Gear case gear shaft pin head laser welding feeding and discharging device

A laser welding and gear shaft technology, applied in the field of mechanical transmission, can solve the problems of difficult to ensure product quality, weak welding, loss of workpiece cost, etc., to achieve the effect of improving welding quality and welding efficiency, and preventing unstable installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the present invention more obvious and understandable, the detailed description is as follows in conjunction with the accompanying drawings.

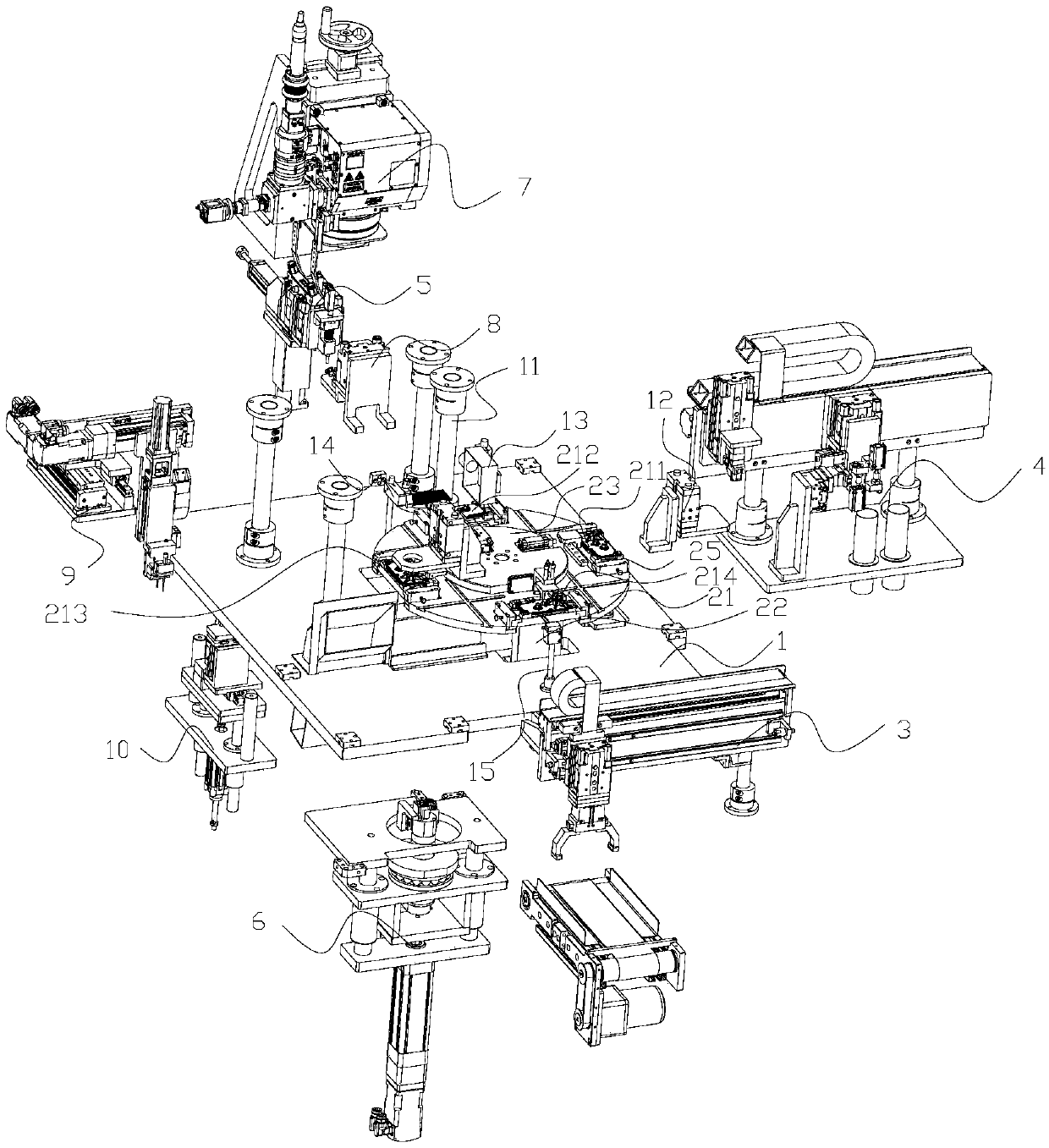

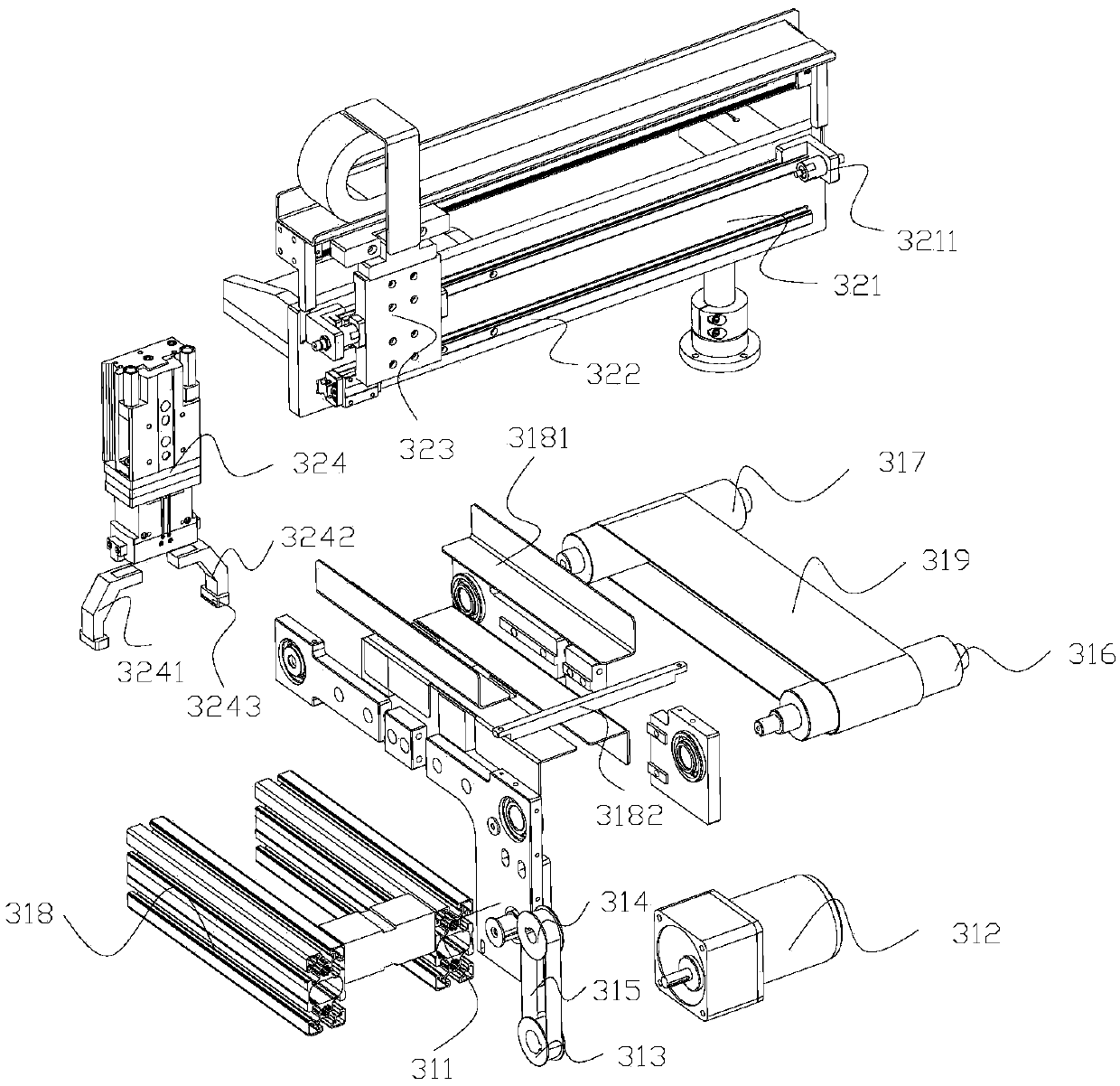

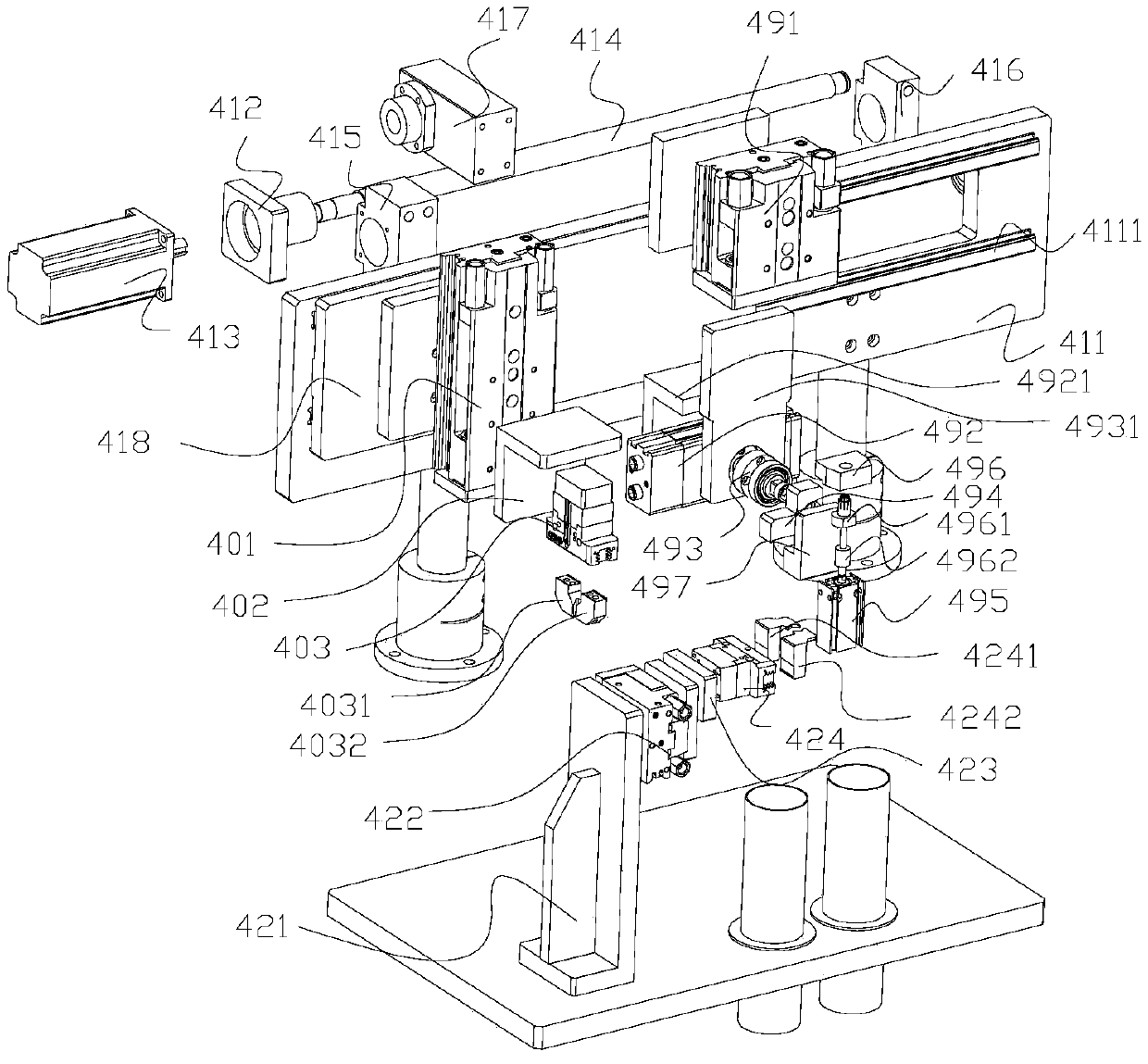

[0032] Such as figure 1 with Figure 11As shown, a gearbox gear shaft laser welding detection equipment, the equipment includes a frame 1, an indexing device, a cover plate loading and unloading device 3, a pin head loading and unloading device 4, an axial gap closed-loop device 5, an axial gap Adjusting device 6 , laser welding device 7 , pin head pressing device 8 , eddy current testing device 9 and axial clearance testing device 10 . The indexing plate device includes an indexing plate 21 , an indexing plate drive module 22 and a fixed plate 23 . The index plate drive module 22 is fixedly arranged on the frame 1, the fixed plate 23 is connected with the index plate drive module 22 through the intermediate transition plate, and the index plate 21 is located at the index plate drive module 22 And between the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap