assembly. The engine rear mounting combined module is formed by a module body arranged in an overlapped area between a three-point rear and a four-point rear mounting of a back transverse beam of the automobile front auxiliary frame, a first connection part connected with a three-point engine rear mounting pull rod and a second connection part connected with a four-point engine rear mounting support, wherein the first connection part is arranged on the module body; and the second connection part is arranged on the module body. The engine rear mounting combined module is arranged in the overlapped area between the three-point rear and the four-point rear mounting of the back transverse beam; by the use of the first connection part, rear mounting matching with the four-point mounting engine is achieved; by the use of the second connection part, rear mounting matching with the three-point mounting engine is achieved; and re-development of the whole front auxiliary frame can be avoided, so developing period and cost can be reduced.

Owner:GREAT WALL MOTOR CO LTD

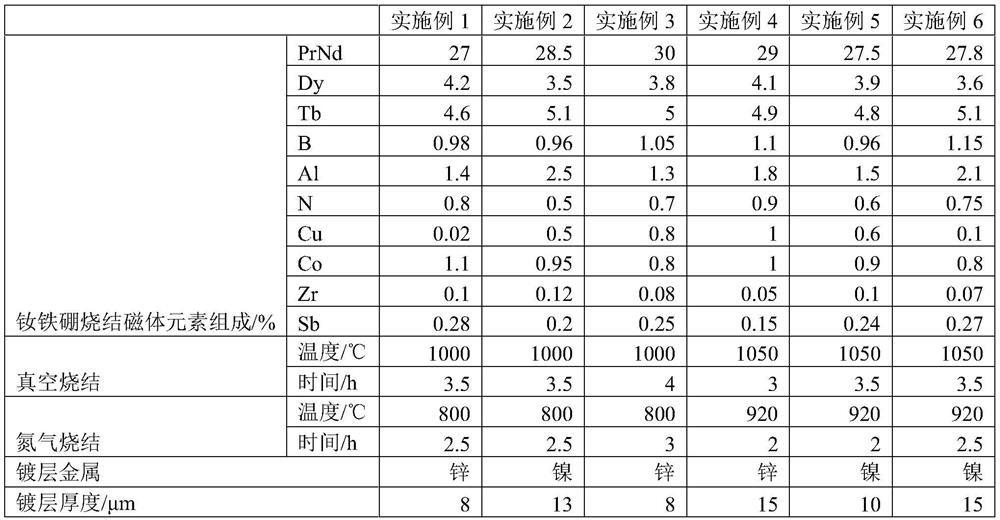

A kind of anti-corrosion NdFeB magnet and preparation method thereof

ActiveCN110310795BImprove protectionImprove anti-corrosion performancePermanent magnetsMagnetic materialsMetallic aluminumAluminium hydroxide

The invention relates to a sintered NdFeB magnet with a coating and discloses an anticorrosive neodymium iron boron magnet and a preparation method thereof. The anticorrosive neodymium iron boron magnet includes a neodymium iron boron sintered magnet and an anticorrosive coating at an outer side of the sintered magnet, wherein the neodymium iron boron sintered magnet contains elements of 1.3-2.5 wt% of Al and 0.5-0.9 wt% of N, more than 90% of the N element is present in the NdFeB sintered magnet in the form of AlN, the AlN exists in the form of adhesion on a surface of the NdFeB sintered magnet and walls of internal pores, the anti-corrosion coating is combined with the AlN, the anti-corrosion coating is composite coating of aluminum hydroxide and plating metal, and the plating metal is zinc or nickel. Aluminum metal is utilized as an aluminum source, after the NdFeB is sintered and is transformed under a high temperature environment of nitrogen, the continuous AlN is uniformly formedon the surface of the NdFeB sintered magnet, the protective effect of the anti-corrosion coating is improved by the synergistic effect of the AlN and the anti-corrosion coating, anti-corrosion performance of the anti-corrosion coating after being broken is further improved, for NdFeB magnet products in the prior art, formulation adjustment is reduced, R&D efficiency is improved, and product update is accelerated.

Owner:宁波合力磁材技术有限公司

A client-side synchronization-based multiplayer game access control method on the xbox platform

ActiveCN107930113BAvoid disruptionComplies with mandatory requirementsVideo gamesBusiness processMultiplayer game

