Forging die set and forging method of large-scale thin-wall barrel type flange plate

A complete set of molds and thin-walled technology, applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve problems such as material waste, reduce material waste, improve production efficiency, and save materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

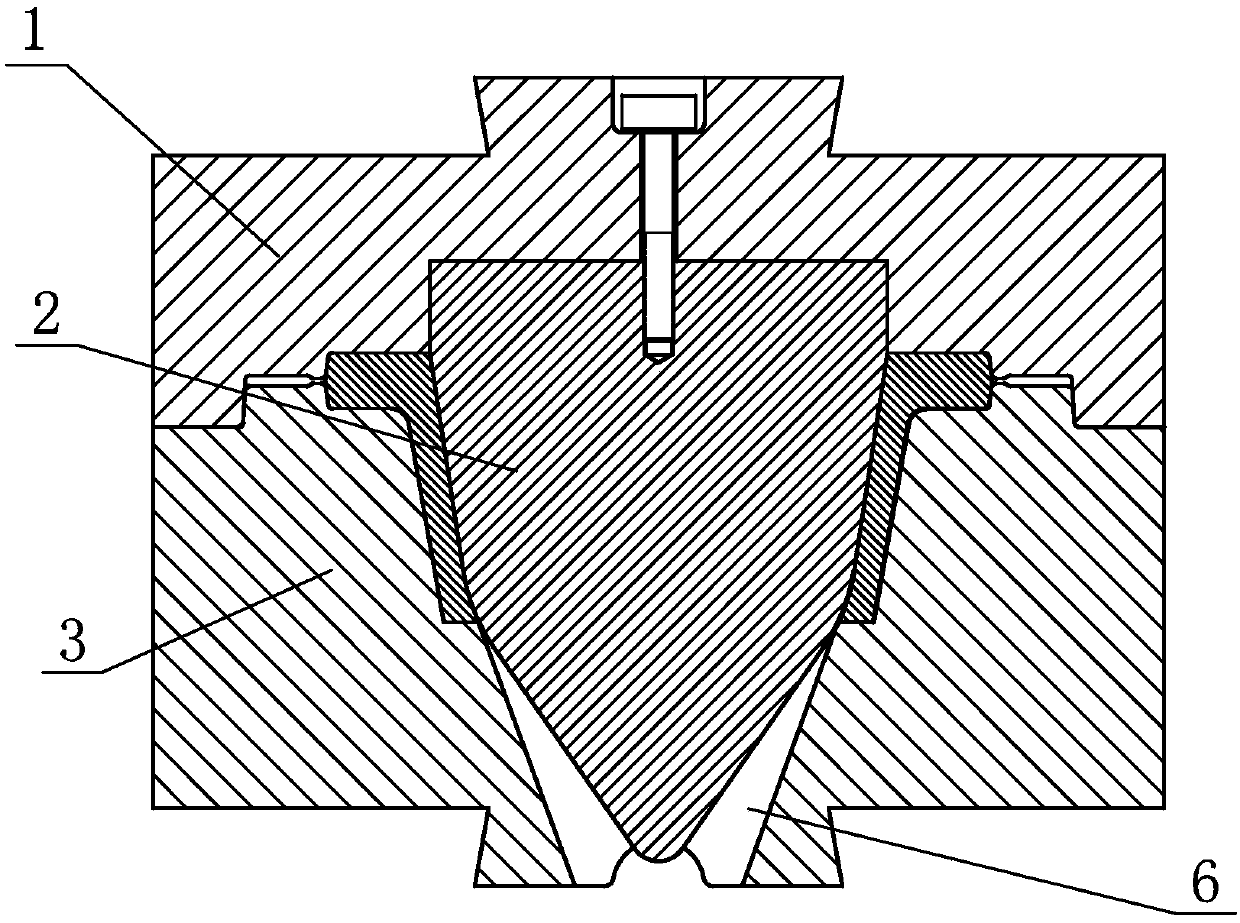

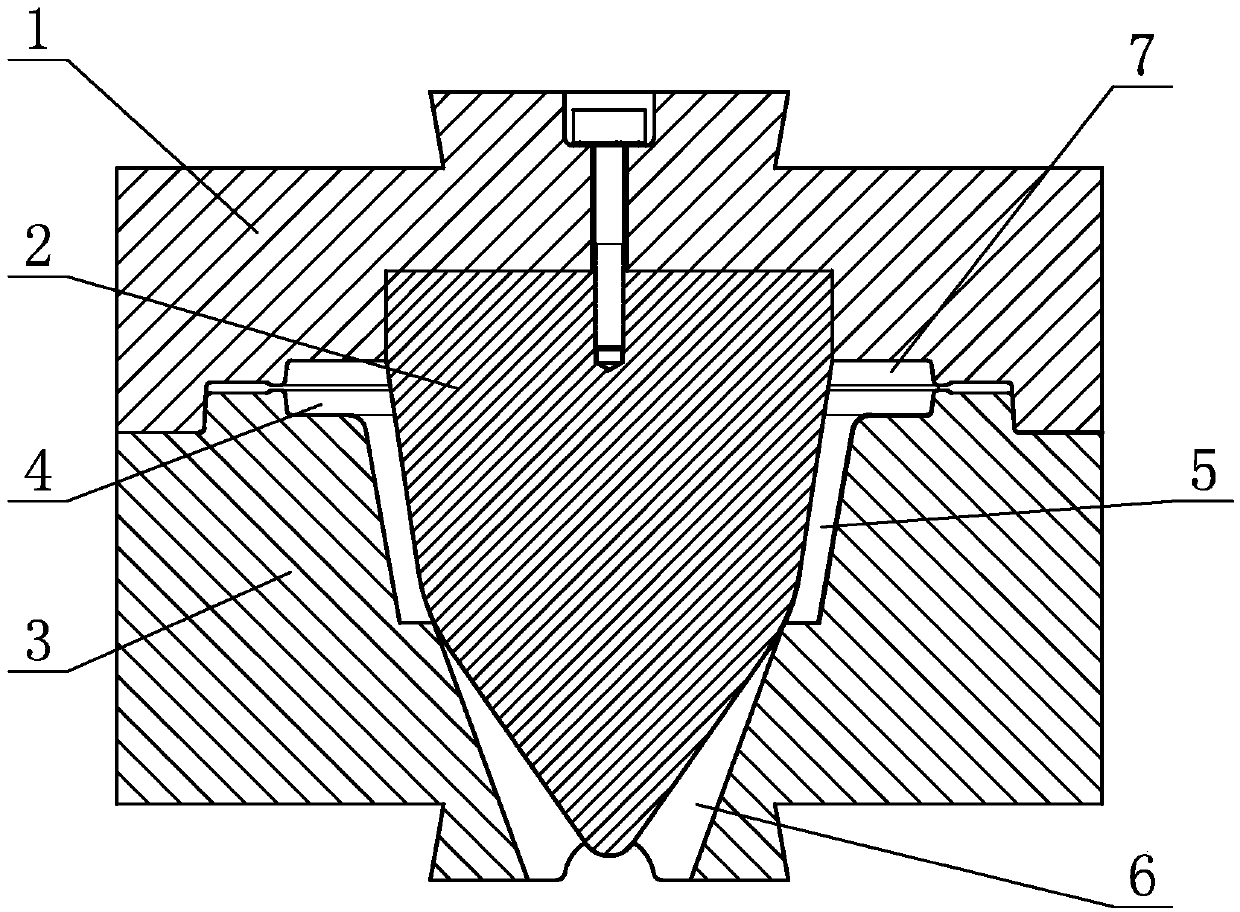

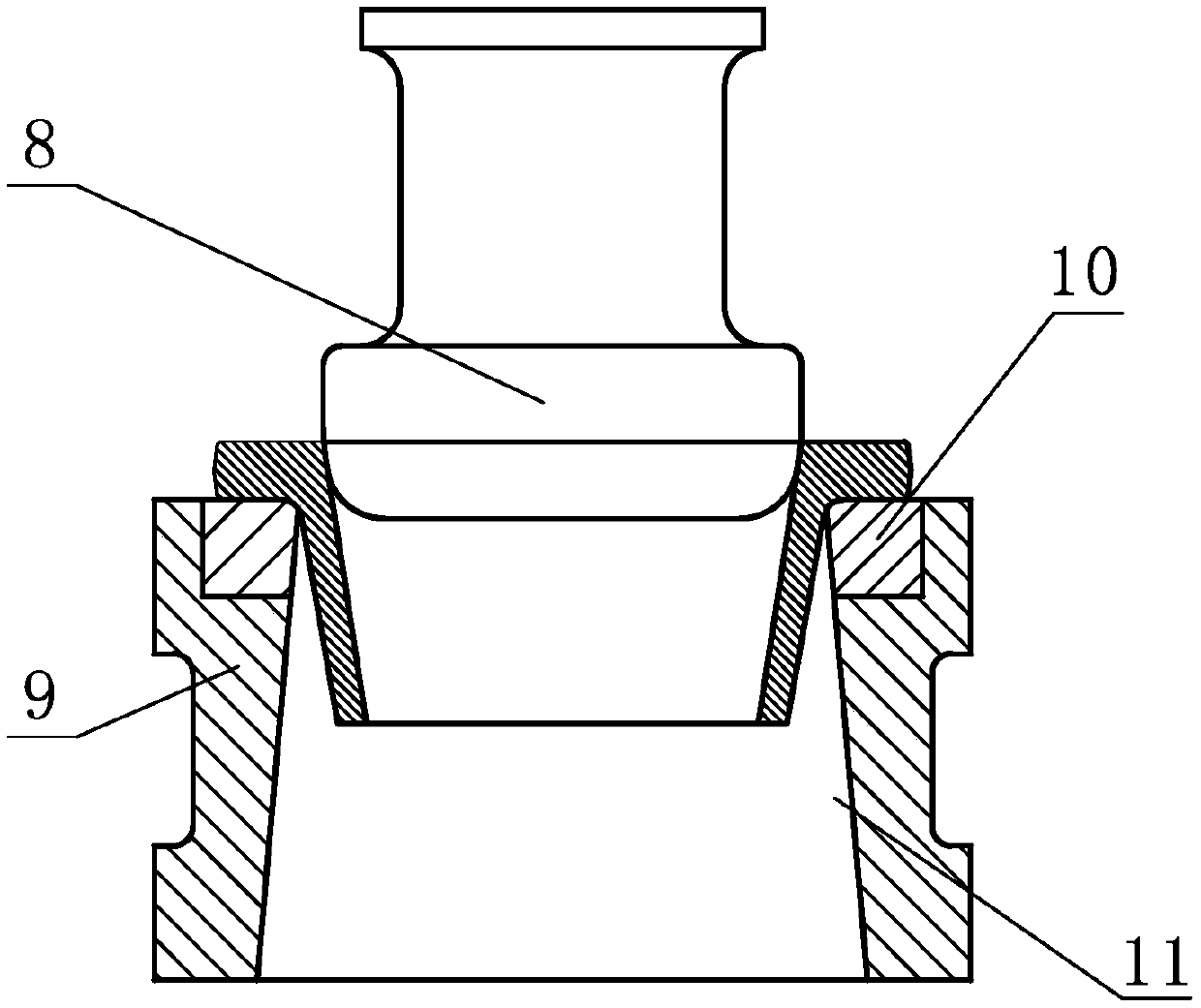

[0030] Such as Figure 1 to Figure 3 As shown, a complete set of forging dies for a large thin-walled cylindrical flange includes a shaping die and a forging die for blank preforming; the forging die includes an upper die 1 and a lower die 3, and the upper die 1 and the lower die 3 Form the cavity of the preform; the upper mold 1 is provided with a punch 2 for forming an inner hole on the preform; the cavity includes a first cavity 4 and a second cavity 5 formed on the lower mold 3 , the second cavity 5 is used to form the cylindrical part of the preform, and the lower end of the lower mold 3 is also provided with a first through hole 6 connected with the second cavity 5, and the first through hole 6 constitutes the center of the punch 2 avoidance space; the upper mold 1 is provided with a third cavity 7, and the third cavity 7 and the first cavity 4 jointly form the flange part of the preform; the second cavity 5 and the punch 2 are both It has a draft angle; the shaping die...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com