A strain of Lactobacillus paracasei and its application

A technology for lactobacillus and paracheese, which is applied in the field of microorganisms and microbial fermentation, can solve the problems of low 2,3-butanedione content, etc., and achieve the effects of enhancing milk flavor and improving market competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Embodiment 1: the screening of bacterial strain of the present invention

[0067] (1) Obtain a suitable dilution gradient and culture

[0068] Weigh 0.5mL from the traditional fermented koji sample in Aba Autonomous Prefecture, Sichuan, add it to 4.5mL sterile water, and then take 0.5mL bacterial solution and dilute it in 4.5mL sterile water, so that the concentration of the sample is diluted to 10 -4 50 μL of each of the four bacterial suspensions with a dilution of 10 to 104 were spread on the MRS solid medium, and cultured at 37° C. for 46 to 48 hours.

[0069] (2) Separation and purification

[0070] A typical single colony was selected by the plate streaking method, and strains with excellent traits were obtained after repeating the cultivation and selection operation. This operation obtained three strains in total, namely strain CGMCC No.14023, strain 15M9 and strain 5G2.

[0071] (3) Gram staining and catalase test

[0072] Pick single colonies of the above st...

Embodiment 2

[0073] Embodiment 2: the identification of bacterial strain of the present invention

[0074] (1) PCR amplification of 16S rDNA

[0075] Take out the liquid culture medium after shaking and mixing in a 1mL glycerol tube, centrifuge and discard the supernatant, wash with 1mL sterile water for 2 times, centrifuge and discard the supernatant, and use it as a template for colony PCR.

[0076] a) 50 μL of PCR system, including 25 μL of Mix, 1 μL of 27F, 1 μL of 1492R, and 23 μL of ddH2O.

[0077] The primers used were 27F as shown in SEQ ID NO.2: AGAGTTTGATCCTGGCCTCA and 1492R as shown in SEQ ID NO.3: GGTTACCTTGTTACGACTT, and the length of the amplified fragment was 1500 bp.

[0078] b) PCR conditions:

[0079] Lid: 105°C mBY-16s V: 20 μL

[0080] DNA double strands were denatured at 94°C for 10min, cooled at 50°C for 30s at 94°C for 30s, rapidly raised to 72°C for 80s, and cycled 29 times, and finally kept at 72°C for 7min.

[0081] (2) Agar gel electrophoresis (80mL)

[0082...

Embodiment 3

[0086] Embodiment 3: the application of bacterial strain of the present invention

