Roller type synchronous locking device

A locking device, roller-type technology, applied in the direction of hand-held tools, manufacturing tools, etc., can solve the problems of restricting the assembly reliability of components, failing to meet assembly requirements, and difficult to control the locking state, so as to achieve simple and labor-saving connecting rod structure, Strong practicability and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

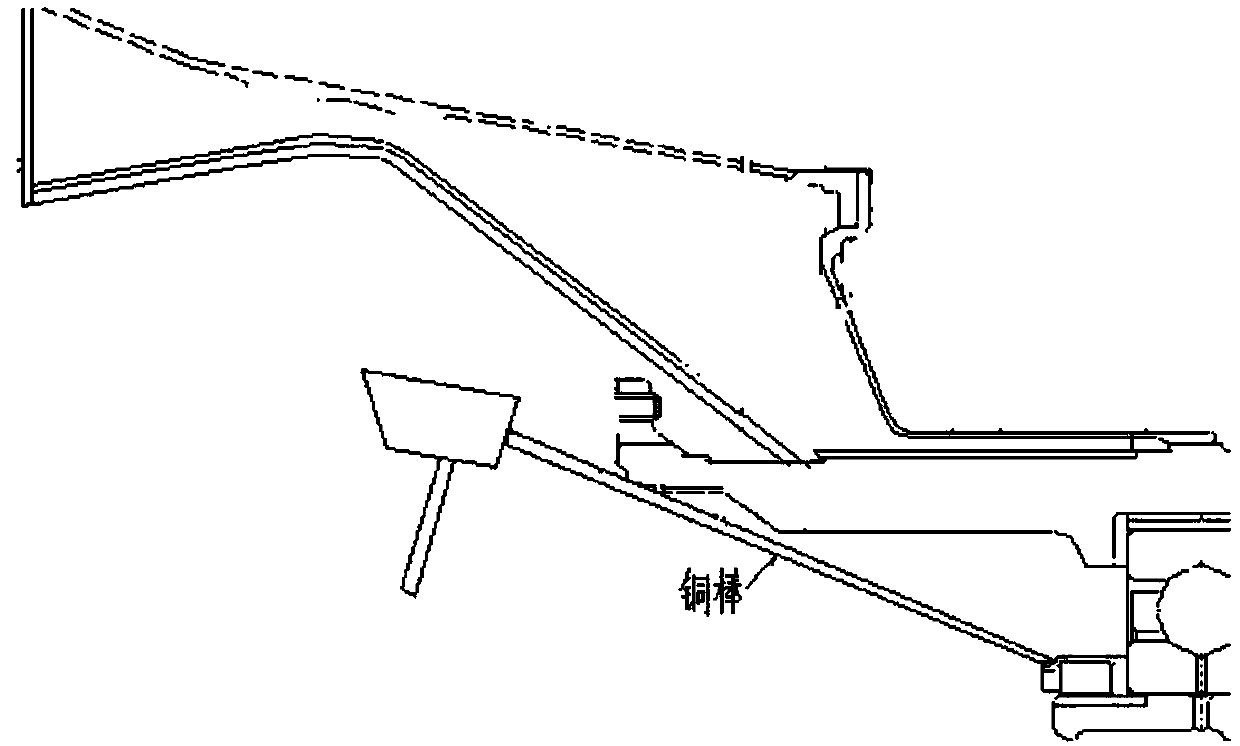

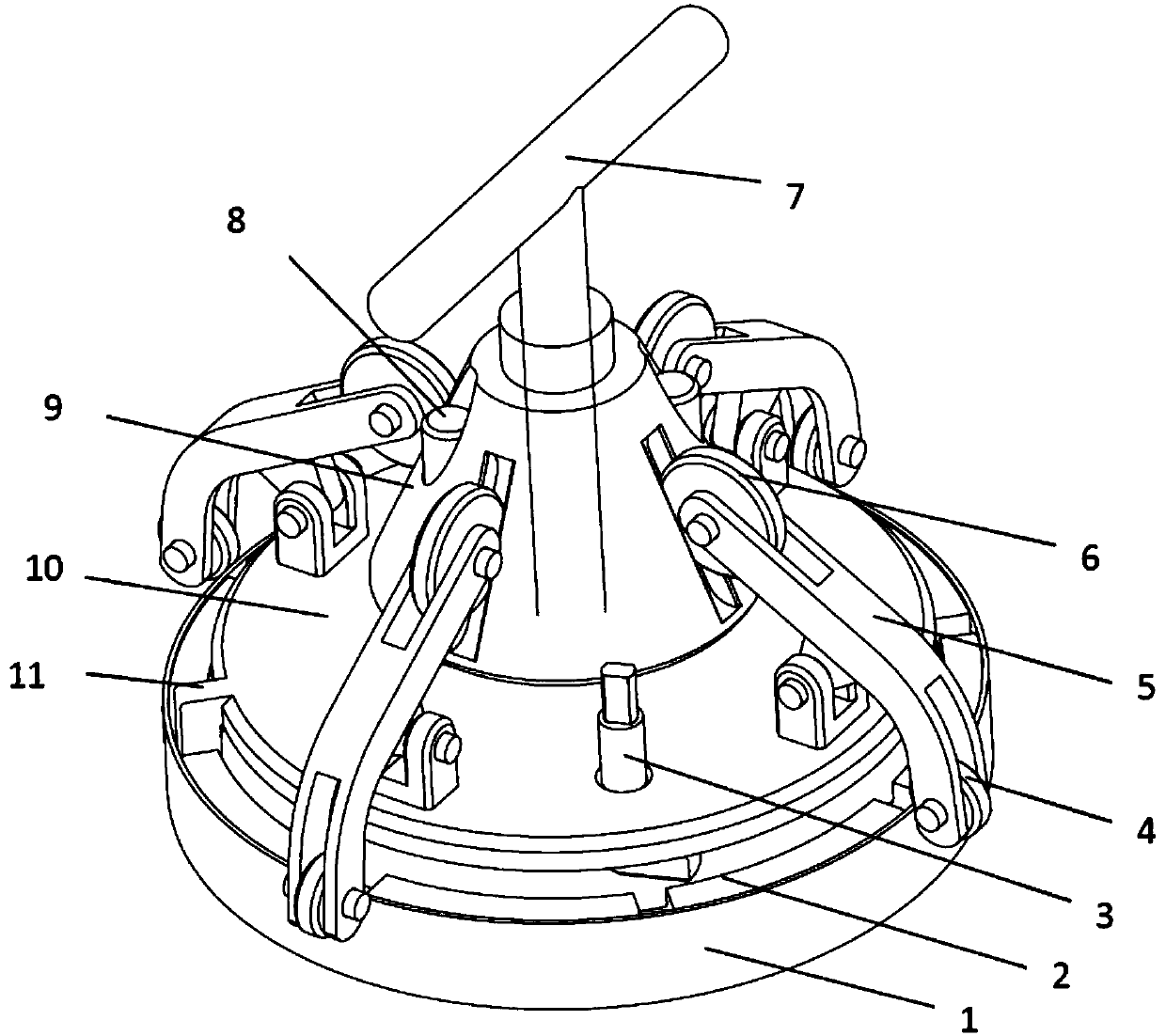

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings of the description, please refer to figure 2 .

[0017] figure 2 A four-point synchronous roller locking device according to an embodiment of the present invention is shown, and the four-point synchronous roller locking device includes four linkage mechanisms formed by a pressure wheel 4, a connecting rod 5, and a roller 6, a sliding rod 8, and a top plate 10 , The positioning tooth 11 is an integrated top plate structure, the top tool 9 and the ejector rod.

[0018] After the rotation angle of the pressing cam 3, fix the device on the journal to prevent the device from falling off; the positioning teeth 11 in the top plate structure snap into the groove of the shaft end nut 2 to determine the locking position of the lock cup ; The push rod 7 props up on the top plate 10 and spirally moves; the described top tool 9 slides upwards along the slide bar 8, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com