Rolling device for nanometer bainitic steel production

A technology of bainitic steel and coiling device, which is applied in the direction of coiling strips, transportation and packaging, thin material processing, etc., to achieve good coiling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

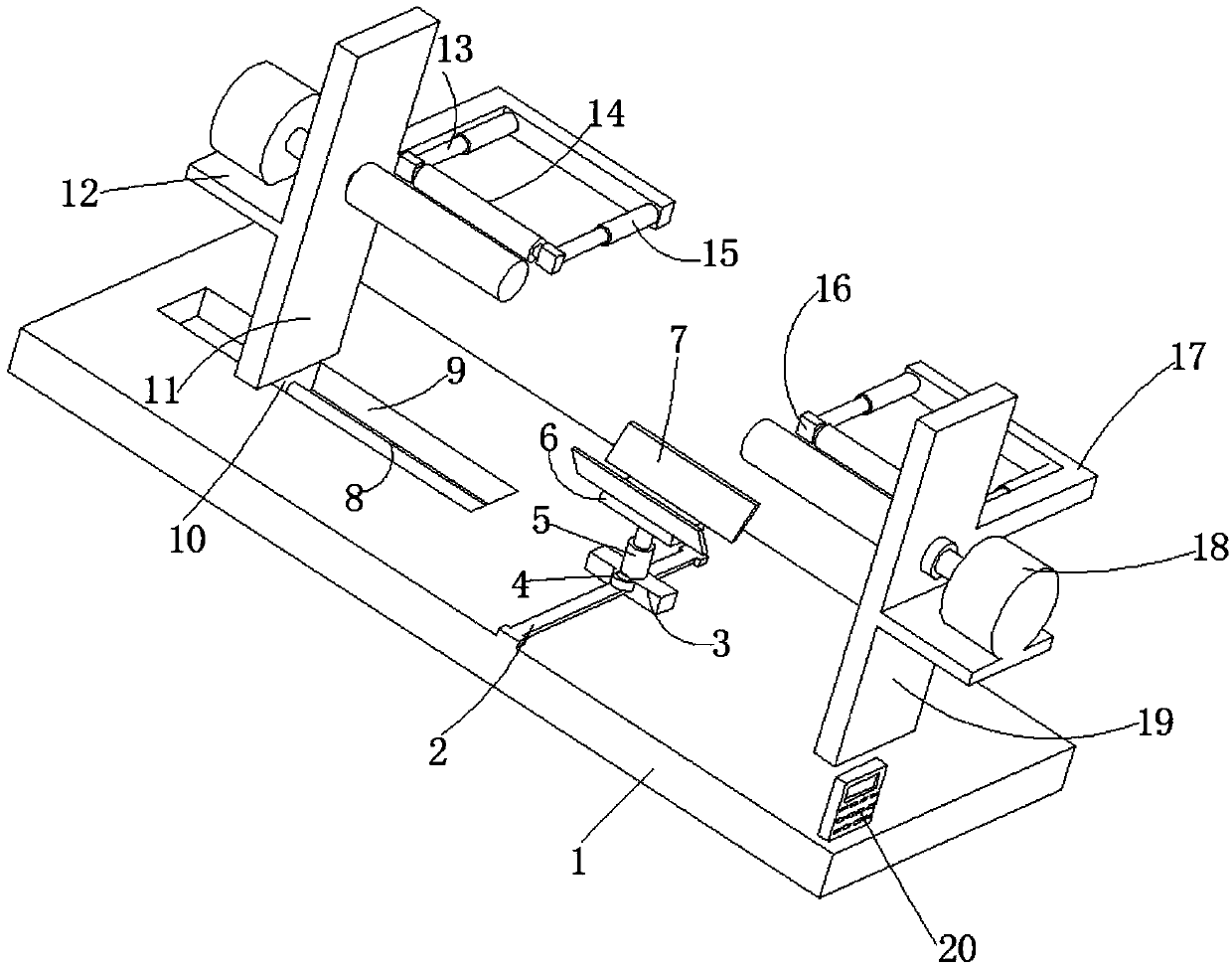

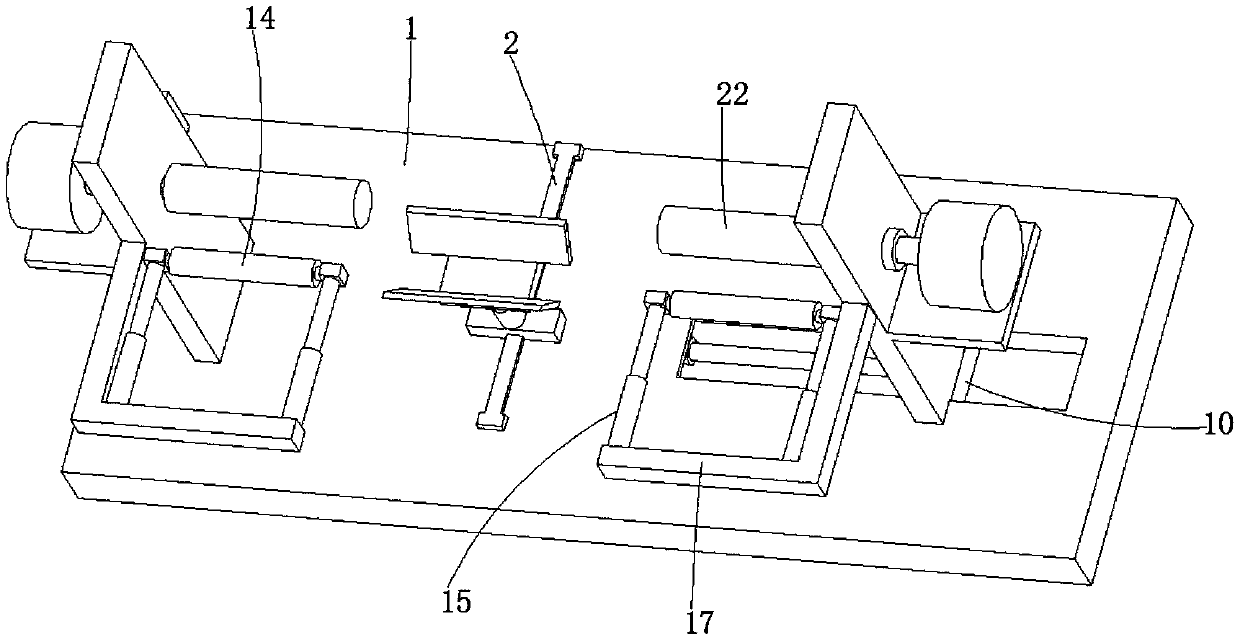

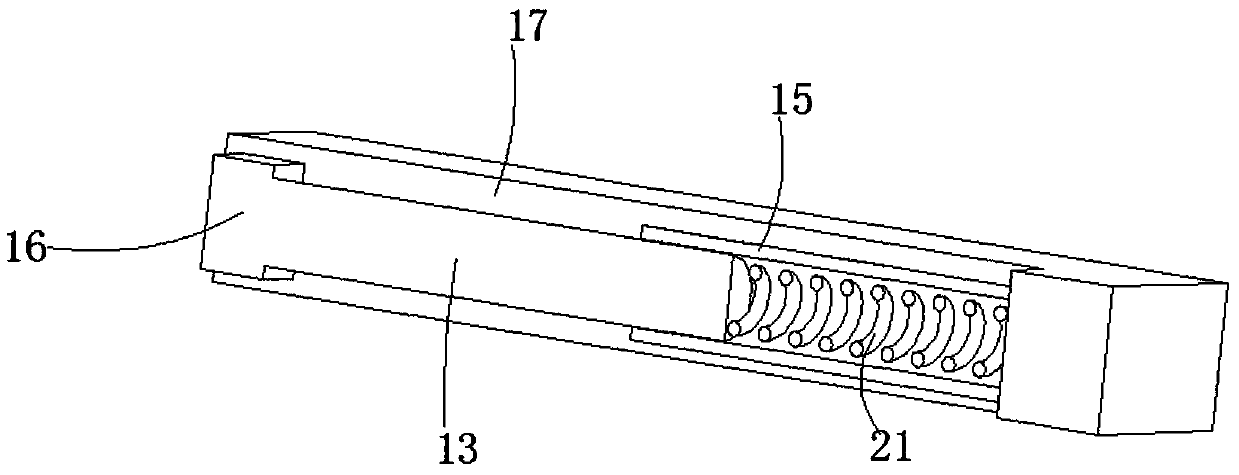

[0031] A coiling device for the production of nano-bainitic steel, comprising a bottom plate 1, a slide rail 2, a slider 3, a first cylinder 5, a horizontal plate 6, an inclined plate 7, a second cylinder 8, a moving block 10, and a movable support plate 11. Mounting plate 12, sliding rod 13, flattening roller 14, casing 15, mounting block 16, L-shaped rod 17, fixed support plate 19, spring 21 and air expansion roller 22, the top right side of the bottom plate 1 is fixedly connected with a fixed support plate 19, the base plate 1 is provided with a transverse groove 9, and the second cylinder 8 is fixedly installed in the transverse groove 9, the output end of the second cylinder 8 is fixedly connected with a moving block 10, and the moving block 10 is fixedly connected with a movable support plate 11, The second cylinder 8 drives the moving block 10 to move, and the moving block 10 drives the movable support plate 11 to move, so that the distance between the movable plate supp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ultimate tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com