durable pile foundation

A technology of durability and pile foundation, applied in sheet pile wall, foundation structure engineering, construction and other directions, it can solve the problems of time-consuming, affecting the physical properties of piles such as tensile and compressive strength, and easy loosening of mechanical connection structure. Reduced damage, increased tensile and compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

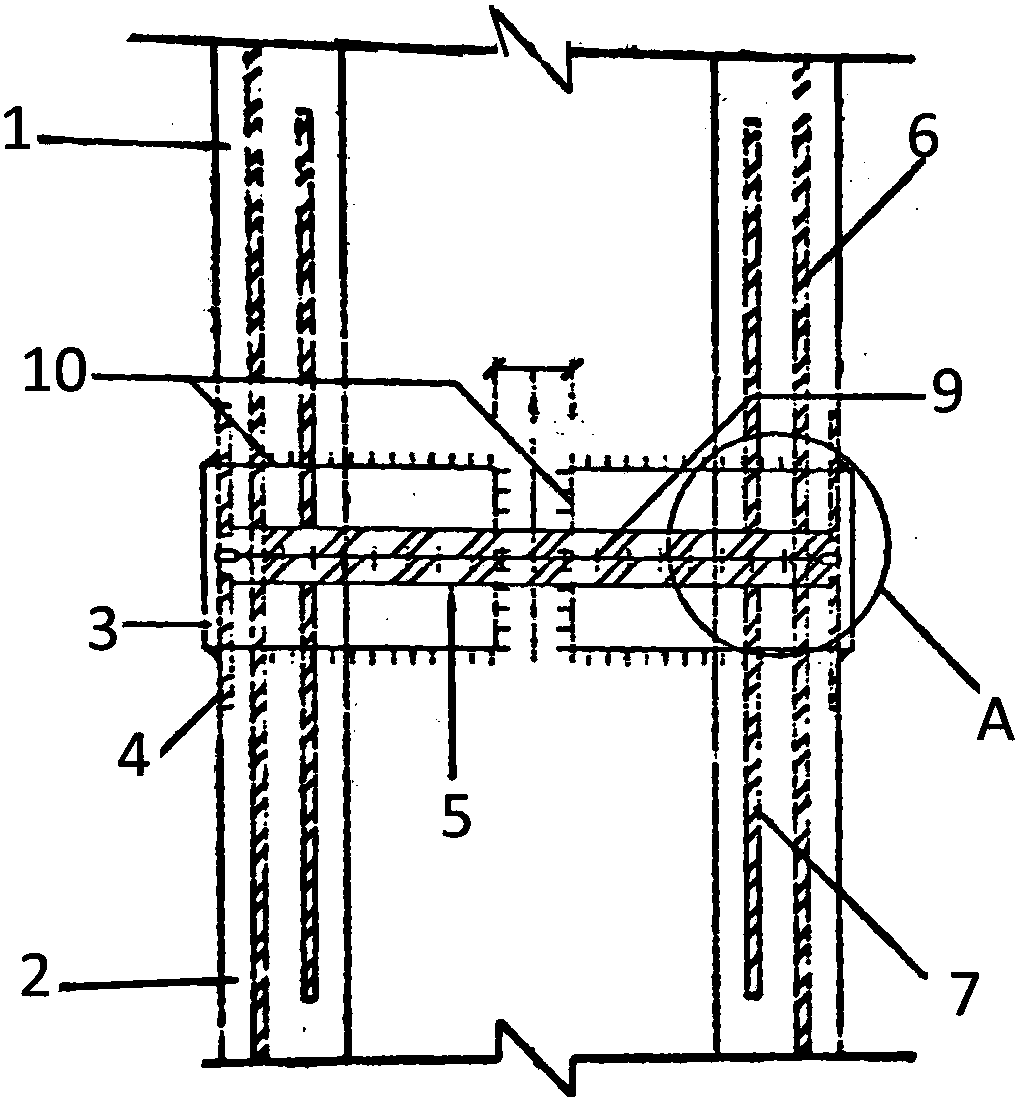

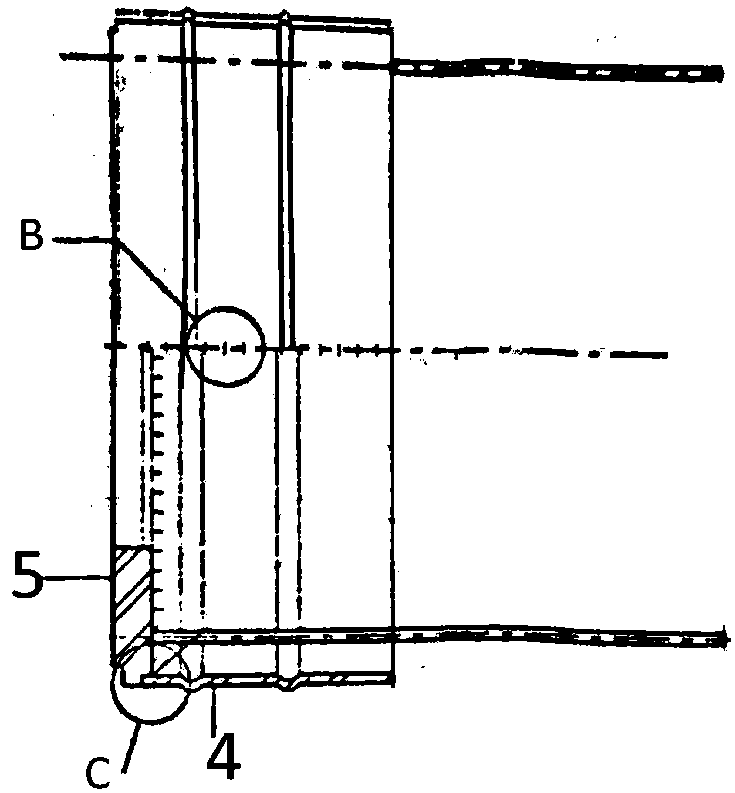

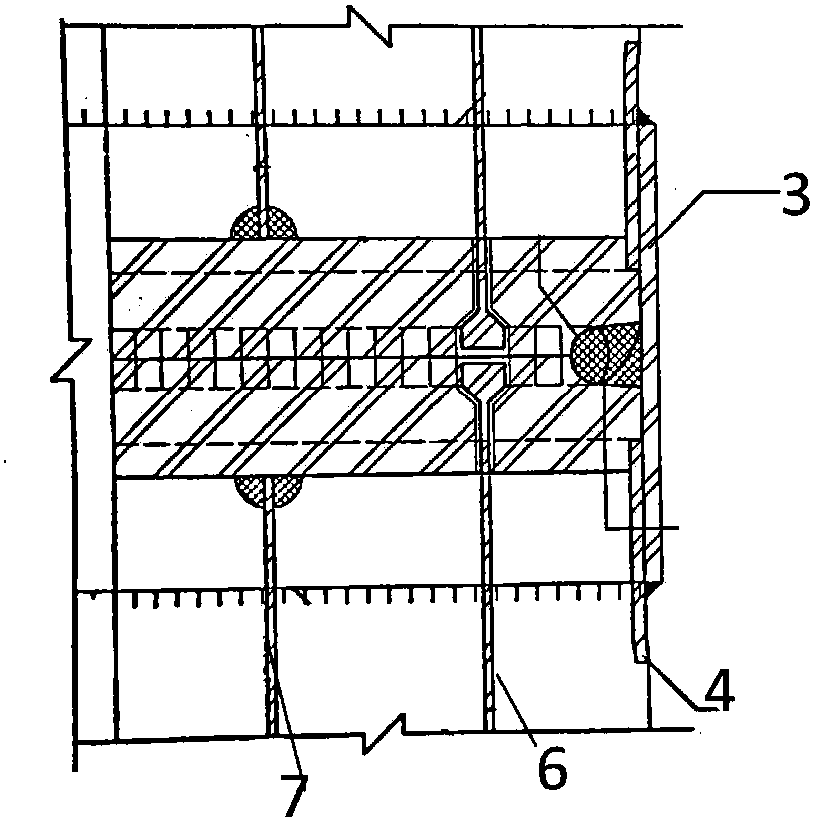

[0026] combined with figure 1 to attach Figure 8 Describe the structure and principle of the present invention.

[0027] Such as figure 1 As shown, when the structure is used to connect prefabricated piles, a reinforced connection structure is provided between the upper section 1 of the prefabricated piles and the lower section 2 of the prefabricated piles to improve the physical properties of the prefabricated piles, especially the tensile, compressive and shear properties. Reduce breakage and damage during construction due to silt layers, isolated stones or foundation excavations. It can be seen from this figure that the ends of adjacent prefabricated piles are provided with pile end plates 5 and pile collars 4 . The pile collar and the pile end plate are welded and fixed, specifically as figure 2 As shown, the pile collar and the pile end plate are welded by submerged arc welding. The connecting plate 3 for reinforcement is welded on the pile hoop 4 along the circumf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com