Method for making polyurethane shoe pad with ventilation holes

A technology of polyurethane and manufacturing methods, which can be used in insoles, footwear, clothing, etc., and can solve problems such as incomplete hole patterns and rough scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

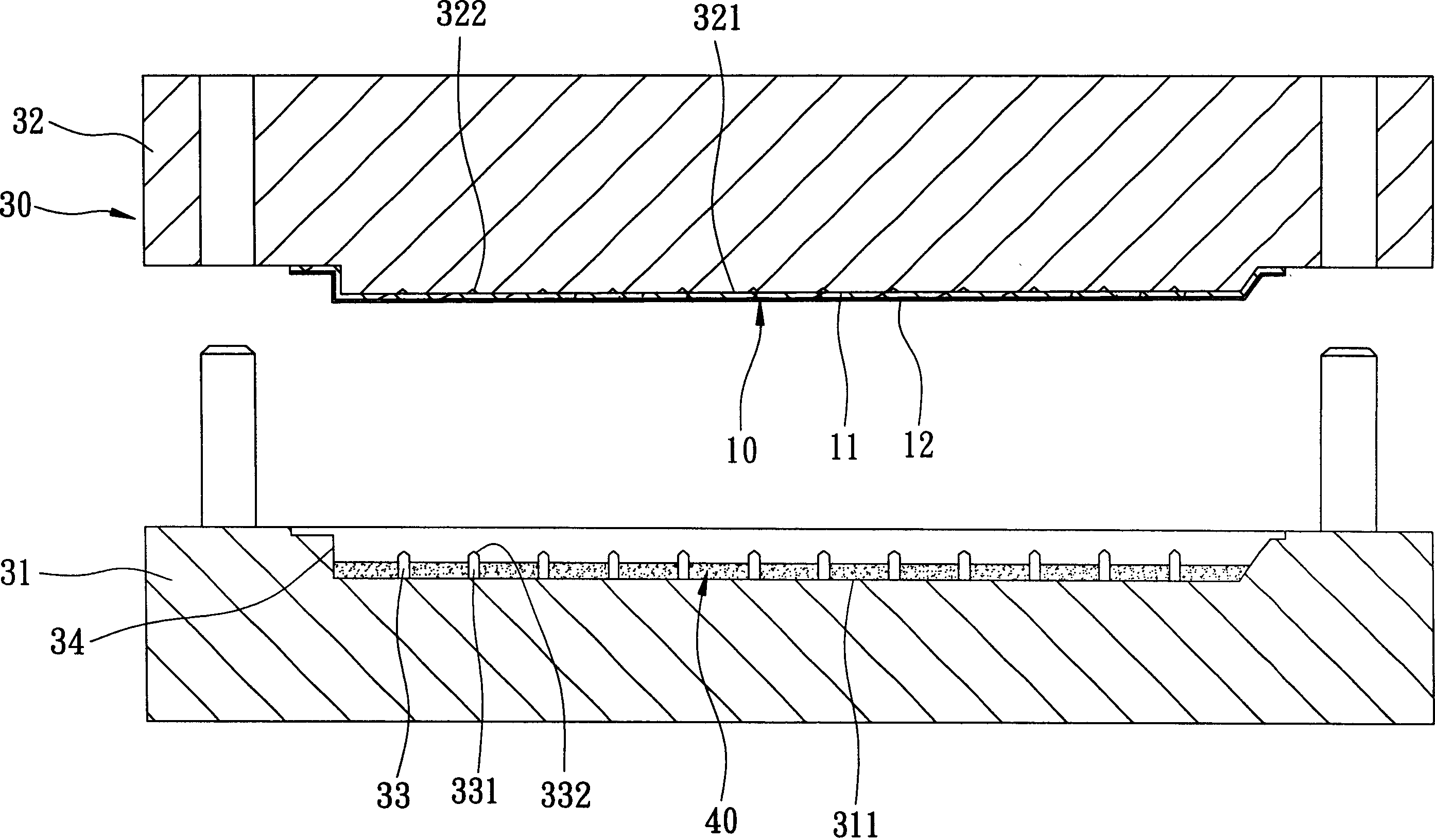

[0029] For convenience of description, in the following embodiments, the same components are denoted by the same reference numerals.