Owner:SNAIL GAMES

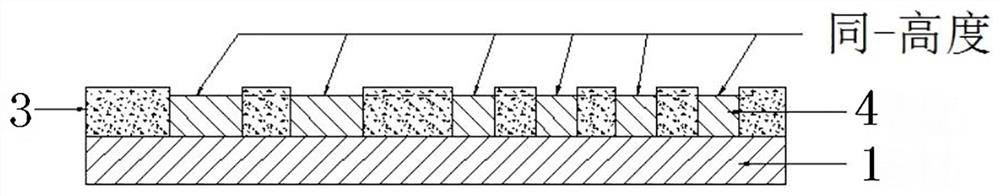

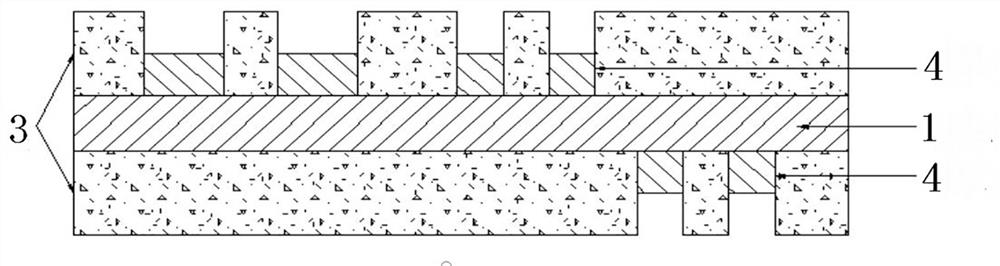

Stamping type stepped bonding pad PCB and manufacturing technology

PendingCN113316317AAvoid redevelopmentMake up for the lack of heightElectrical connection printed elementsPrinted element electric connection formationManufacturing technologyEngineering

The invention discloses and provides a stamping type stepped bonding pad PCB and a manufacturing technology. a part of PCB bonding pads have stepped height difference and are not on the same plane; and after the PCB is applied, conventional components can be adopted to realize a product design function, so that high redevelopment cost and time cost of the components are avoided. The stamping type stepped bonding pad PCB comprises a PCB base material, a circuit arranged on the PCB base material and solder resist ink or a covering film covering the circuit. The stamping type stepped bonding pad PCB further comprises a plurality of bonding pads which are electrically connected with the circuit and are not covered by the solder resist ink or the covering film; at least one bonding pad is a stamping type step bonding pad; a stamping boss is arranged on the upper surface of the stamping type stepped bonding pad; a concave cavity corresponding to the stamping boss is arranged in the lower surface of the stamping type stepped bonding pad; and a base material protrusion filled in the concave cavity is arranged on the PCB base material. The manufacturing technology is mainly characterized in that a boss is stamped on a bonding pad which needs to be heightened through die stamping on the PCB which is provided with the covering film and is not subjected to surface electroplating. The invention is applied to the technical field of PCB manufacturing.

