Brake device of hollow rotary joint in pile hole

A technology of rotary joint and braking device, which is applied to the drilling driving device, braking actuator, mechanical equipment and other directions in the wellbore, can solve the problems of stop of hollow rotary joint, impossible salvage, and inability to increase the probability of hole collapse. , to increase the service life, the structure is convenient, and the quality of the drilling is guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

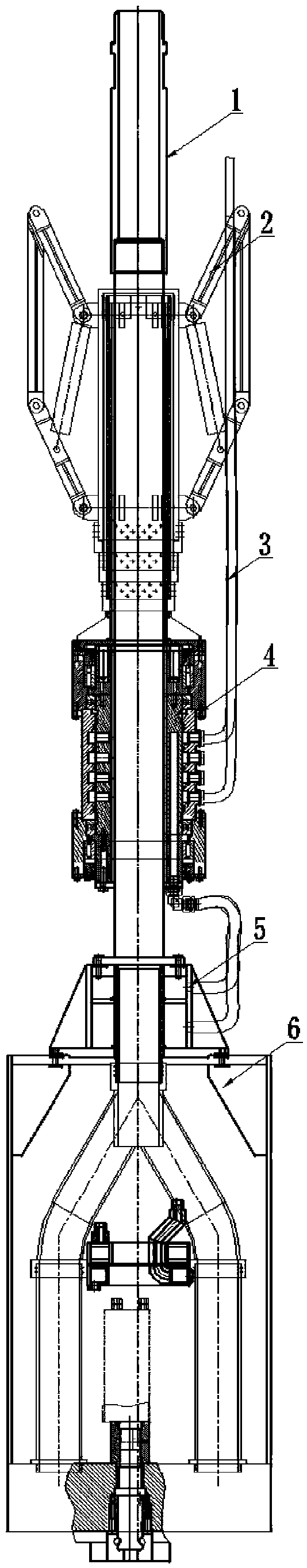

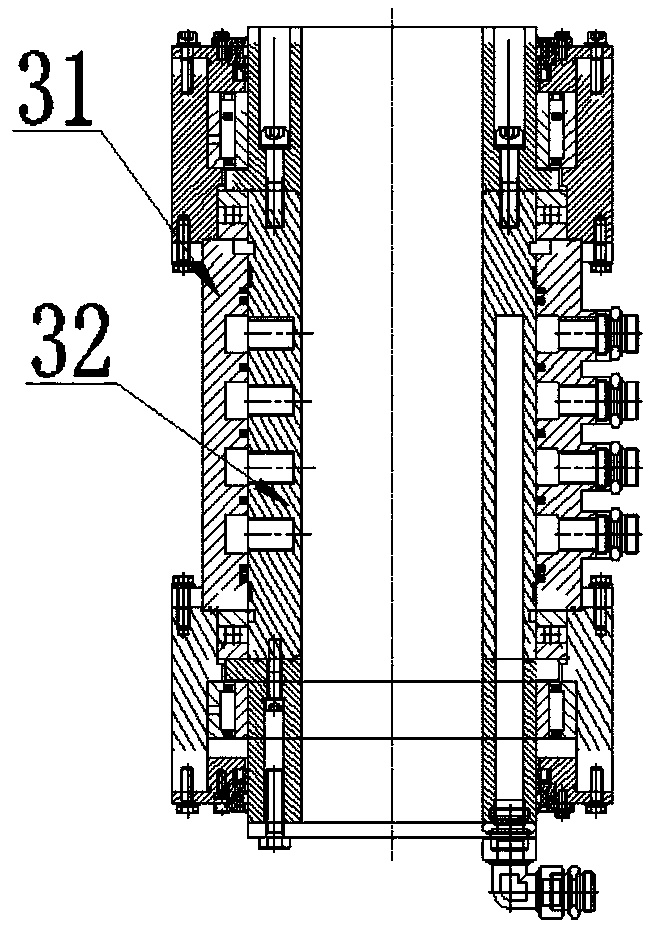

[0038] A brake device for preventing rotation of a hydraulic oil pipe installed on a hollow swivel joint in a pile hole. The brake device includes a brake, a transmission shaft and a hollow swivel joint; The drill pipe is connected to the power head of the ground drilling rig; the lower part is connected to the oil collector, and the oil collector is fixed on the hydraulic down-the-hole hammer or pneumatic down-the-hole hammer to transmit the torque to the hydraulic down-the-hole hammer or pneumatic down-the-hole hammer;