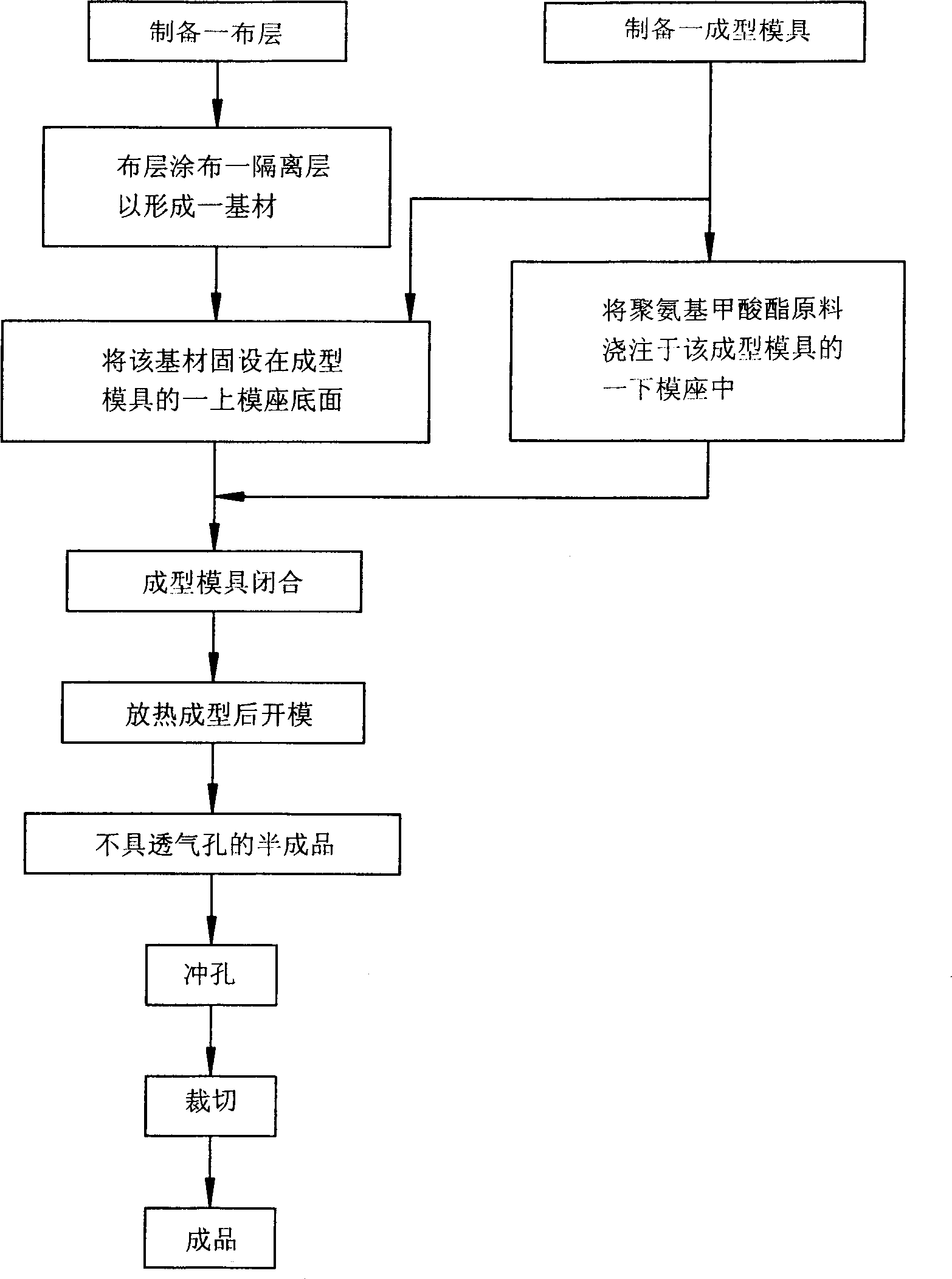

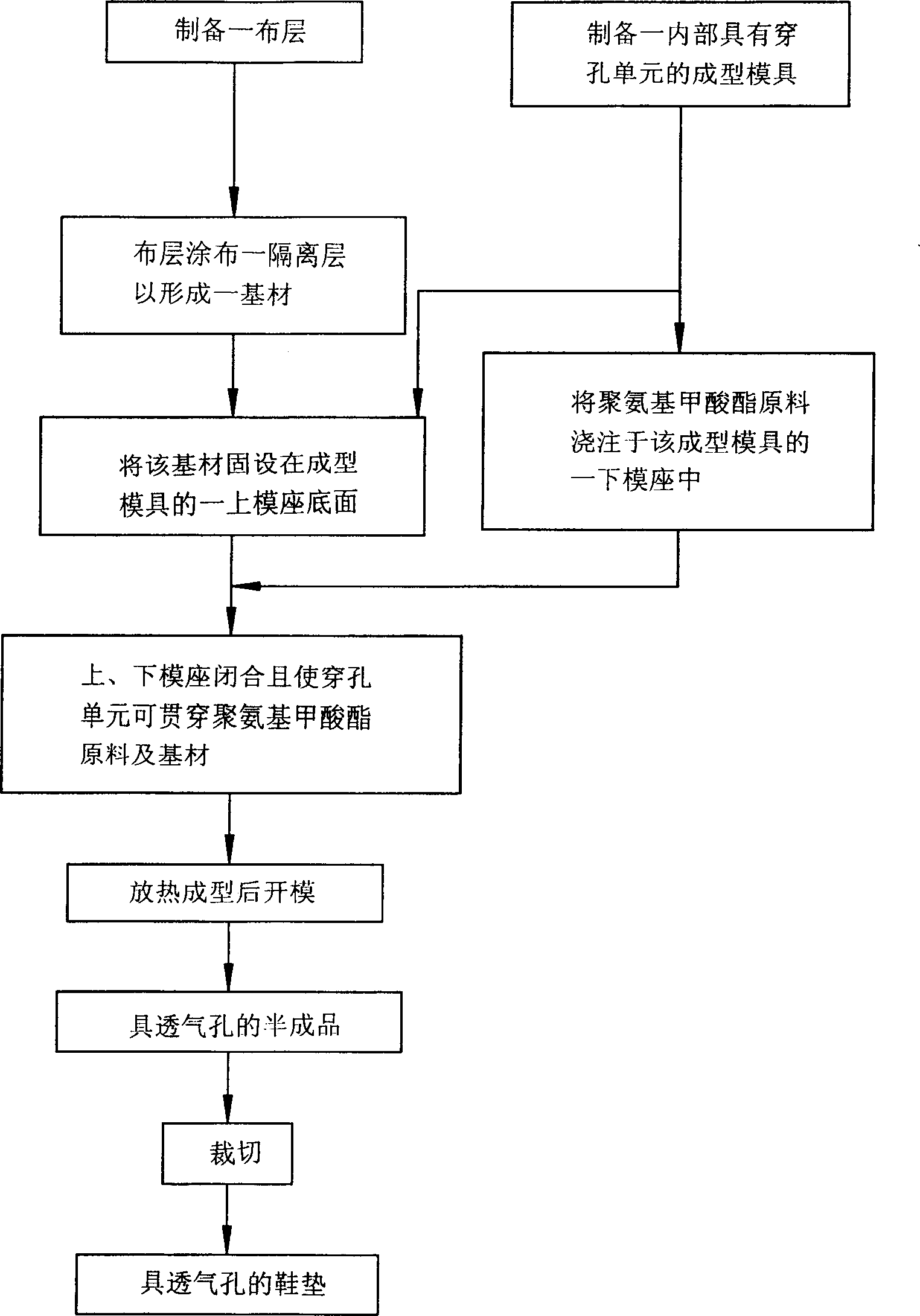

[0030] like figure 2 , image 3 Shown, the first preferred embodiment of the manufacture method of the polyurethane insole with air vent of the present invention is suitable for making the polyurethane insole with the air vent of smaller aperture, and comprises the following steps:

[0031] Step 1: Prepare a cloth layer 11 and a forming mold 30 . The cloth layer 11 can be terry cloth, non-woven fabric, braided fabric. The molding die 30 of the present embodiment has a lower mold base 31, an upper mold base 32 that can be closed or separated from the lower mold base 31 and a perforation unit 33 connected to the lower mold base 31, and the lower, A mold cavity 34 can be formed when the upper mold bases 31, 32 are closed relative to each other. The perforating unit 33 has a plurality of perforating needles 331. The bottom surface 311 of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com