Owner:ZHUHAI YUANSHENG ELECTRONICS SCI & TECH

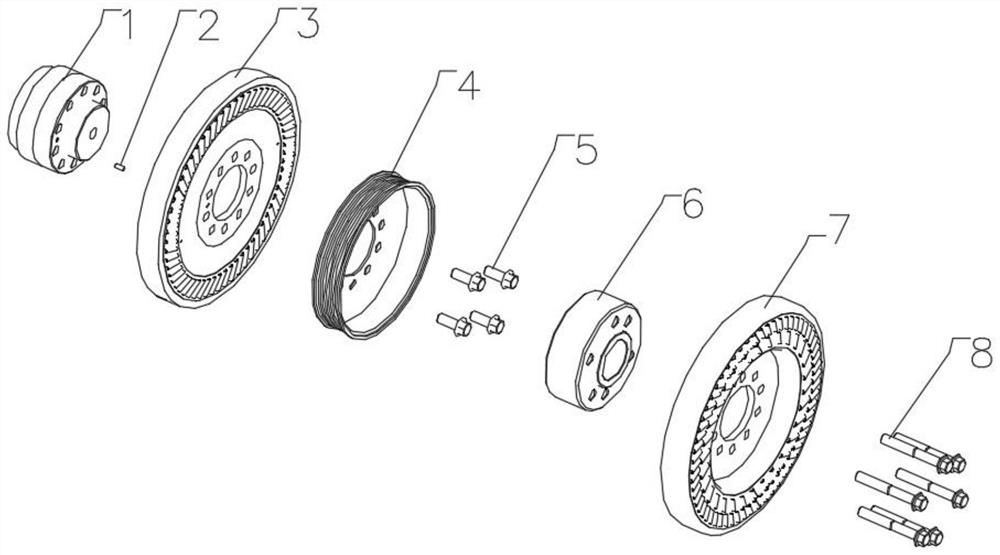

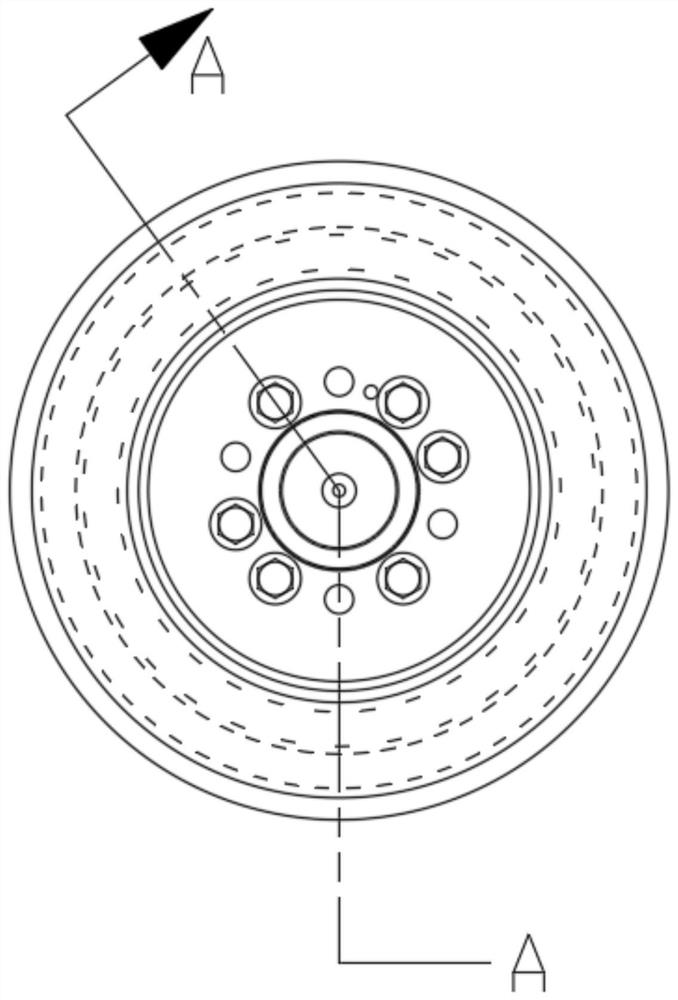

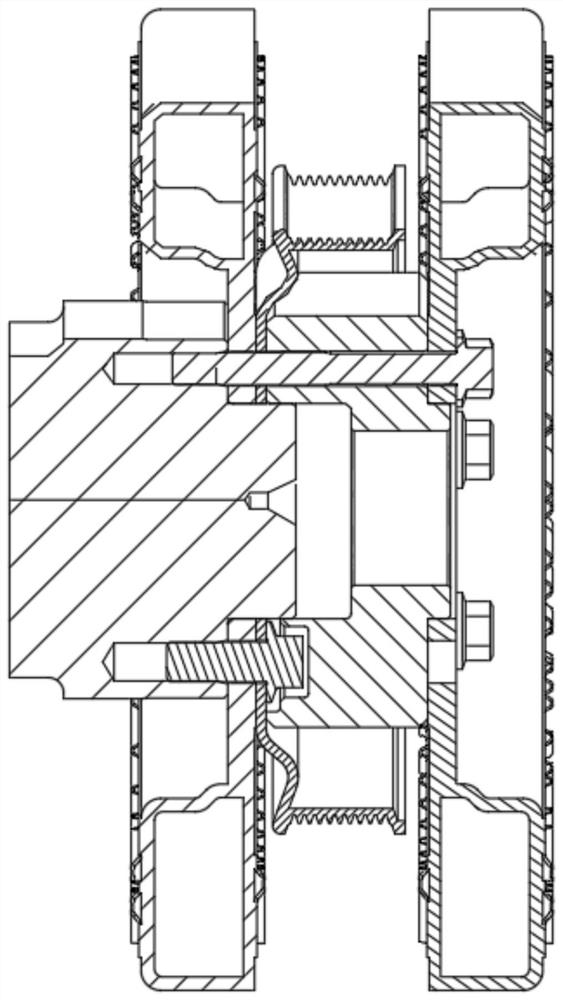

Two-stage torsional vibration damper of engine

PendingCN113339454ASolve the problem of torsional vibration overrunAvoid redevelopmentRotating vibration suppressionInertia force compensationDamperCylinder block

The invention discloses a two-stage torsional vibration damper of an engine. The two-stage torsional vibration damper comprises a crankshaft. The crankshaft, an inner side torsional vibration damper and a crankshaft belt pulley are arranged in a positioning manner through positioning pins, and the inner side torsional vibration damper and the crankshaft belt pulley are installed at the front end of the crankshaft through short bolts; and a connecting spacer block and an outer torsional vibration damper are sequentially placed at the front end of the crankshaft belt pulley and fixed to the crankshaft through long bolts. According to the two-stage torsional vibration damper, by means of a combined structure of the crankshaft and the two-stage torsional vibration damper, the problem that torsional vibration of the engine with a single-stage torsional vibration damper exceeds the limit can be rapidly solved, redevelopment of a large-specification torsional vibration damper, a mounting hole in a cylinder body, a front end gear train and surrounding parts is avoided, and the development time and development cost are greatly saved. The two-stage torsional vibration damper is suitable for the engine.