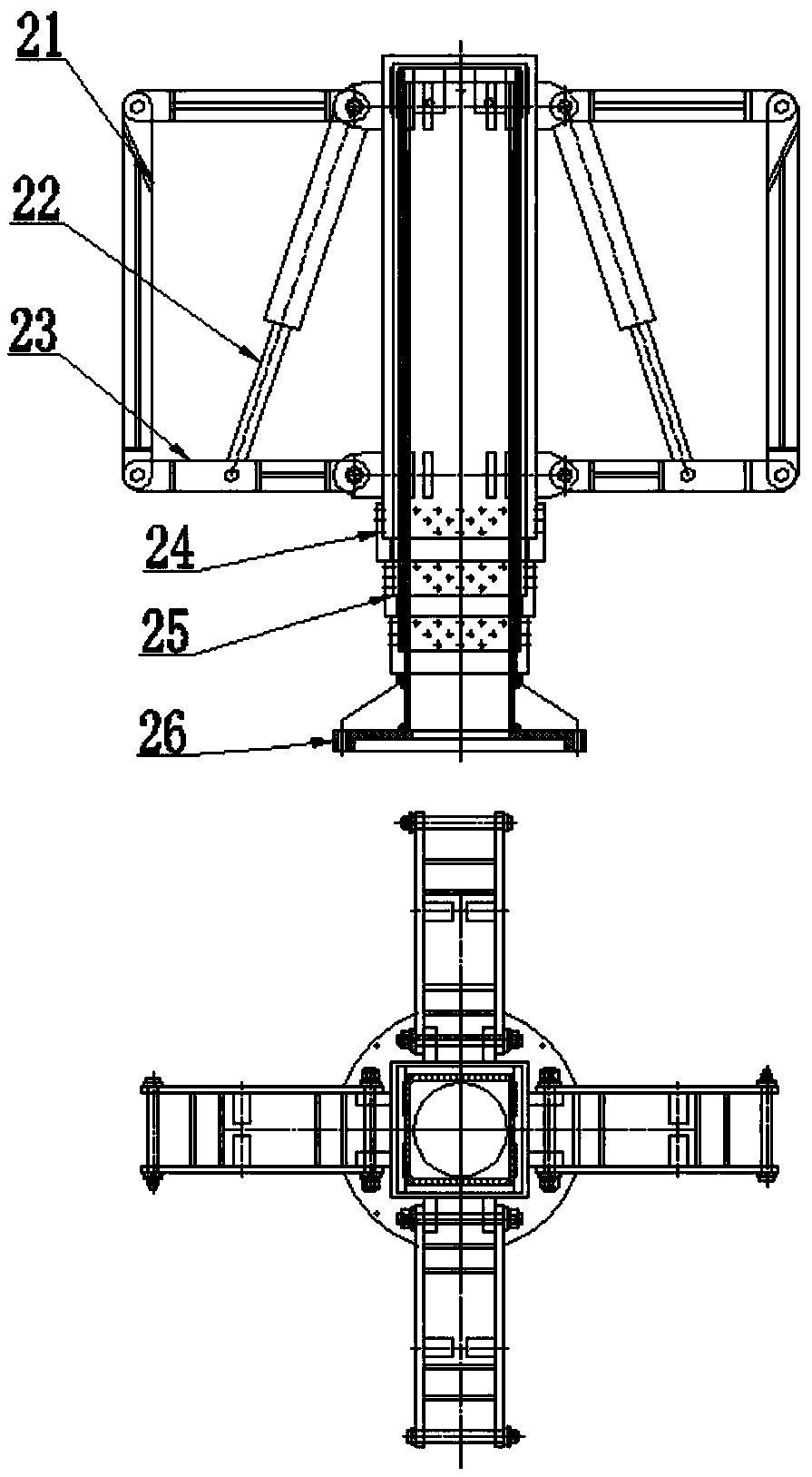

[0039] The brake is composed of a wall support, a tension cylinder, a beam, a bracket fixing seat, two telescopic arms and one telescopic arm; the wall support is connected with the upper and lower pins of the cross beam to form a parallelogram structure, which is driven by the tension cylinder. The crossbeam and the pin shaft of the tension cylinder are fixed on the bracket fixing seat. The bracket fixing seat, telescopic 2 arms and telescopic 1 arm are plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com