Discharger impeller blade

A technology of impeller blades and fan shut-off, which is applied in the direction of conveyors, transportation and packaging, and conveying bulk materials. Stuck, increase the gap, prevent the effect of impeller blade jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

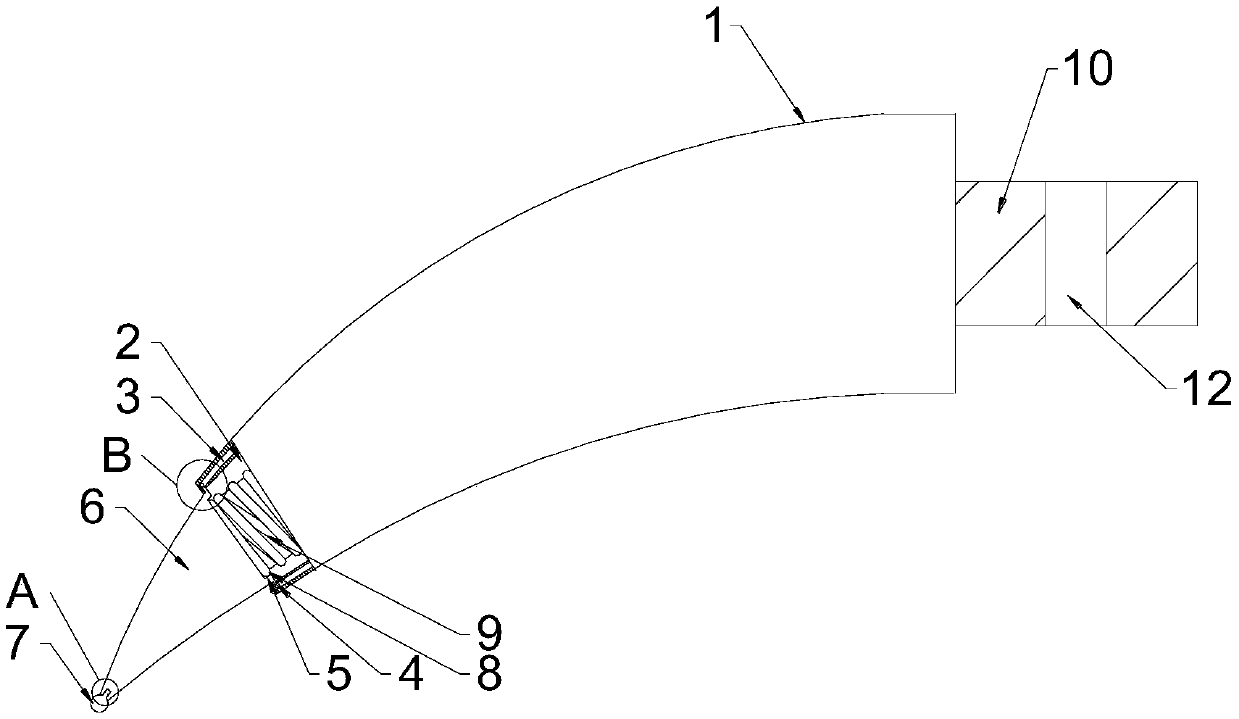

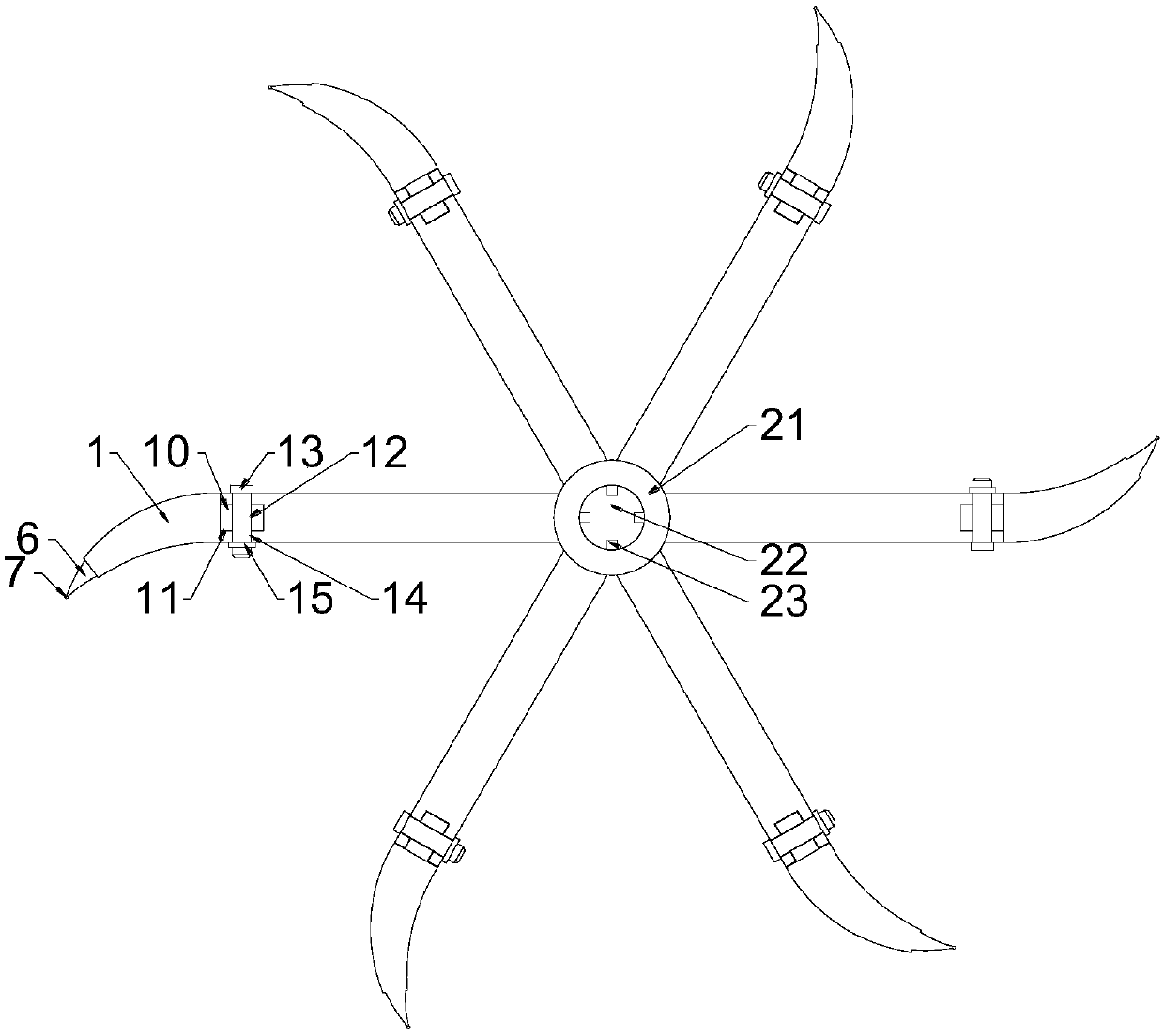

[0029] see Figure 1~4 , an impeller blade for shutting down a fan, comprising an impeller blade 20, a fan block 1 is provided at the front end of the impeller blade 20, a telescopic cavity 2 is provided at the front portion of the fan block 1, a telescopic block 6 is provided at the front end of the telescopic cavity 2, and the telescopic block 6 is near the bottom end The block wall is provided with a first slider 5, the front end of the first slider 5 is provided with a fixed ball 4, the inner wall of the telescopic chamber 2 is provided with a first slideway 3 for locking the fixed ball 4, and the telescopic chamber 2 is provided with a stretching ball. The spring 9, the extension spring 9 is between the telescopic block 6 and the fan block 1.

[0030] In this example, the fan block 1 is fixed on the front end of the impeller blade 20. When the impeller blade 20 rotates inside the blower fan, there is a certain gap between the telescopic block 6 at the front end of the fan...

Embodiment 2

[0032] see Figure 1~4 , an impeller blade for shutting down a fan, comprising an impeller blade 20, a fan block 1 is provided at the front end of the impeller blade 20, a telescopic cavity 2 is provided at the front portion of the fan block 1, a telescopic block 6 is provided at the front end of the telescopic cavity 2, and the telescopic block 6 is near the bottom end The block wall is provided with a first slider 5, the front end of the first slider 5 is provided with a fixed ball 4, the inner wall of the telescopic chamber 2 is provided with a first slideway 3 for locking the fixed ball 4, and the telescopic chamber 2 is provided with a stretching ball. The spring 9, the extension spring 9 is between the telescopic block 6 and the fan block 1.

