High-efficiency micro-conduction heat dissipation module

A heat dissipation module and micro-guide technology, which is applied in the direction of cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc., can solve the problems of large heat and cannot meet the requirements of heat dissipation, and meet the weight requirements, Lightweight and compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

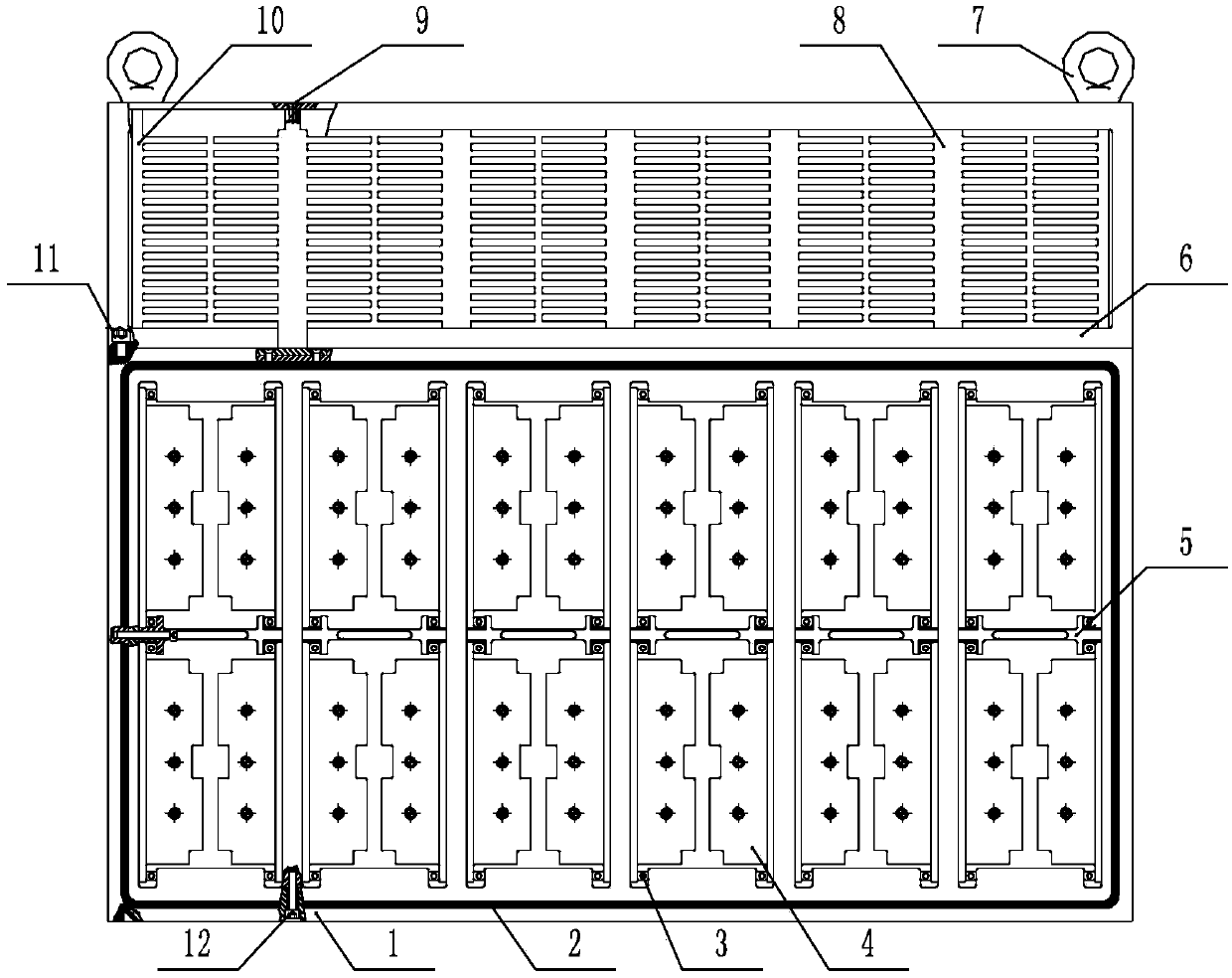

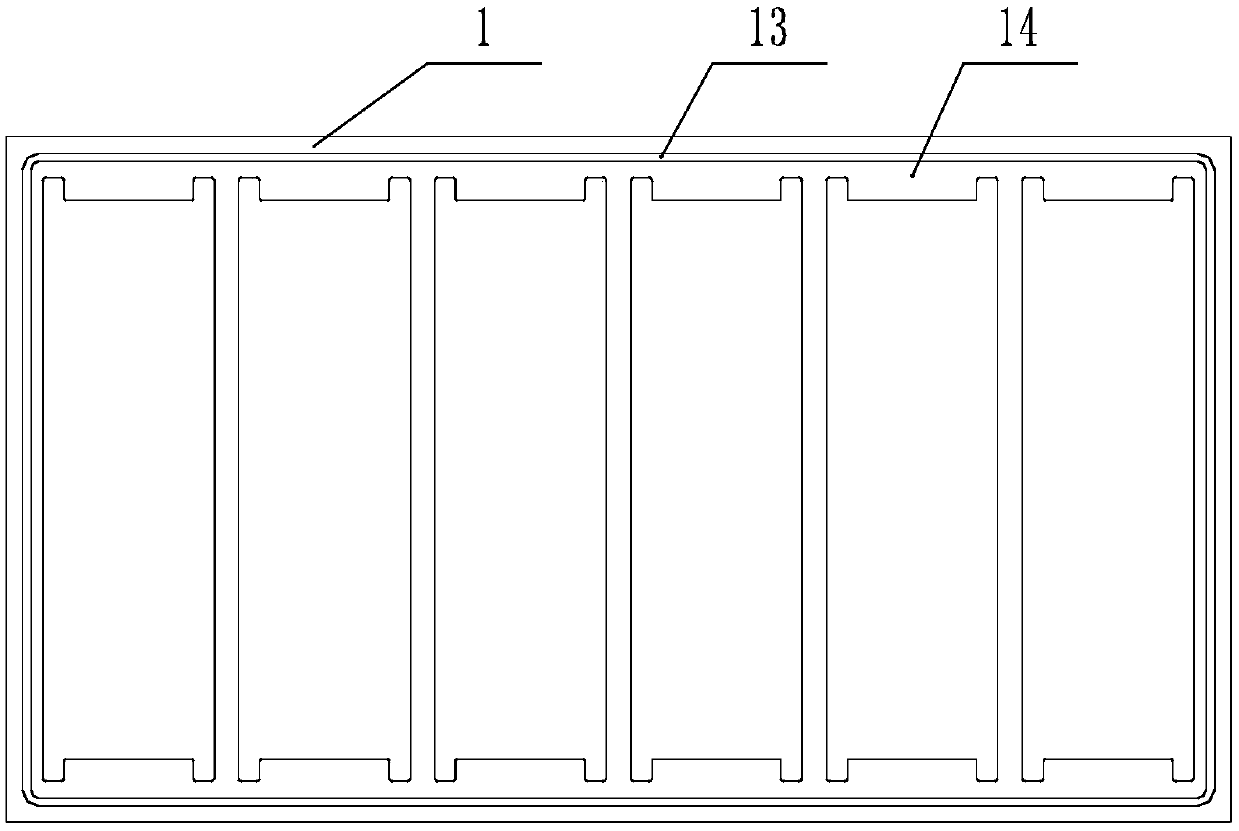

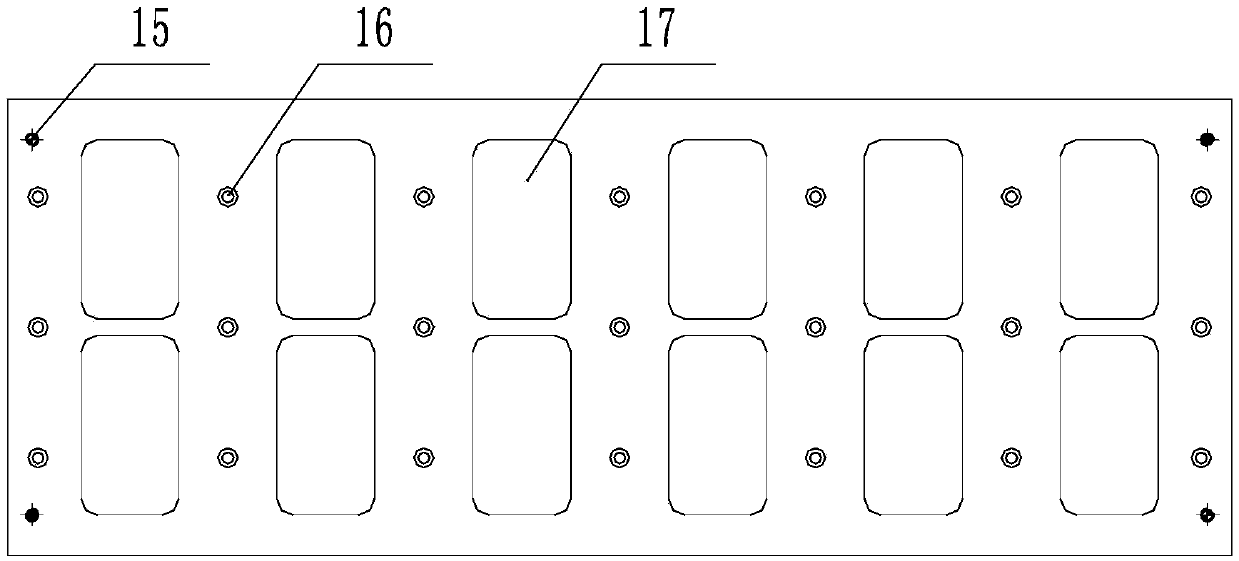

[0061] See Figure 1-Figure 22 , When installing, the number of high-efficiency micro-conducting heat sinks I8 is 4 pieces, and the number of high-efficiency micro-conducting heat sinks II10 is 2 pieces, arranged according to the positions shown in the figure. The intelligent power module 4, as shown in the figure, is fixed on the heat-absorbing surface 33 of the high-efficiency micro-conduction heat sink I8 and the high-efficiency micro-conduction heat sink II10 with the fixed pressure rod 3; the high-efficiency micro-conduction heat sink I8 and the high-efficiency micro-conduction The radiator II10 is an integrated structure of the same material, and there is no contact thermal resistance during the heat transfer process; the heat-absorbing surface 33 is inserted into the lower cabinet of the module through the installation through groove I22 and the installation through groove II23 on the top of the module lower cabinet body 1 1 Inside the closed cavity; the guide rail groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com