Stamping type stepped bonding pad PCB and manufacturing technology

A manufacturing technology, stamping technology, applied in the direction of printed circuit manufacturing, the formation of electrical connection of printed components, and the electrical connection of printed components, etc., can solve problems such as difficult to solve problems, project schedule, cost impact, etc., and achieve the effect of making up for insufficient height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

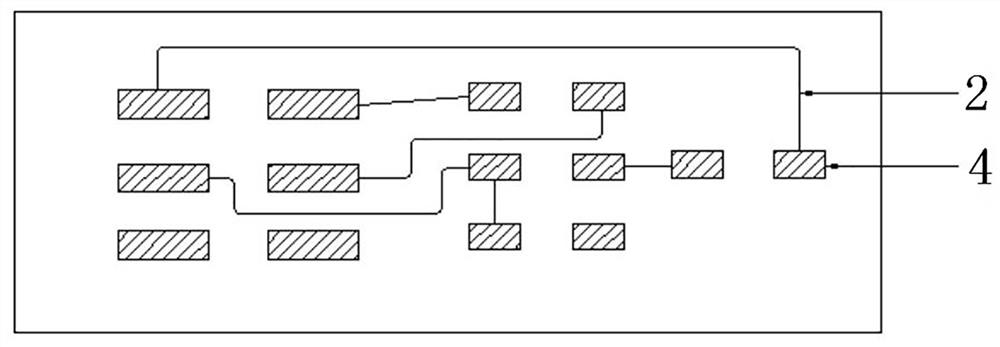

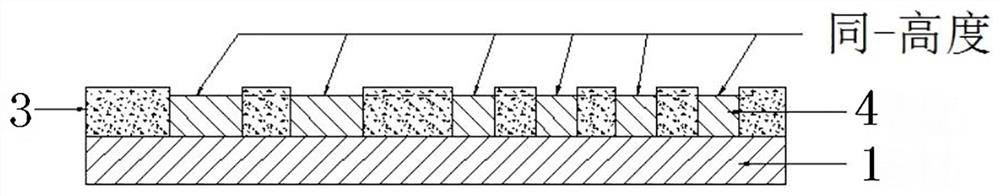

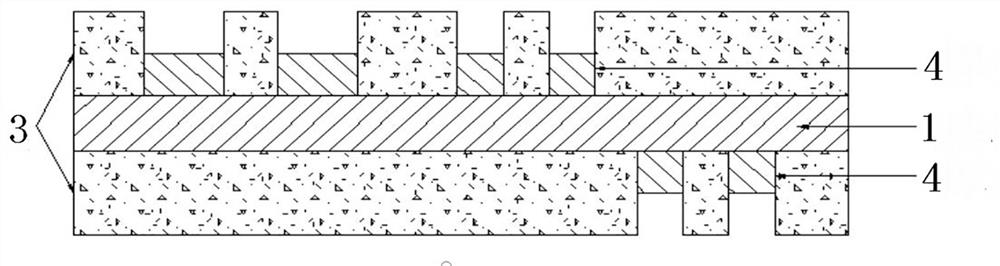

[0023] Such as image 3 with Figure 4 said, image 3 It is a simple schematic diagram of a double-sided semi-finished product, in which only the substrate, pads and cover film are shown. The double-sided board can be made according to the conventional method. In order to increase the operability, the finished PCB die-cuts the shape and cannot be cut into single pieces. In this embodiment, the present invention includes a PCB substrate 1, which is arranged on the PCB The circuit 2 on the circuit 1 and the solder resist ink or cover film 3 covering the circuit 2, the stamped stepped pad PCB also includes a circuit that is electrically connected to the circuit 2 and is not covered by the solder resist ink or the A plurality of pads 4 covered by the cover film 3, at least one of the pads 4 is a stamped stepped pad, and a stamped boss 5 is arranged on the top of the stamped stepped pad, and the bottom of the stamped stepped pad A concave cavity 6 corresponding to the stamping b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com