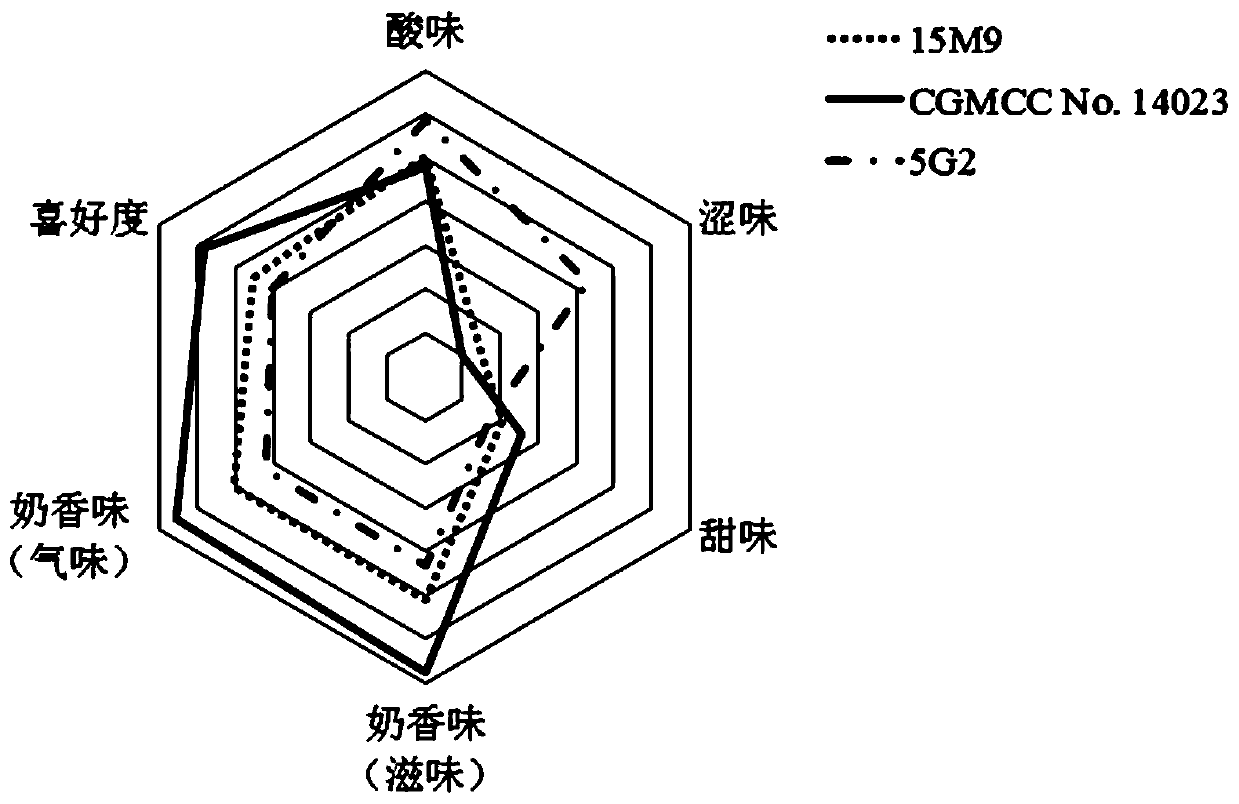

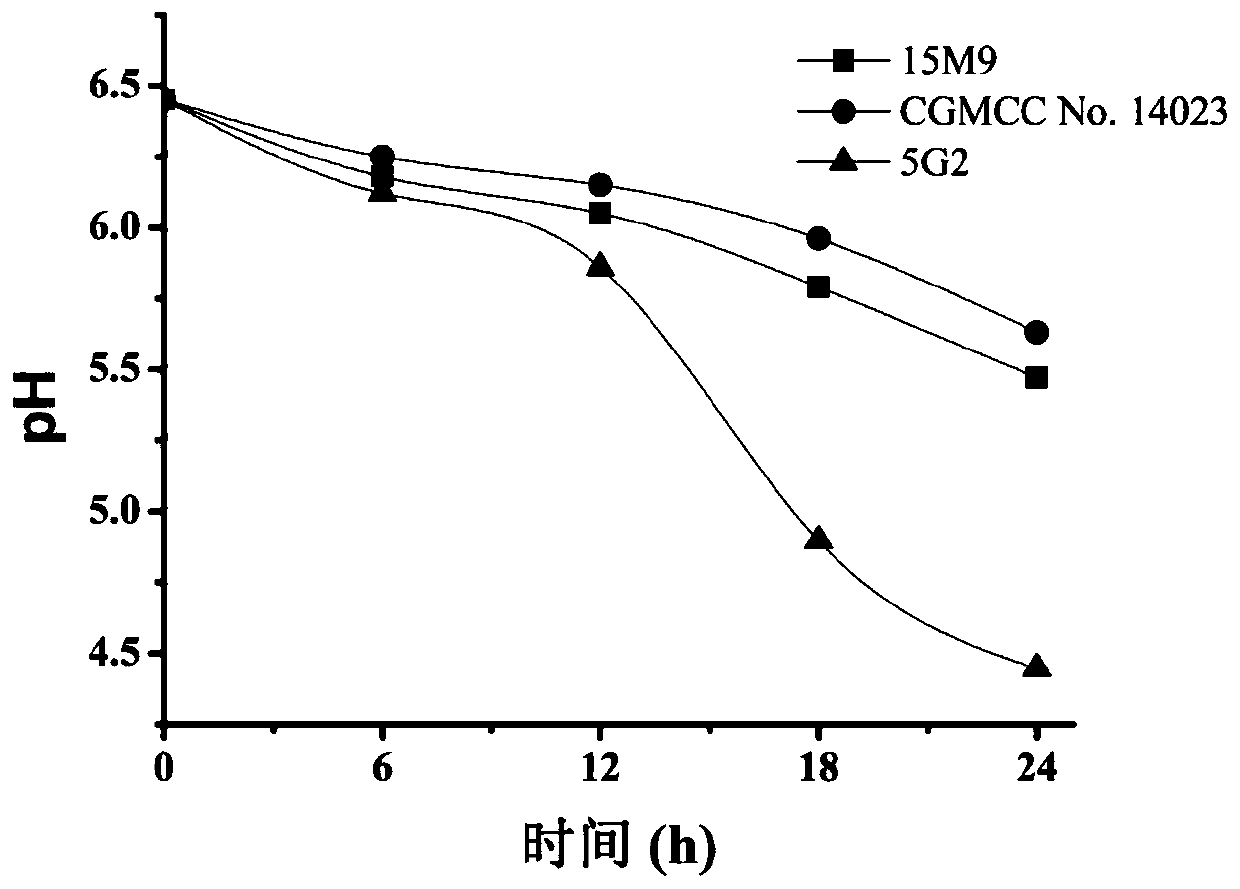

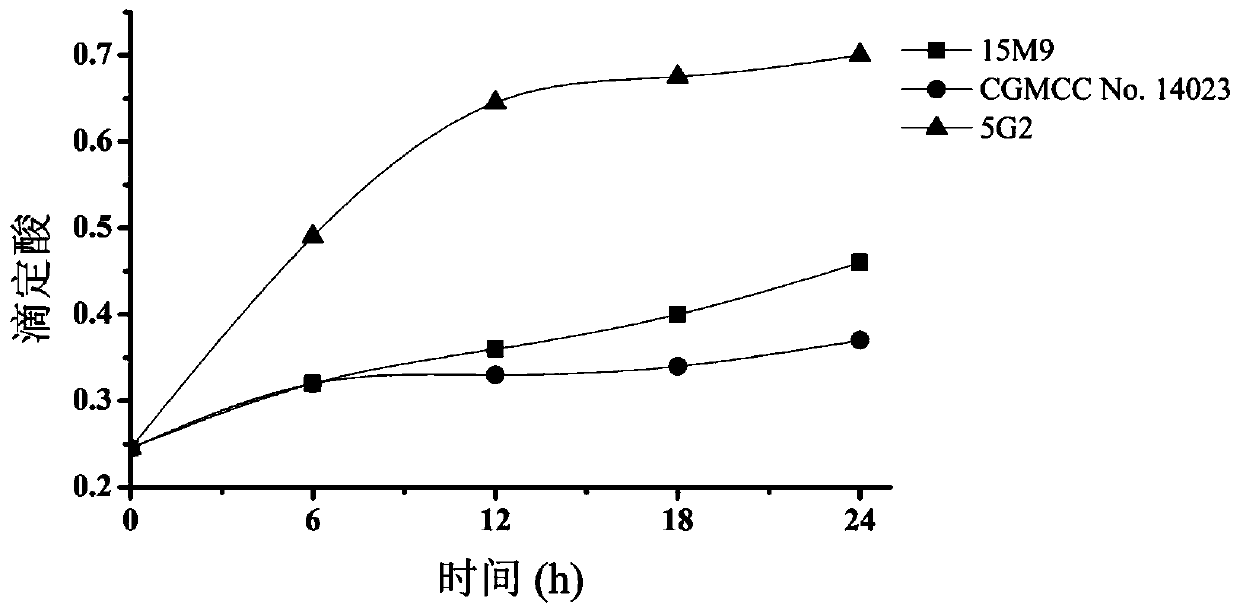

[0087] Inoculate Lactobacillus paracasei 15M9, Lactobacillus paracasei 5G2 and Lactobacillus paracasei CGMCCNo.14023 stored at -80°C in MRS liquid medium respectively, culture them at 37°C for 24 hours, subculture 2 to 3 times, and take bacteria 80 μL of the solution was inoculated in a headspace phase bottle (containing 2 mL of 20% fat cream), and placed at 20°C for 24 hours for fermentation. During this period, samples were taken every 6 hours, and the fermentation samples were tested for 2,3-butanedione. Content, sensory evaluation, pH and titratable acidity detection (the content detection results of 2,3-butanedione are shown in Table 1, and the pH detection results are shown in Table 2, figure 1 , titratable acidity detection results are shown in Table 3, figure 2 , see sensory evaluation results image 3 ).

[0088] As can be seen from Table 1, the 2,3-butanedione output produced by L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com