Rolled h-beam steel and production method therefor

A manufacturing method, H-shaped steel technology, applied in the direction of manufacturing tools, metal rolling, metal rolling, etc., can solve problems such as bad influence of toughness, and achieve significant contribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

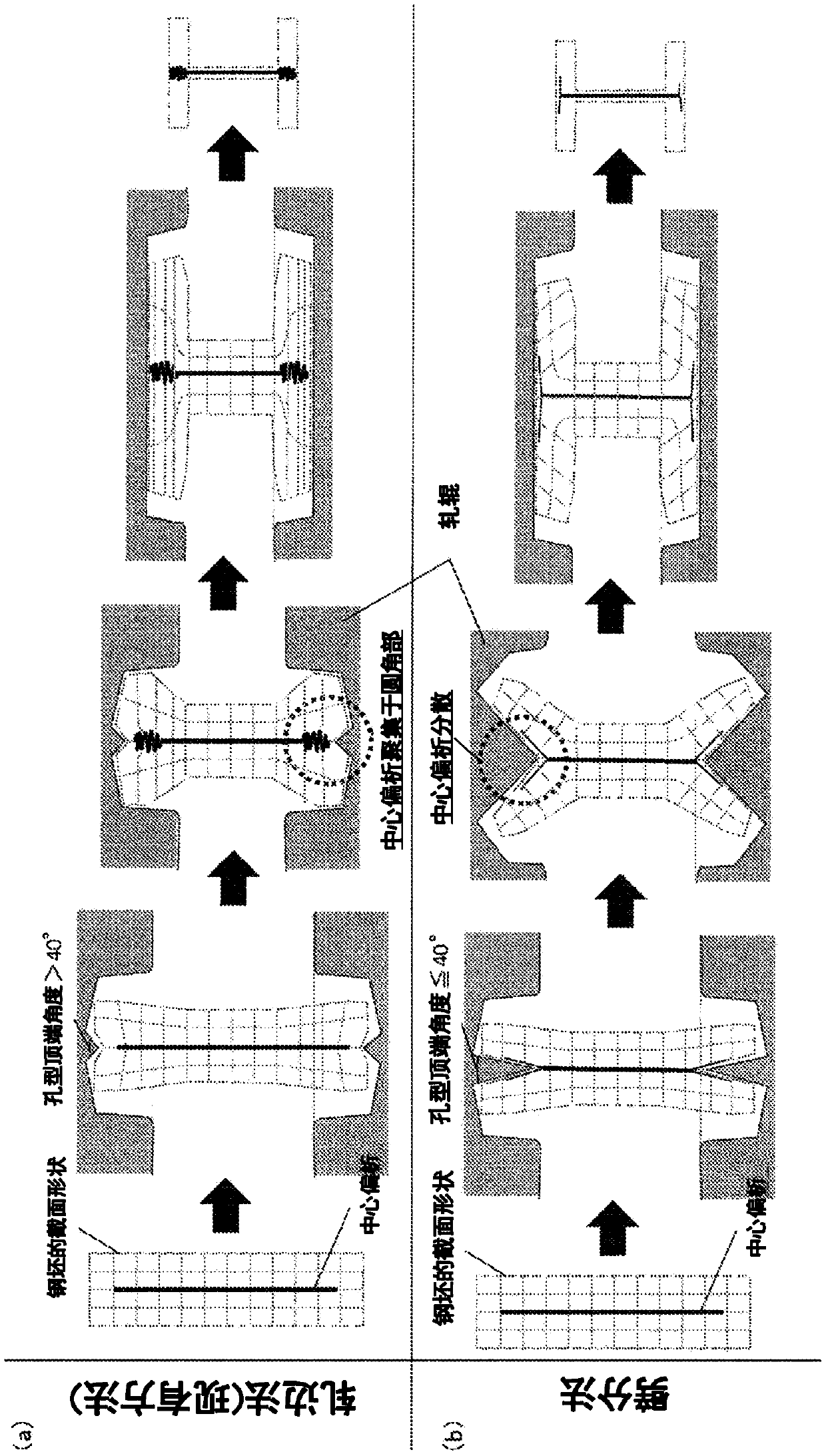

Method used

Image

Examples

Embodiment

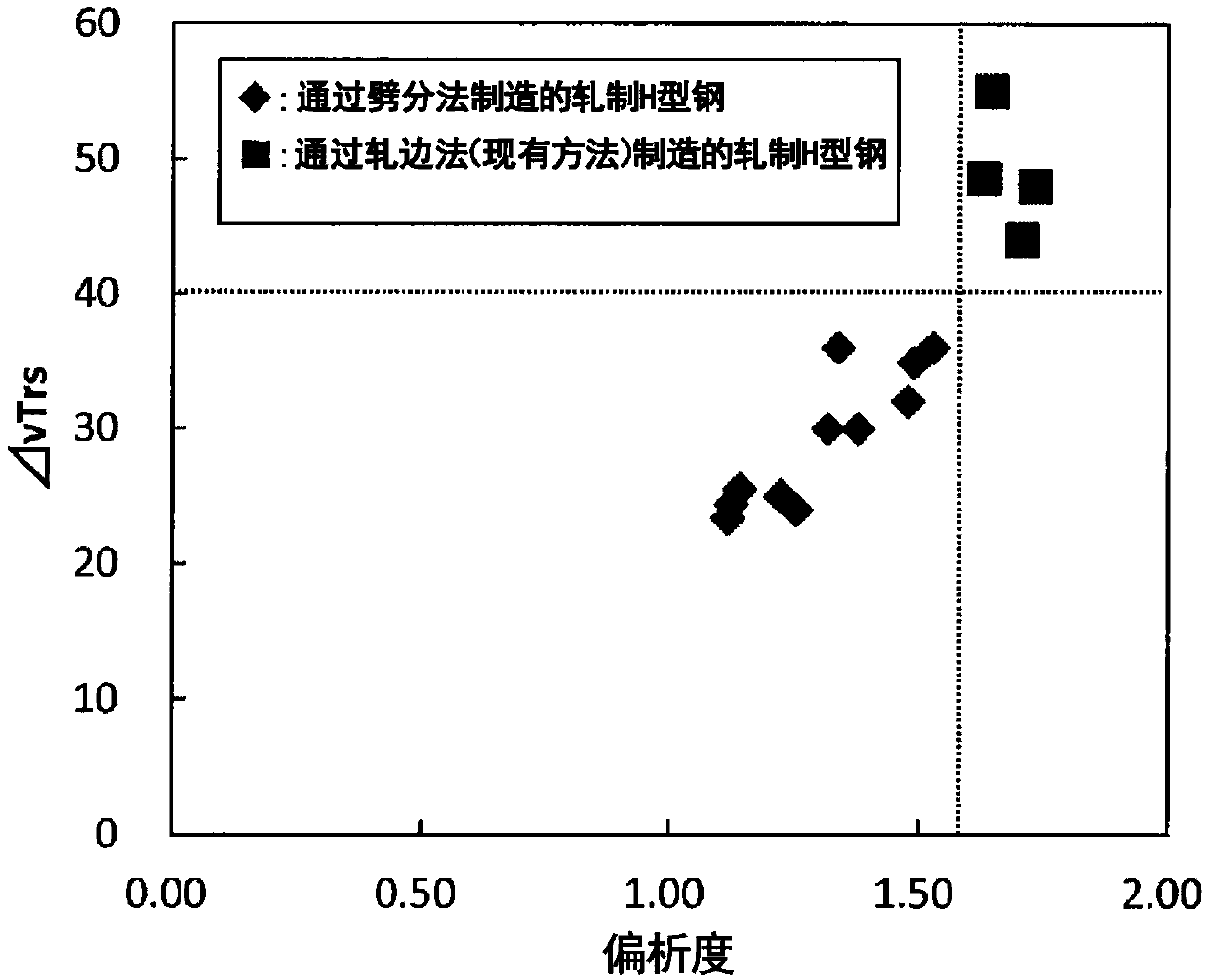

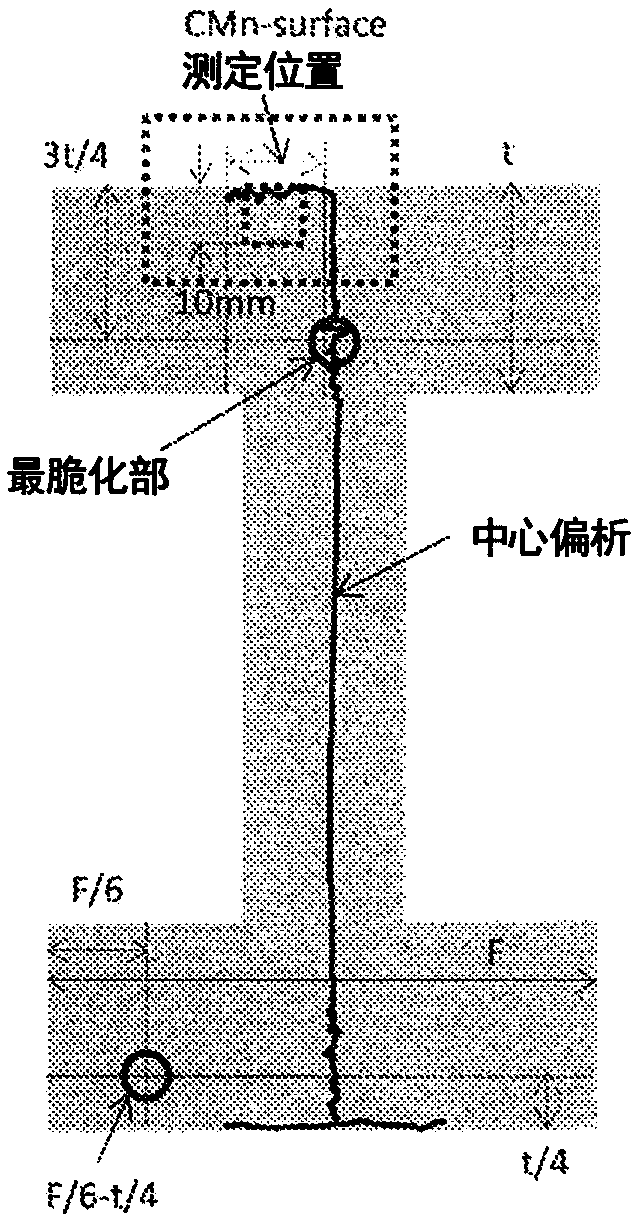

[0129] As an example of the present invention, a sample was cut out from a rolled H-section steel manufactured to satisfy the composition and manufacturing conditions described in the above embodiments, and the sample was subjected to chemical analysis. On the other hand, as a comparative example, a sample was cut out from a rolled H-section steel that did not satisfy any of the composition and manufacturing conditions described in the above embodiment, and the same chemical analysis was performed. Hereinafter, comparison of detailed examples and comparative examples will be described.

[0130] (Example)

[0131] First, as Examples Nos. 1 to 13 and 28, steels having the composition (unit: mass %) shown in Table 1 were melted, and steel slabs with a thickness of 250 to 300 mm were produced by continuous casting. Steel is smelted in a converter, deoxidized once, alloys are added to adjust the composition, and vacuum degassing is performed as needed. Then, the obtained slabs we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com