Owner:DONGFENG CUMMINS ENGINE

A reactor multiphysics coupling computing system and method

ActiveCN112364288BPreserve the second-order convergence rateAvoid redevelopmentComplex mathematical operationsNuclear reactorInterface layer

The invention discloses a reactor multi-physics field coupling calculation system and method, relates to the field of nuclear reactors, and solves the problem that there is no mature multi-physic field tight coupling calculation system. In the present invention, the system encapsulates and configures various calculation programs through the interface layer, and configures the corresponding calculation programs through the application program layer according to the type of reactor engineering calculation data; the interface layer is used to obtain restart data, and the restart data is the interface Layer imported reactor engineering calculation data, the interface layer constructs the necessary physics residual expressions for JFNK calculations based on the original physics of the calculation data used for calculation by Reactor Engineering at the application layer, and passes the physics residual equations to The core solution layer; the interface layer is used for transferring the physical field solution results between the core solution layer and the application layer. The invention can be used for program development, engineering design, accident analysis and evaluation of reactor engineering based on the concept of multi-physics coupling.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Simulation test method and server during application program development

ActiveCN106294179BImprove accuracyImprove efficiencySoftware testing/debuggingEncapsulated dataSoftware engineering

A simulation test method in an application program development process, comprising: after a request processing server receives a first pre-set type request sent by an application program to be tested of a development terminal, determining a first interface corresponding to the first pre-set type request according to an interface document of the application program to be tested; analysing a current switch state of the first interface; and if the current switch state is an on state, finding returned data corresponding to the first interface, determining a first format of the returned data corresponding to the first pre-set type request according to a mapping relationship between a pre-determined request type and the format of the returned data, packaging the returned data in accordance with the first format, and returning the generated first packaged data to the application program to be tested. The method effectively improves development accuracy and efficiency of an application program.

Owner:ONECONNECT TECH SERVICES CO LTD SHENZHEN

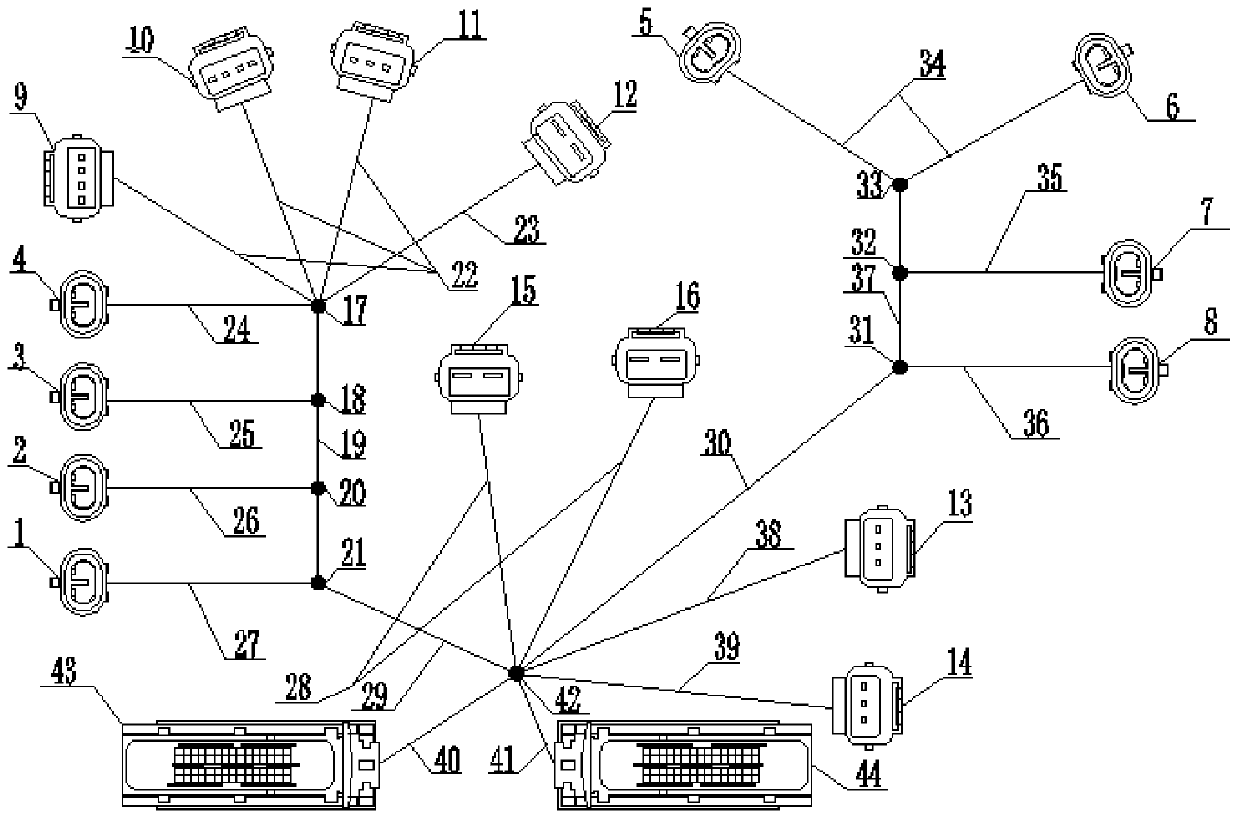

A V-shaped eight-cylinder dual-ecu electronically controlled engine wiring harness

ActiveCN105545476BMeet electrical performance requirementsEasy to assemble and disassembleMachines/enginesEngine componentsRail pressureCam

