Material tray placing and storing device and production line

A technology of retracting and placing device and material tray, which is used in transportation and packaging, stacking of objects, etc., can solve the problem of inconvenience of the material tray, and achieve the effects of neat and rapid retraction, high stability and high speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0042] The tray retracting device provided in this embodiment is a further improvement on the tray retracting device provided in Embodiment 1.

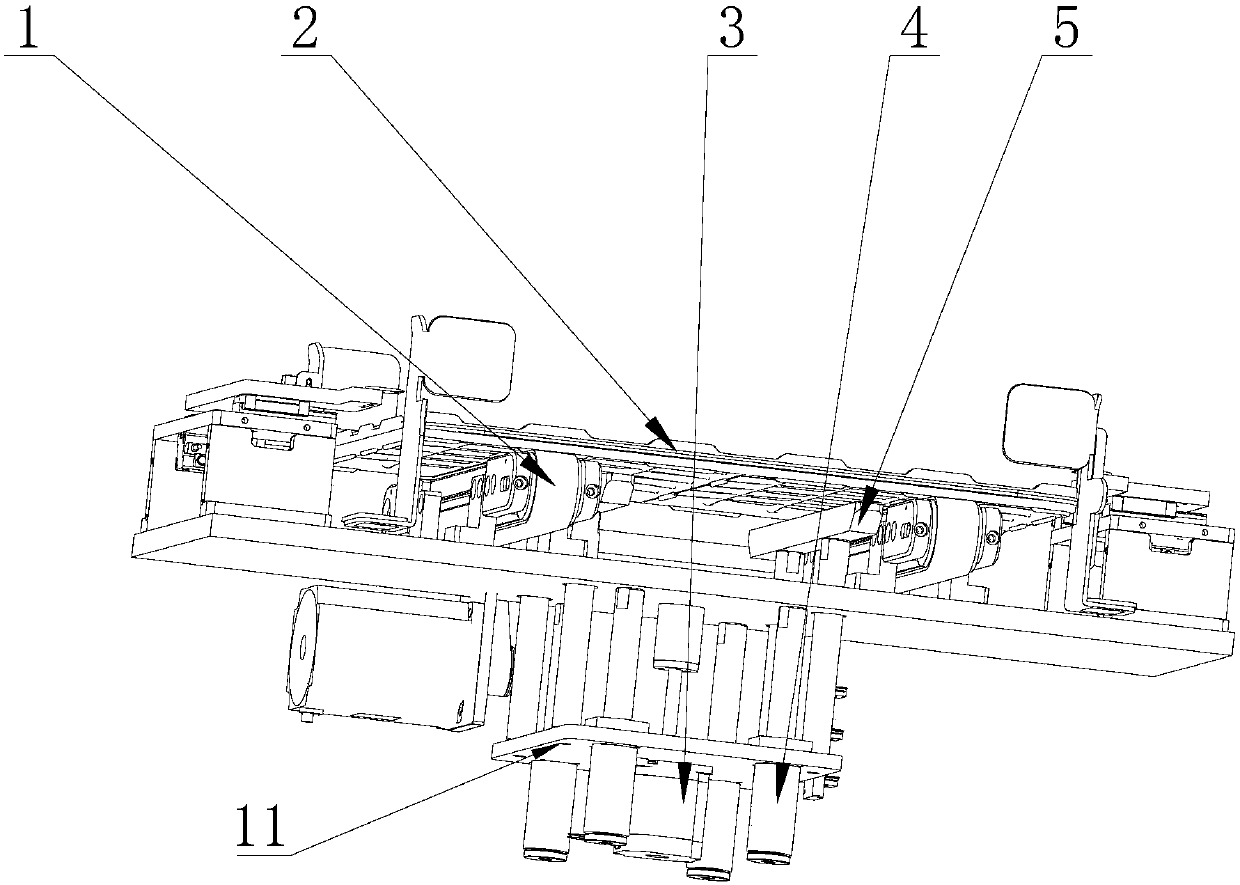

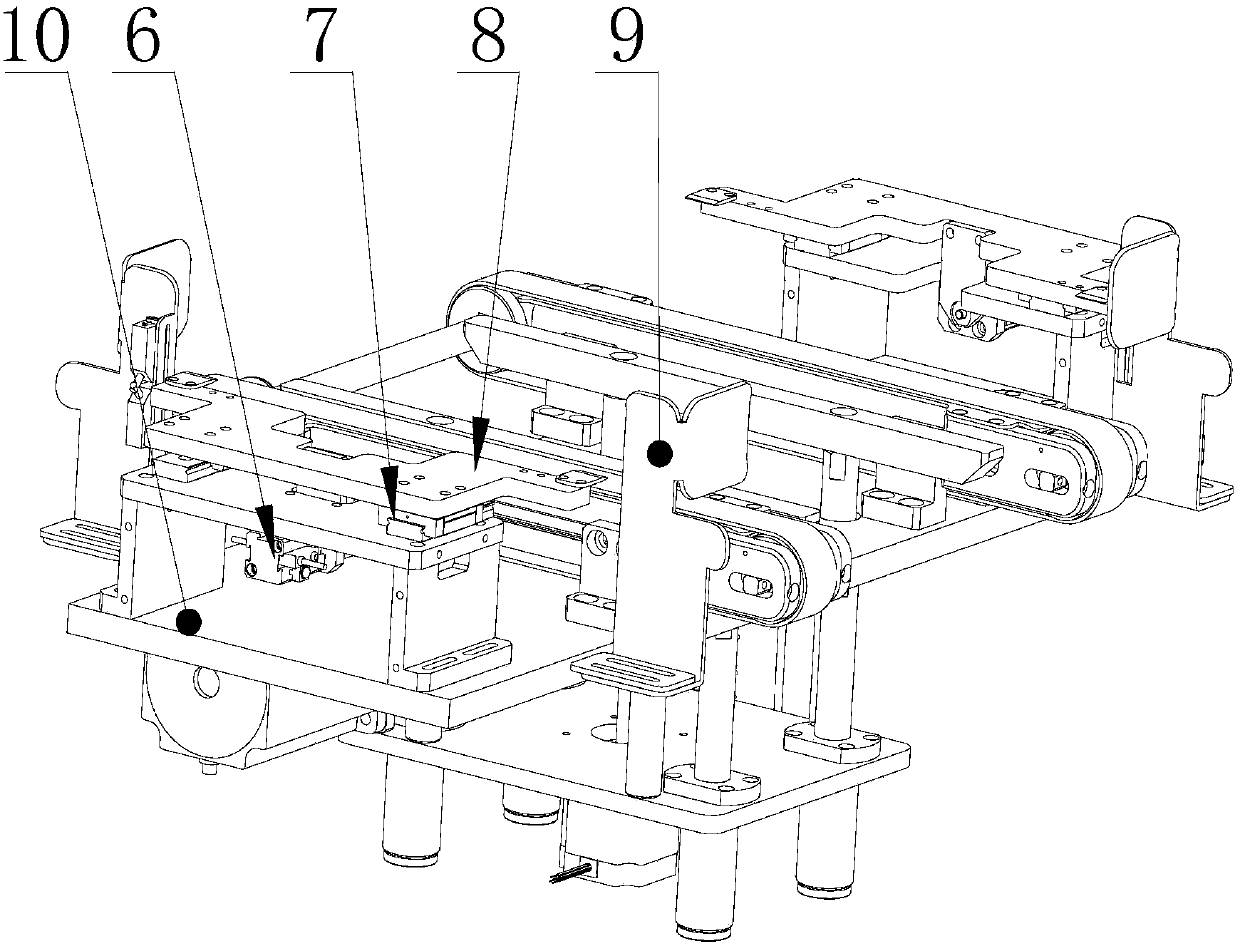

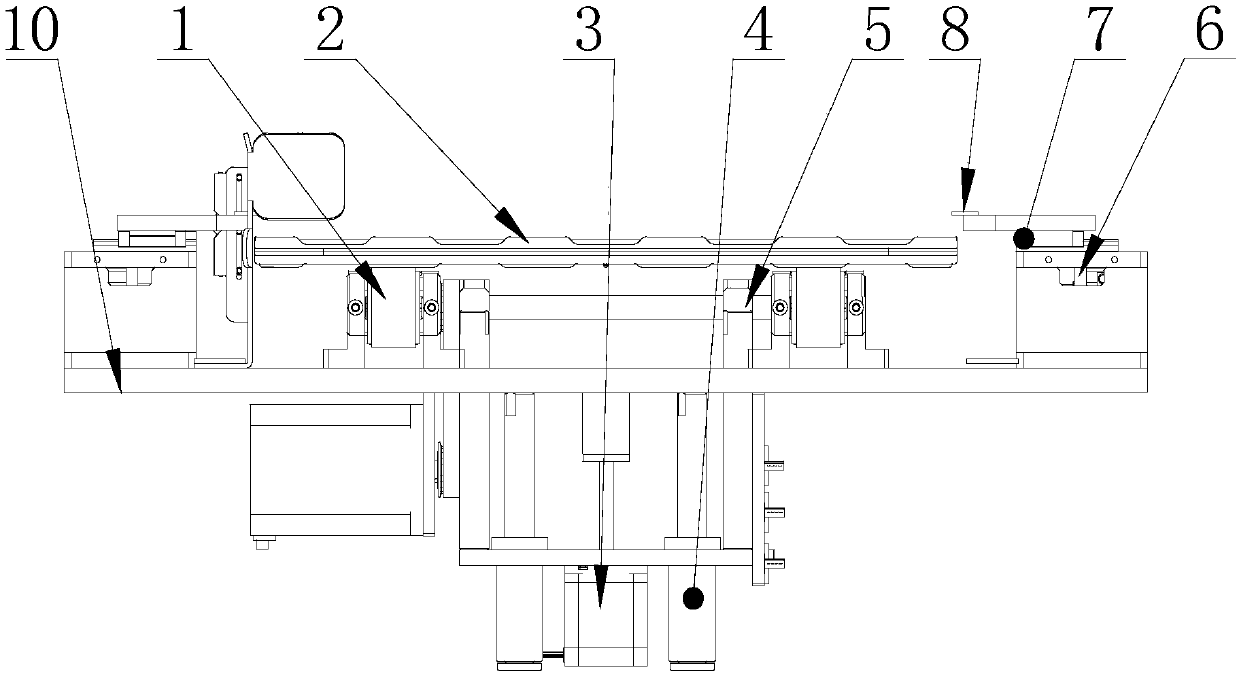

[0043] Specifically, as Figure 1-4As shown, in this embodiment, a tray retracting device is provided, and the tray retracting device includes a mounting panel 10, a sliding support assembly, a lifting support assembly and two conveyor belts 1 parallel to each other;

[0044] The lifting support assembly includes a support mounting plate 11, a driving device and a plurality of supports 5;

[0045] A plurality of the support members 5 are installed on the support mounting plate 11 and located between the two conveyor belts 1;

[0046] The drive device is installed on the installation panel 10 to drive the support installation plate 11 up and down;

[0047] Described driving device adopts stepping screw motor 3, the body of described stepping screw motor 3 and the underside of described installation panel 10; Described supporting inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com