Eye fundus image inspection device

An inspection device and imaging technology, used in fundus mirrors, eye testing equipment, medical science, etc., can solve the problems that the stability cannot reach the perfect level, the accuracy cannot be controlled to be very precise, and the structural assembly complexity is high. Uniform and clear illumination, clear and accurate fundus imaging, and the effect of solving precision and clarity deficiencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

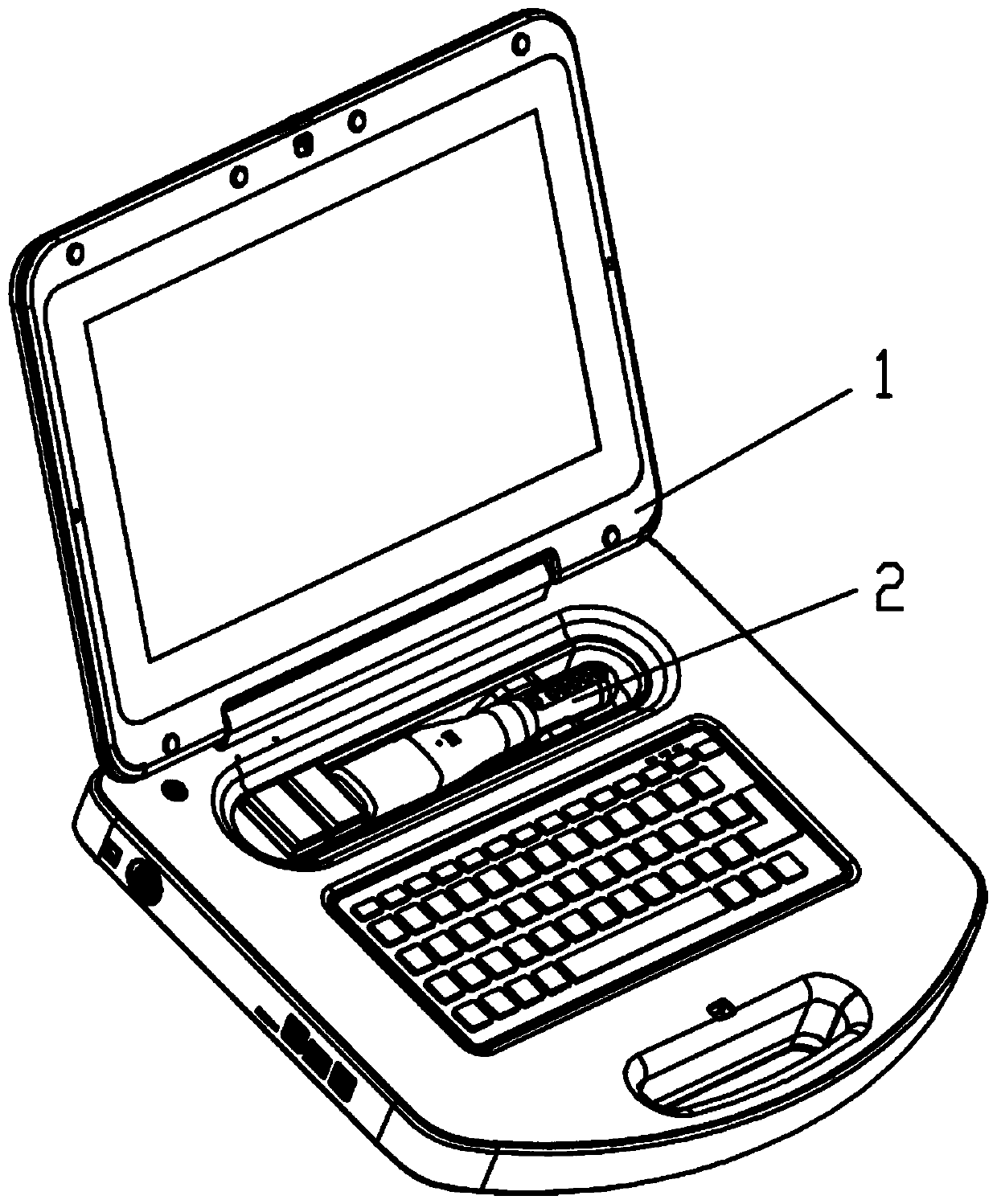

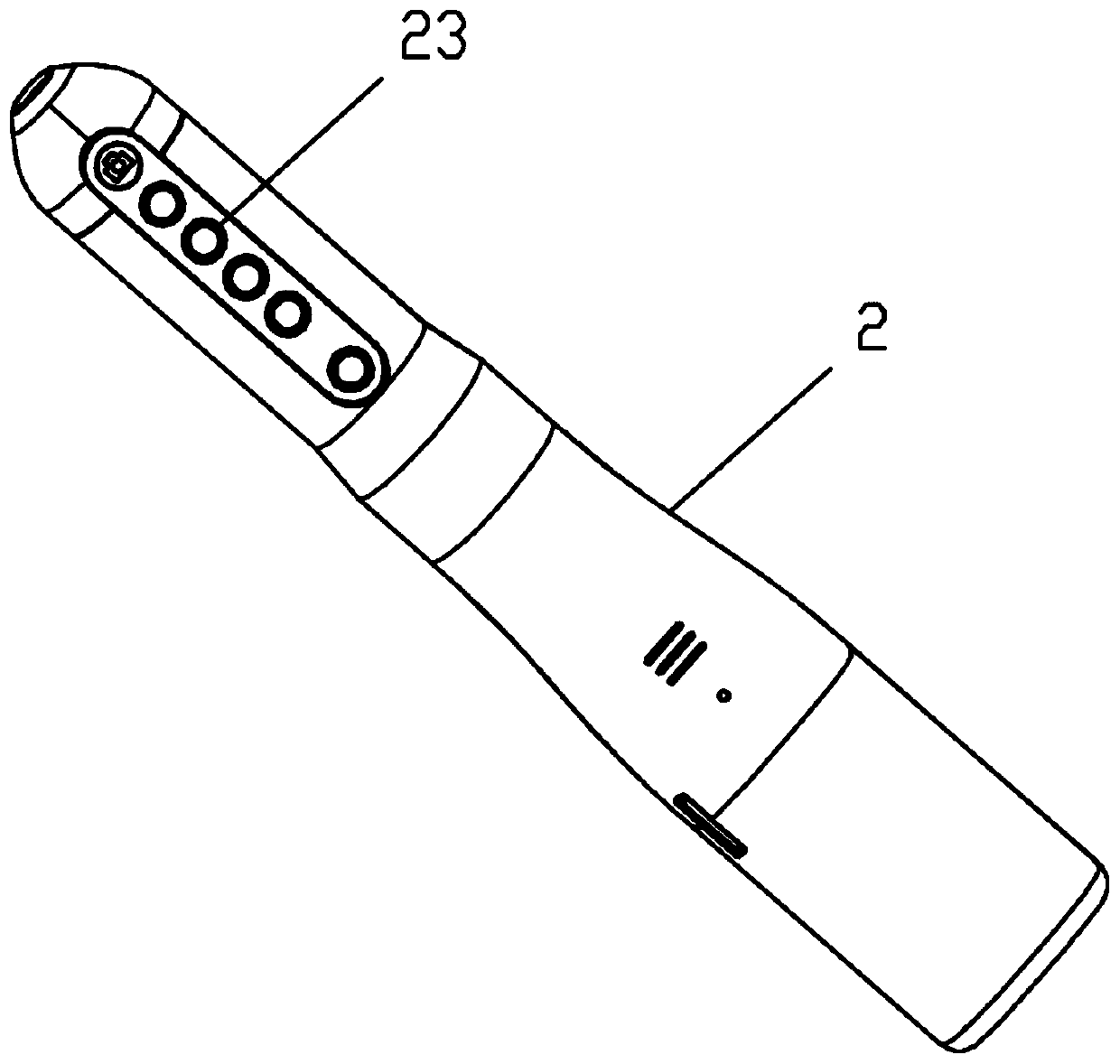

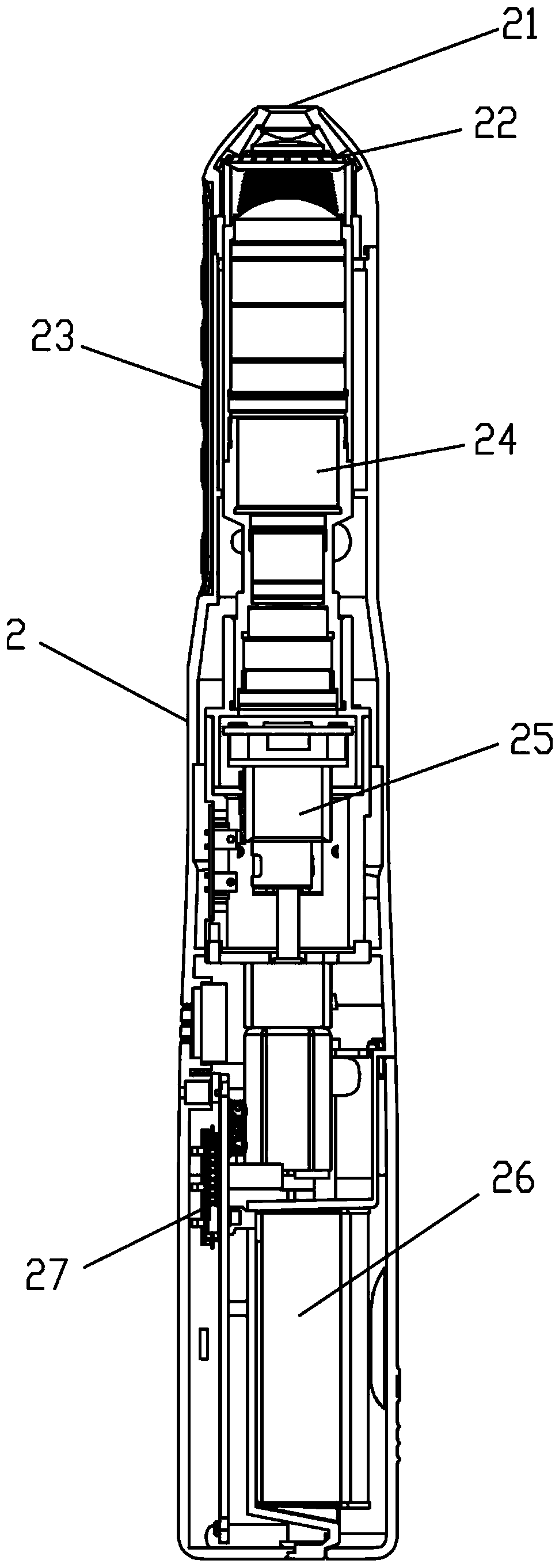

[0040] A fundus image inspection device of the present invention, in its preferred embodiment, please refer to Figures 1 to 3 As shown, the fundus image inspection device includes a fundus camera and an inspection terminal 1. The inspection terminal 1 is a notebook-style smart terminal, which includes a display screen that is partially connected to the host and can be folded onto the host. There is a keyboard, a fundus camera placement slot, a power interface and a variety of data connection ports; the host is equipped with a motherboard, a processor, a memory and a network communication module; the fundus camera placement slot is used to accommodate the fundus camera; the The fundus camera is a straight rod-type fundus camera, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com