Polypropylene for insulation of power cables

A power cable and polypropylene resin technology, applied in the field of polypropylene resin, can solve the problems of increased cost, reduced flexibility, and reduced physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

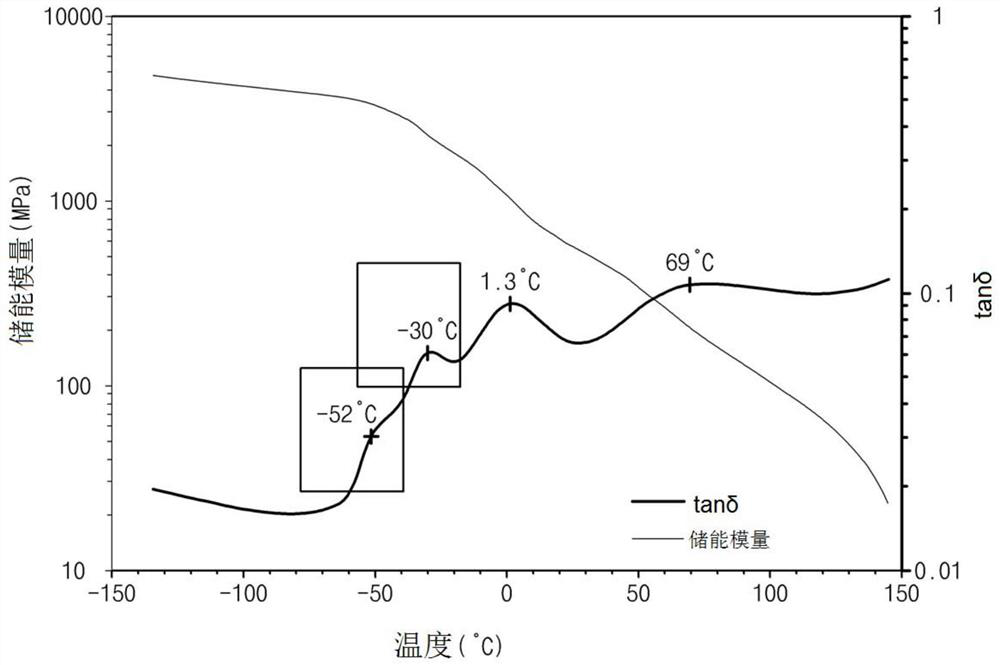

Image

Examples

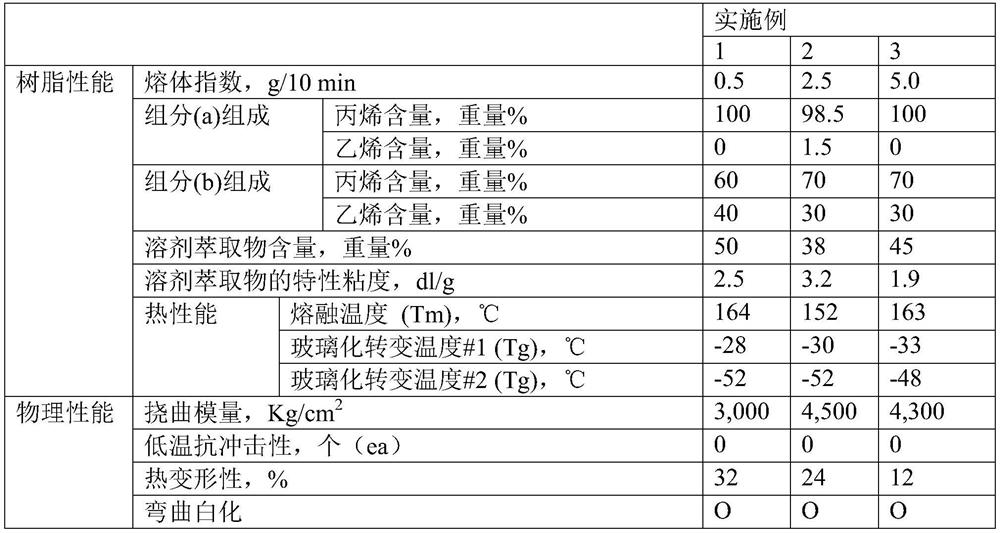

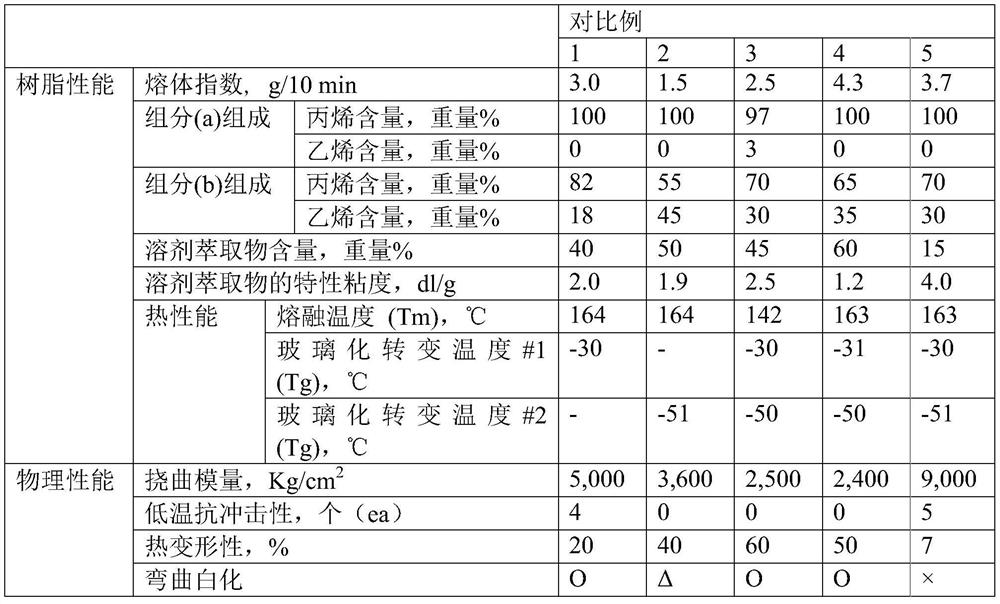

Embodiment 1-3 and comparative example 1-5

[0035]The ethylene-propylene impact copolymers prepared in the inventive examples and comparative examples were prepared using Mitsui's Hypol process for the preparation of polypropylene, where two bulk reactors and two gas phase reactors are connected in series and a continuous polymerization process is possible . Ziegler-Natta catalysts using internal donors with phthalate groups. Triethylaluminum was used as cocatalyst and dicyclopentyldimethoxysilane as donor. The operating temperature and pressure of the first and second stage reactors (which are bulk reactors) are 68 to 75°C and 30 to 40kg / cm 2 and 68 to 75°C and 25 to 35kg / cm 2 . The operating temperature and pressure of the third and fourth stage reactors (which are gas phase reactors) are 75 to 82 ° C and 15 to 20 kg / cm 2 and 68 to 75°C and 10 to 17kg / cm 2 . Propylene is injected separately into the first, second and third stage reactors to produce propylene homopolymer, or ethylene is additionally injected into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com