The invention provides a V-shaped eight-cylinder double-ECU electric engine harness. The V-shaped eight-cylinder double-ECU electric engine harness comprises a one-cylinder oil sprayer joint, a two-cylinder oil sprayer joint, a three-cylinder oil sprayer joint, a four-cylinder oil sprayer joint, a five-cylinder oil sprayer joint, a six-cylinder oil sprayer joint, a seven-cylinder oil sprayer joint, an eight-cylinder oil sprayer joint, an intake temperature pressure sensor joint, a machine oil temperature pressure sensor joint, a first rail pressure sensor joint, a crankshaft rotating speed sensor joint, a second rail pressure sensor joint, a cam shaft rotating speed sensor joint, a fuel metering unit sensor joint, a water temperature sensor joint and leads for respectively connecting with all the devices, and further comprises a first fulcrum, a second fulcrum, a third fulcrum, a fourth fulcrum, a fifth fulcrum, a sixth fulcrum, a seventh fulcrum, an eight fulcrum, a main ECU plug and a slave ECU plug. The V-shaped eight-cylinder double-ECU electric engine harness is simple in structural distribution, prevents renewed development of ECU under the precondition of satisfying use requirements, reduces the design cost and period, and improves the economy.

Owner:CHINA NORTH ENGINE INST TIANJIN

Information service security evaluation method and device

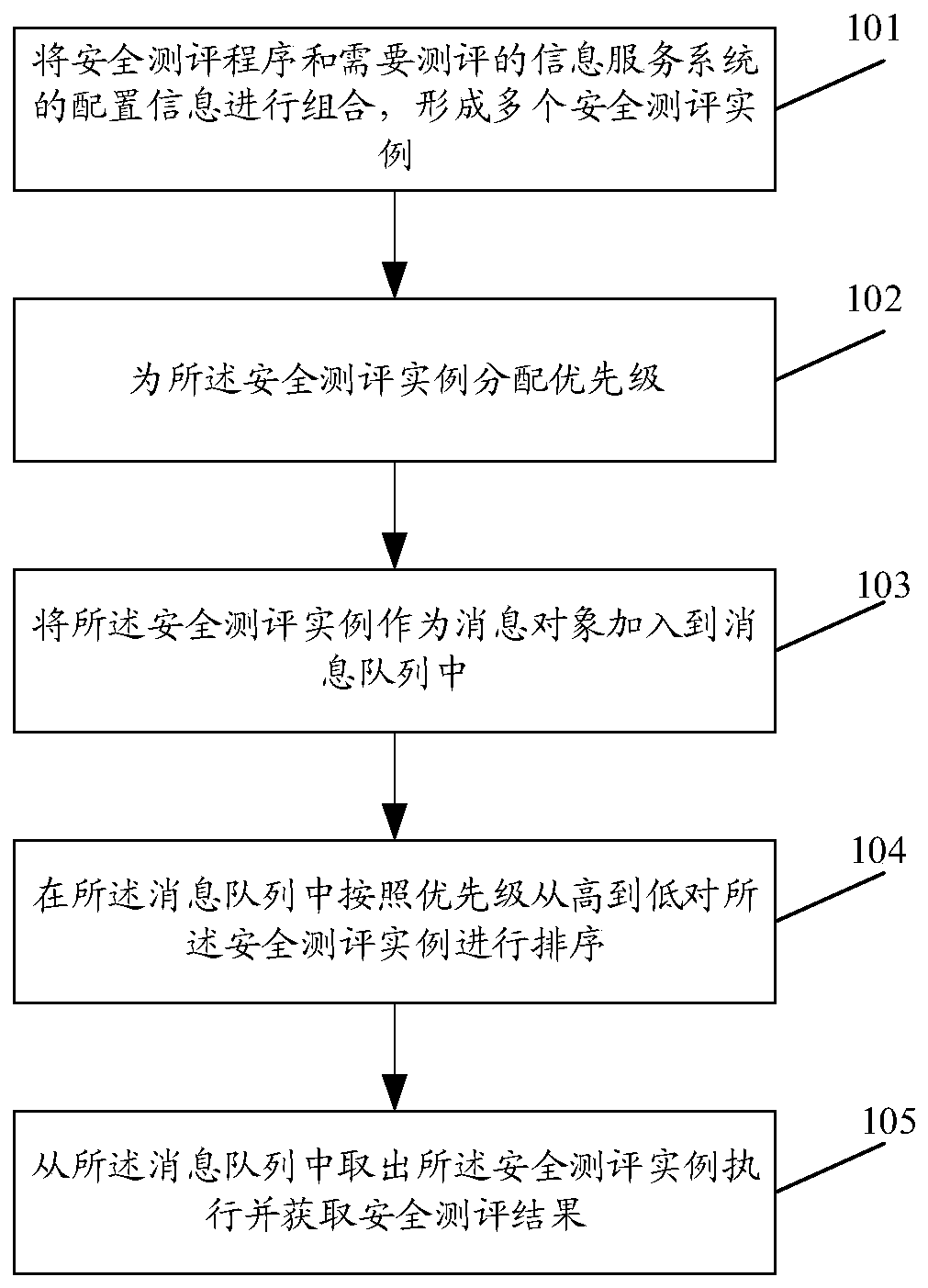

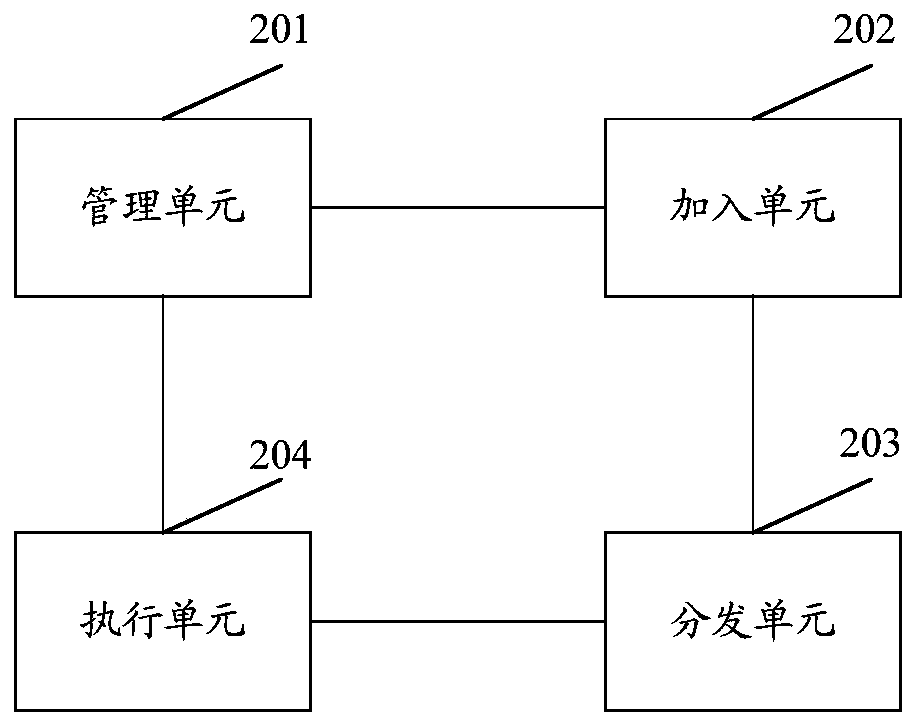

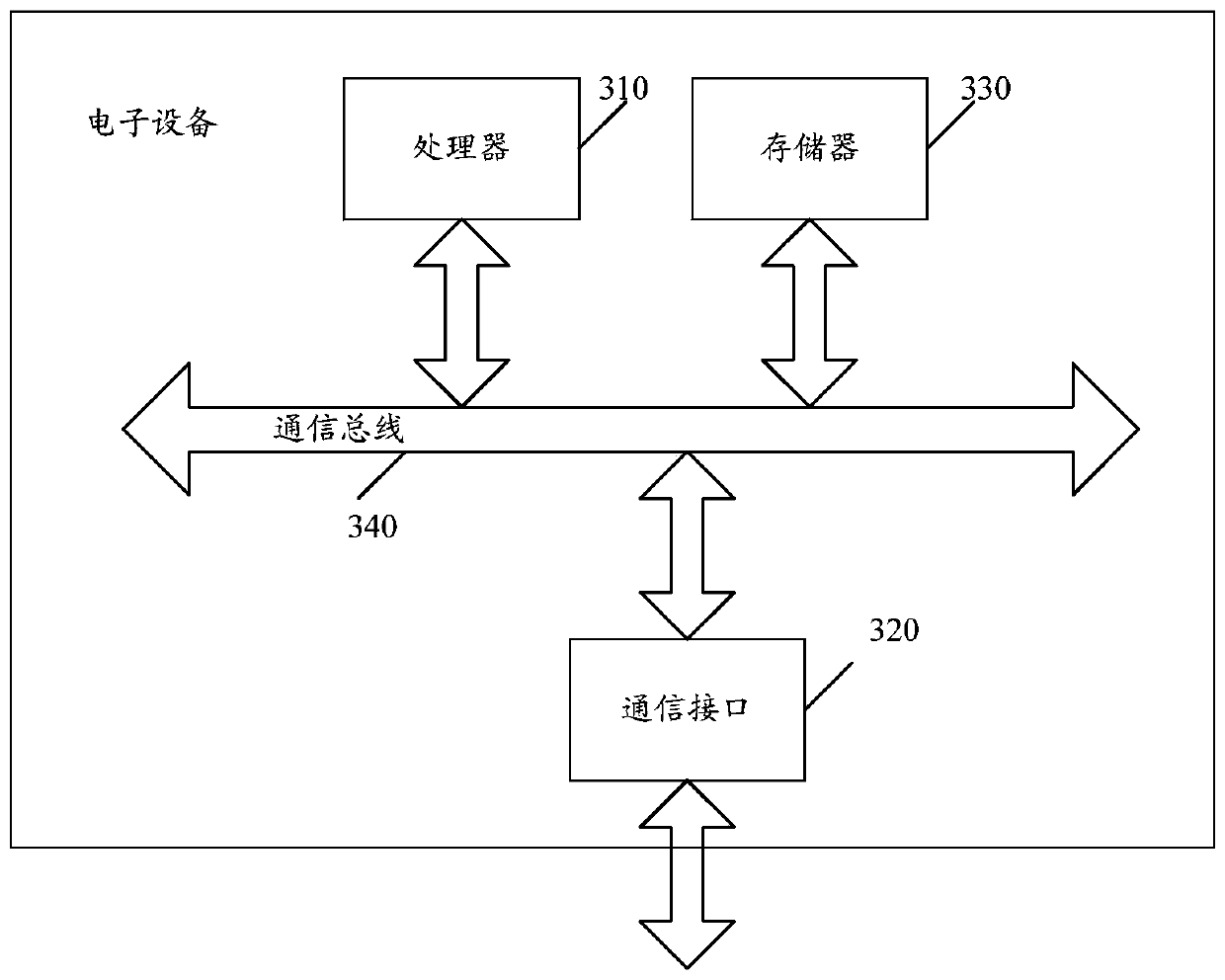

PendingCN111506898AConvenient for dynamic expansionRealize evaluationPlatform integrity maintainanceMessage queueEvaluation result

