Experimental device and method for evaluating drilling fluid anti-collapse performance

An experimental device, drilling fluid technology, used in earth-moving drilling, wellbore/well components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

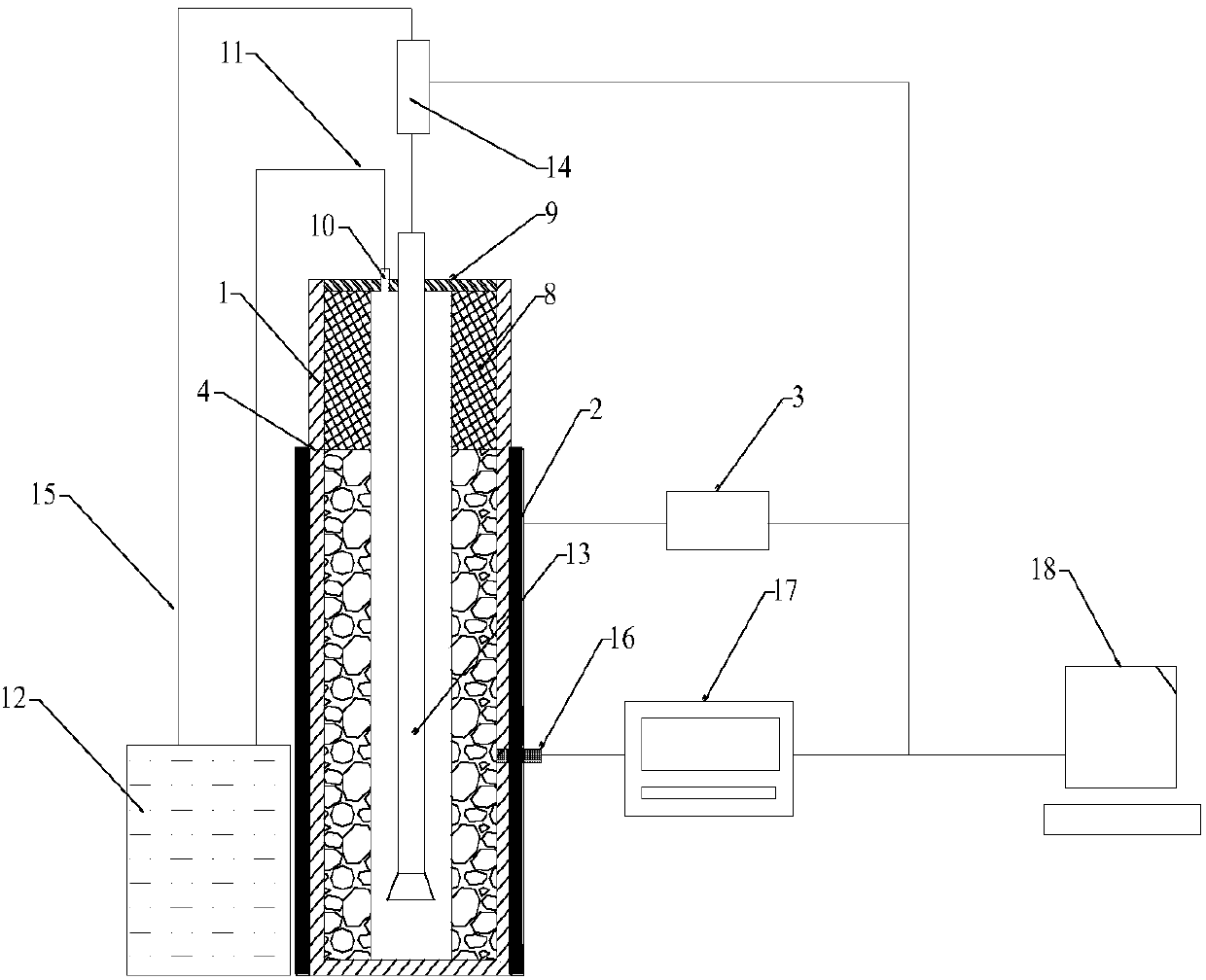

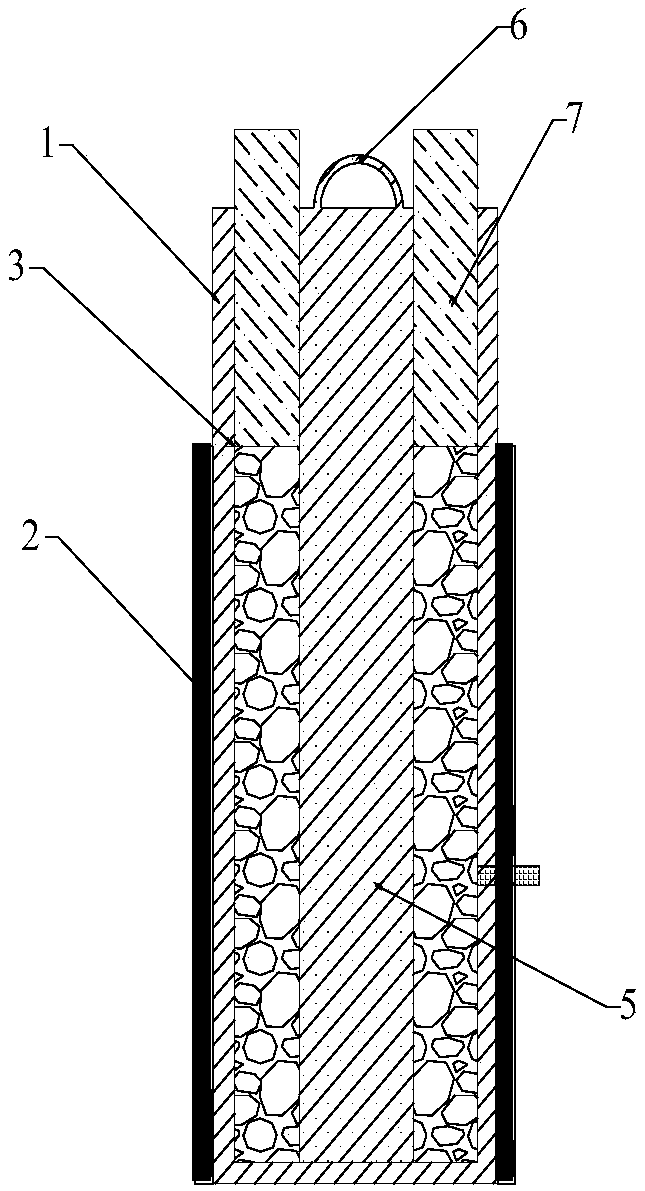

[0042] During the test, put the solid column 5 in the middle of the cylinder body 1; weigh 5.0kg of bentonite and 25.0kg of natural hard and brittle mudstone (from the brown hard and brittle mudstone at 3150-3200m in the North 8 well of Sinopec Northeast Oil and Gas Company, structural Location: the southern end of the Dahan fault outburst in the fault depression, geographical location: 2.42km southeast of Longfeng Village, Changling Town, Changling County, Songyuan City, Jilin Province) Joining the annular space between the cylinder body 1 and the solid column 5, in the ring Overburden block 7 is placed on the ground, the mixture of easily hydratable clay and rock samples is compacted to the position of scale line 4, and the overburden block 7 is taken out, thereby simulating the well wall of easily hydratable clay mineral cemented rock in the well.

[0043] The solid column 5 is lifted out by the handle 6, and the filling block 8 is placed on the upper part of the simulated wel...

Embodiment 2

[0047] Using the operation steps and test conditions of Example 1, only the experimental slurry 1 was replaced with the experimental slurry 2, and the washed and dried rock sample in the cylinder 1 was weighed, which was recorded as D1.

Embodiment 4

[0049] Using the operating steps and test conditions of Example 1, only the experimental slurry 1 was replaced with the experimental slurry 3, and the washed and dried rock sample in the cylinder 1 was weighed, which was recorded as D2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com