Flexible automatic device for assembling notebook computer rear cover screws and gaskets

A notebook and gasket technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of increasing product production time, small shape of screws and gaskets, and long pick and place time, and achieve considerable economic effects, The effect of improving yield and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

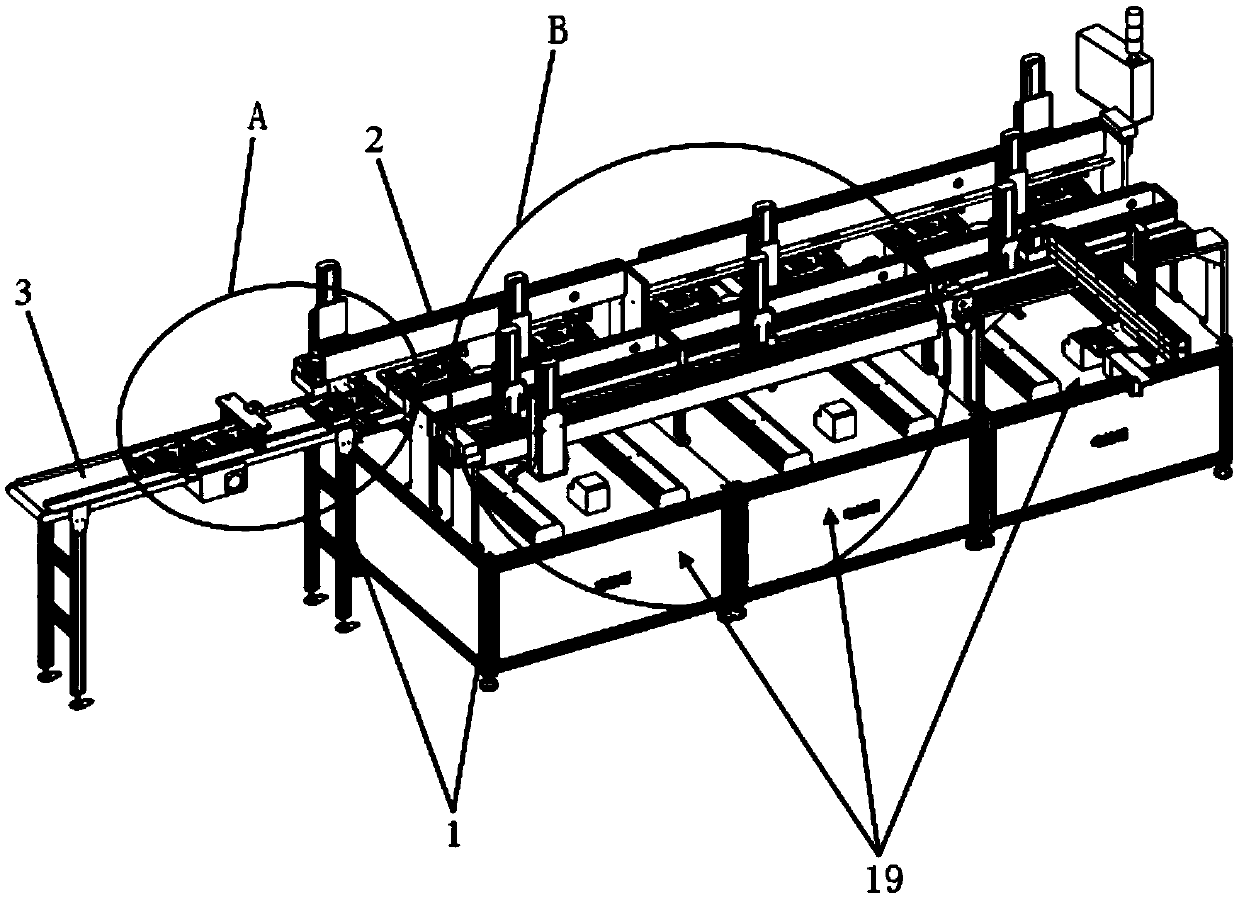

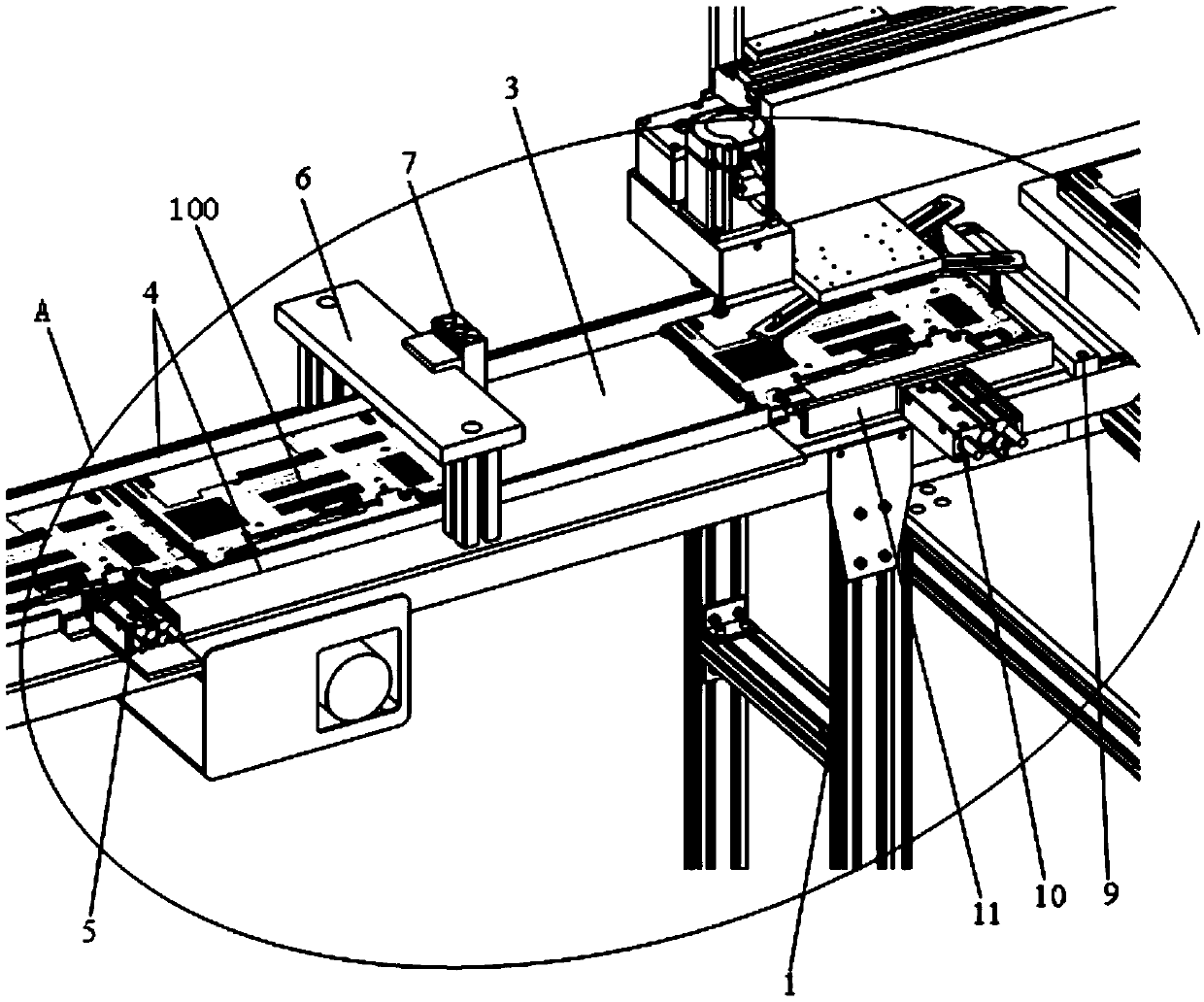

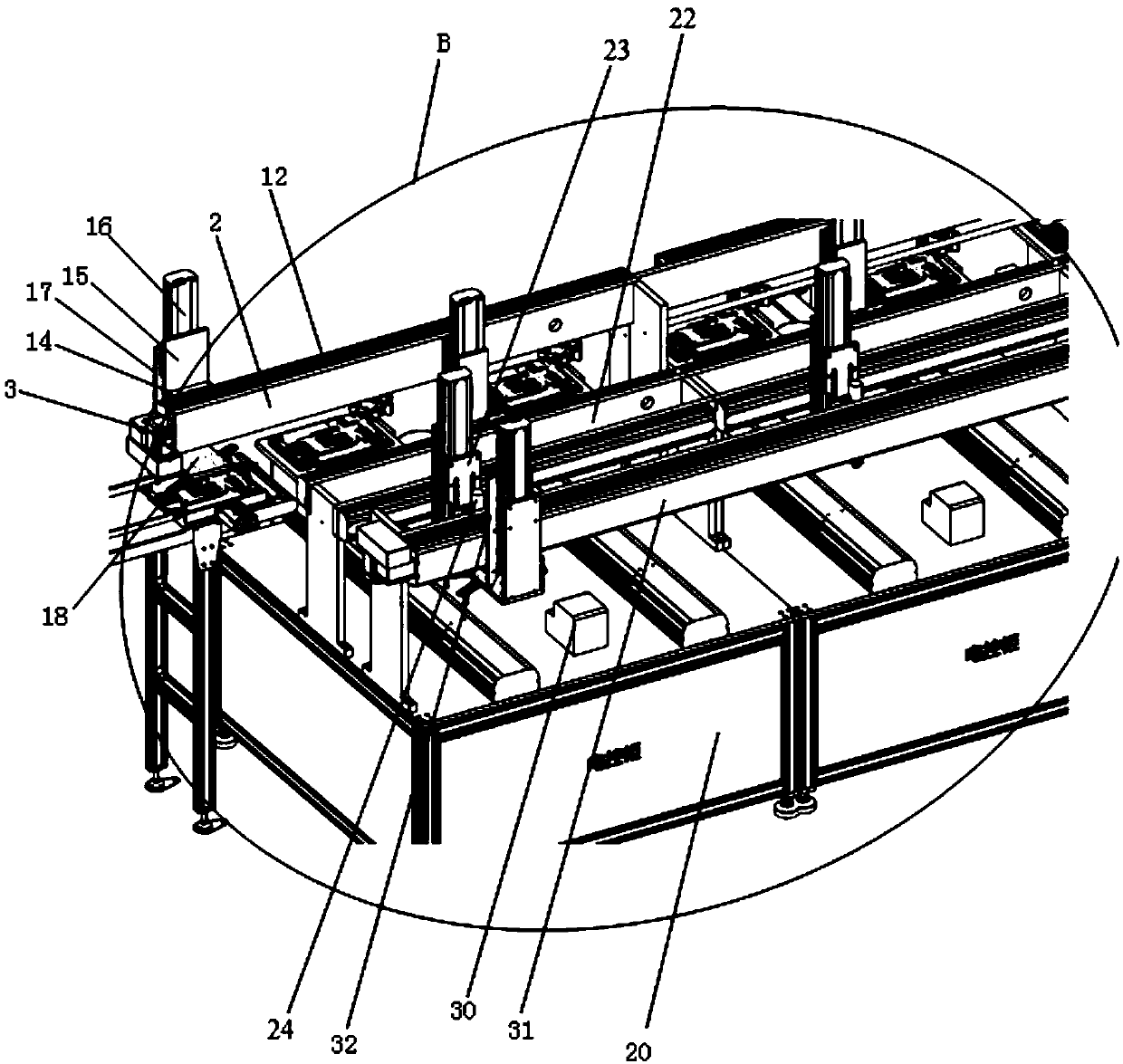

[0019] See attached Figure 1-Figure 10 As shown, a flexible automation equipment for assembling the screws and gaskets of the back cover of the notebook, including a frame 1, a shell transmission system and a first X-axis beam 2 arranged on the frame 1, the shell transmission system Be belt line 3, be provided with guardrail 4 on the side of described belt line 3, be provided with distributing mechanism and positioning mechanism on described belt line 3, described material distributing mechanism comprises the first that is located at described belt line 3 side A sensor 5 and a first support 6 arranged at the upper end of the belt line 3 , the first air cylinder 7 is installed on the first support 6 , and the first retaining bar 8 is connected to the first air cylinder 7 . Described positioning mechanism comprises positioning block 9 and second air cylinder 10, and described positioning block 9 is installed on the end of described belt line 3, and described second air cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com