The invention provides an information service security evaluation method and device, and the method comprises the steps: combining a security evaluation program with the configuration information of an information service system needing to be evaluated, and forming a plurality of security evaluation examples; assigning a priority to each security evaluation instance; adding the security evaluationinstance into a message queue as a message object; sorting the security evaluation instances in the message queue according to priorities from high to low; and taking out the security evaluation instance from the message queue for execution and obtaining a security evaluation result. According to the method, information service security evaluation can be realized on the premise of easiness in use, high efficiency and low cost.

Owner:CHINA ACADEMY OF INFORMATION & COMM

A battery pack information display device and method

ActiveCN111026074BAvoid redevelopmentFully reflect status informationElectric testing/monitoringVehicular energy storageDisplay deviceHemt circuits

The invention discloses a battery pack information display device, comprising a power supply, a voltage conversion module, a CAN receiving circuit, a single-chip microcomputer, an interface conversion circuit and a serial port display; The receiving circuit, the single-chip microcomputer and the interface conversion circuit are connected, the serial port display is connected with the interface conversion circuit, the interface conversion circuit is connected with the single-chip microcomputer, the single-chip microcomputer is connected with the CAN receiving circuit, and the CAN receiving circuit is used to receive the CAN signal sent by the battery pack. The beneficial effects of the present invention are: the CAN signal is analyzed by the single-chip microcomputer, and the analyzed battery information data is transmitted to the serial port display screen for display, which can fully reflect the state information of the battery pack, without changing the hardware of the original battery pack, and avoiding redevelopment BMS, which saves costs, only analyzes CAN signals, and the program adopts modular design, which is simple in structure and easy to expand.

Owner:ANHUI LVWO RECYCLING ENERGY TECHNOLOGY CO LTD

an hvac system

ActiveCN105024593BAvoid redevelopmentReduce R&D costsSingle motor speed/torque controlLow voltageAlternating current

The invention discloses an HVAC system. The HVAC system originally used a PSC fan motor, including an HVAC system controller, and now replaces the PSC fan motor with an ECM motor, wherein: the HVAC system controller has several 115V motors connected to the motor. Or a 230V AC output port and a common port, the ECM motor is provided with several 24V low-voltage AC gear input lines, and the ECM selects the operating parameters of the motor according to the selected gear input lines in the conduction state; it also It includes an intermediate connection device, which is connected between the HVAC system controller and the ECM motor, and the intermediate connection device converts the 115V or 230V AC signals of several output ports of the HVAC system controller into several The 24V low-voltage AC signal identified by the gear position input line avoids redevelopment, reduces R&D costs and shortens the R&D cycle, reduces product models, and facilitates management.