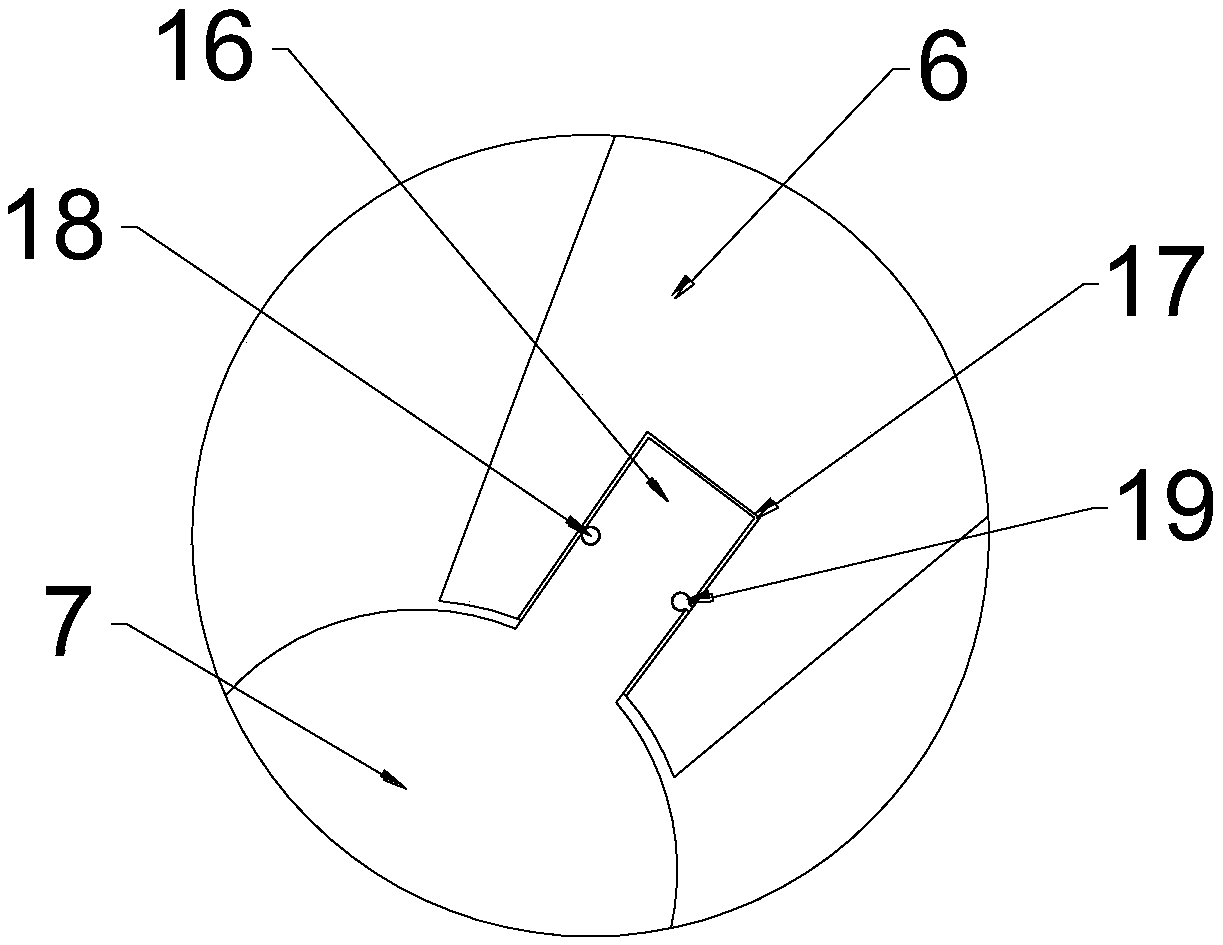

[0033] The front end of the telescopic block 6 is narrow and the rear end is wide, the surface of the telescopic block 6 is arc-shaped, and the narrow front end reduces the contact surface between the telescopic block 6 and the inn...

Embodiment 3

[0036] see Figure 1~4 , an impeller blade for shutting down a fan, comprising an impeller blade 20, a fan block 1 is provided at the front end of the impeller blade 20, a telescopic cavity 2 is provided at the front portion of the fan block 1, a telescopic block 6 is provided at the front end of the telescopic cavity 2, and the telescopic block 6 is near the bottom end The block wall is provided with a first slider 5, the front end of the first slider 5 is provided with a fixed ball 4, the inner wall of the telescopic chamber 2 is provided with a first slideway 3 for locking the fixed ball 4, and the telescopic chamber 2 is provided with a stretching ball. The spring 9, the extension spring 9 is between the telescopic block 6 and the fan block 1.

[0037]The front end of the telescopic block 6 is provided with a soft silica gel ball 7, which can reduce the wear rate between the shut-off fan and the telescopic block 6, thereby effectively discharging materials through the shut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com