Owner:ZHONGSHAN BROAD OCEAN

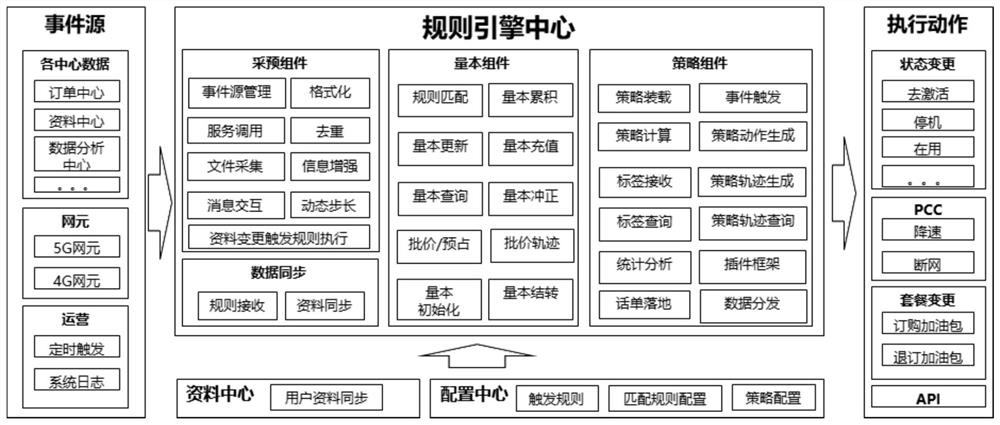

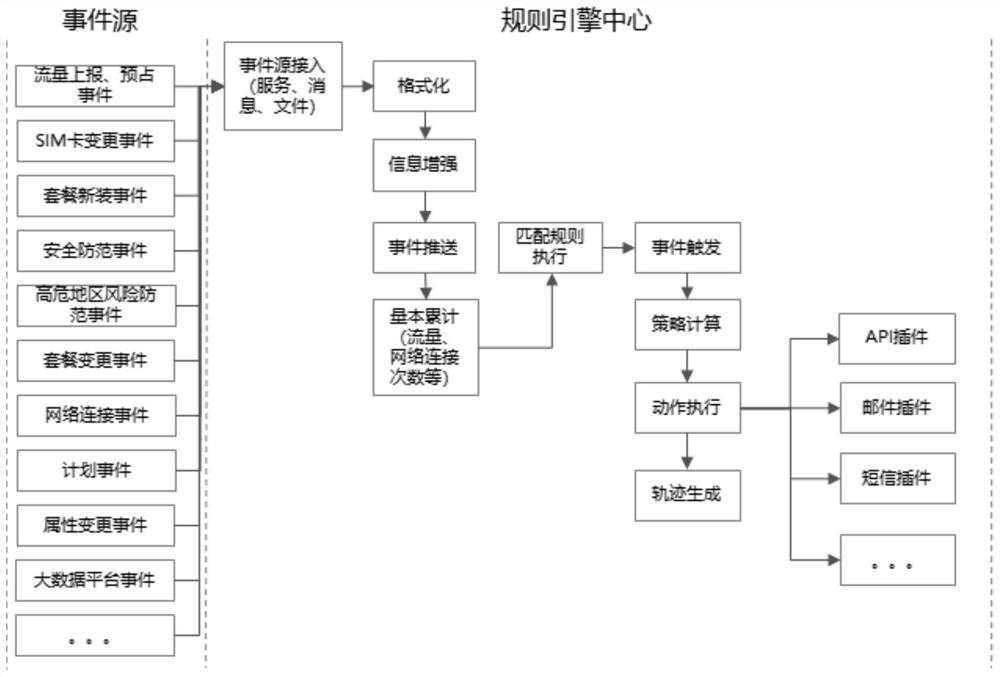

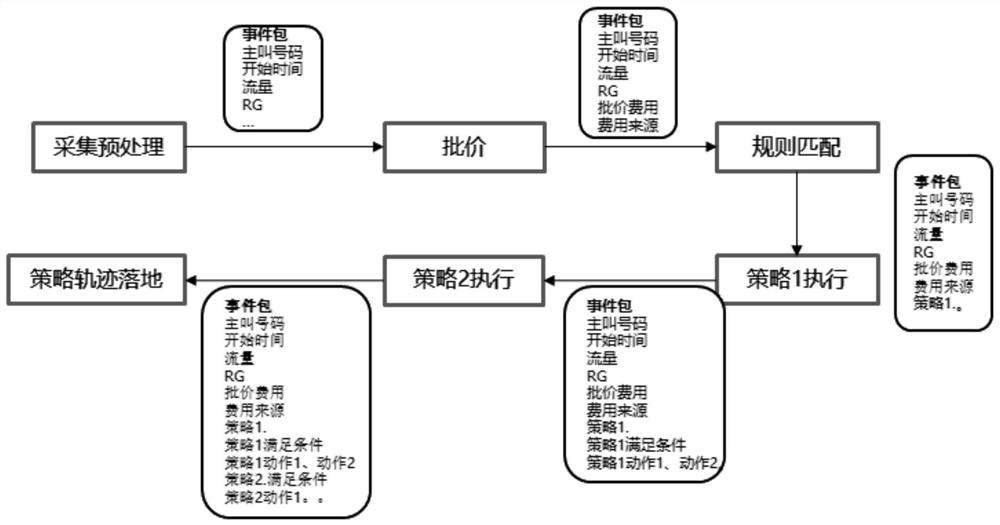

Real-time charging control method and system based on rule engine

PendingCN114037432AAchieve decouplingAvoid redevelopmentPayment architectureOffice automationTechnology developmentBusiness rule

The invention discloses a real-time charging control method based on a rule engine, relates to software technology development, and solves the technical problem of low system stability due to strong coupling between a service rule and a service system. The method comprises the following steps: collecting a source event, synchronously integrating business rules of all rules, and carrying out matching processing on the source event according to a user matching rule in the business rules to obtain an event packet; and triggering a policy rule in the service rule corresponding to the event packet, performing policy analysis on the event packet according to the policy rule, and triggering a charging execution action. The invention further discloses a real-time charging control system based on the rule engine. According to the invention, decoupling of the business rules and the business system is realized, the stability and flexibility of the system are improved, and the problem that the system needs to be redeveloped due to change of the business rules is avoided.

Owner:GUANGDONG ESHORE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com