An energy-saving water collector

A water collector and energy-saving technology, applied in the direction of branch pipelines, mechanical equipment, pipes, etc., can solve the problems of increasing pump power waste, consuming water flow energy, increasing operating costs, etc., to reduce turbulent impact and reduce noise , smooth water effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

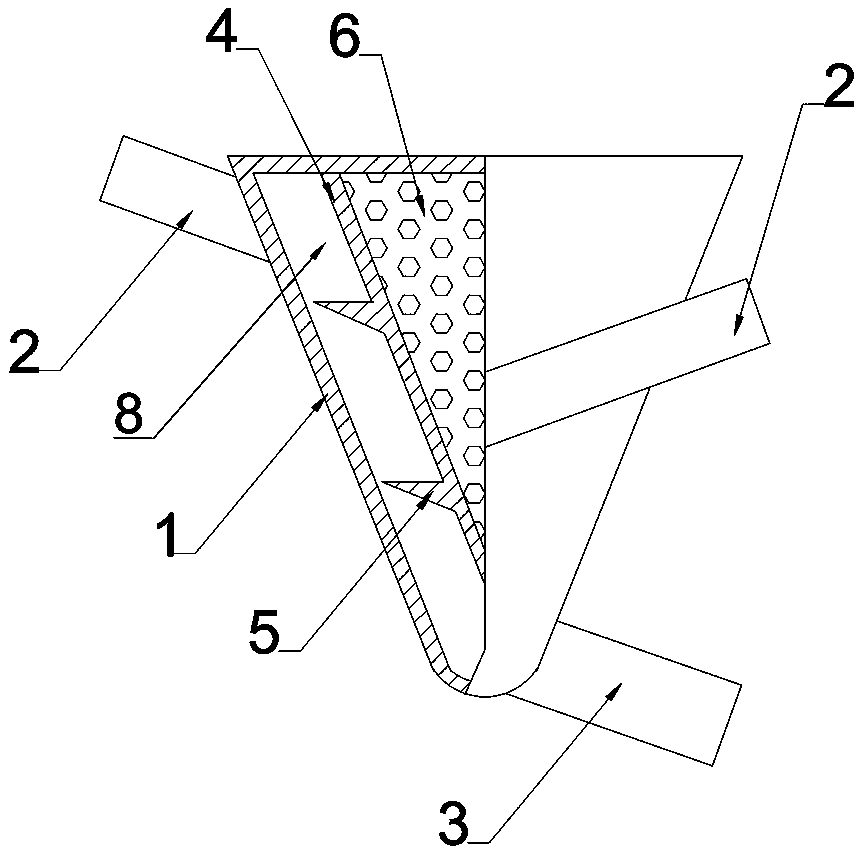

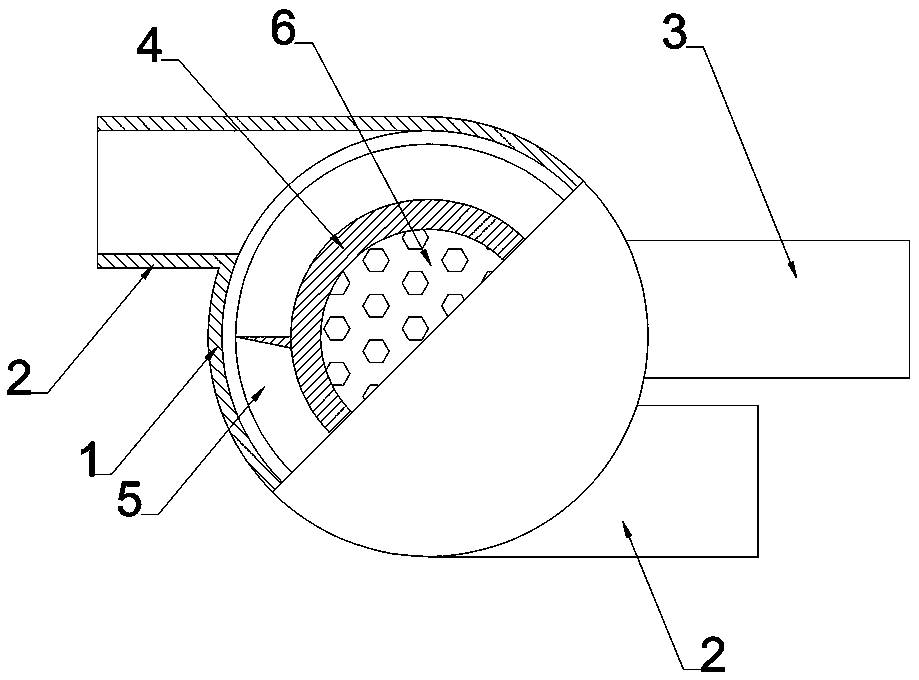

[0028] Such as Figure 1 to Figure 4 As shown, this embodiment is an energy-saving water collector, which includes a housing 1, a water outlet pipe 3 and at least one water inlet pipe 2.

[0029] The casing is conical, and a conical guide core 4 is sleeved in the casing 1; the surface of the casing 1 and the guide core 4 are parallel with a gap 8 therebetween; the guide core 4 ends are connected to the housing 1 by welding or bolts.

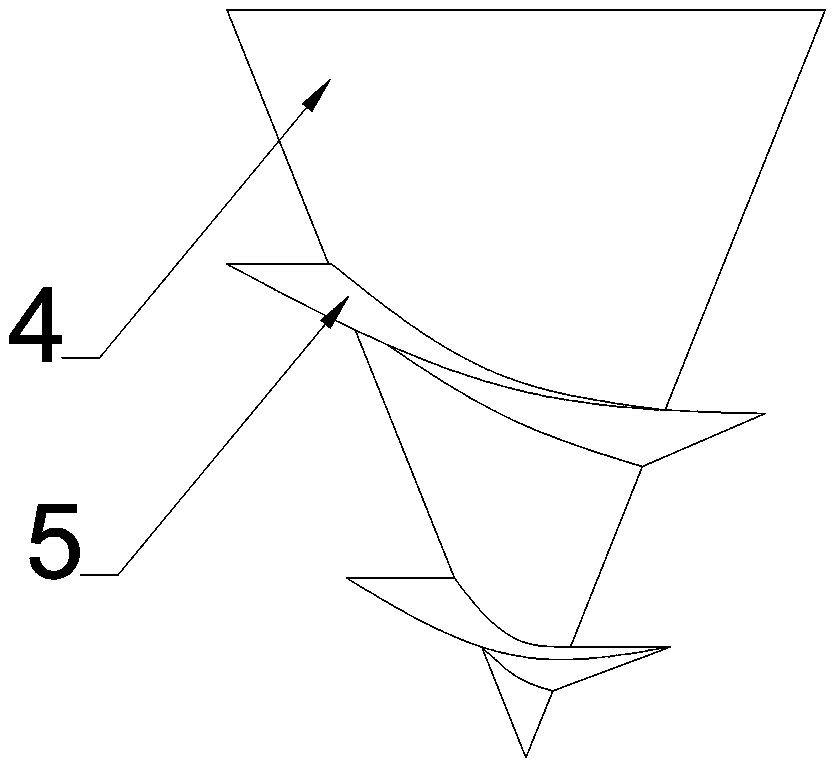

[0030] The outer surface of the guide core 4 is provided with a guide device 5; the guide device 5 is a continuous spiral protrusion. The cross section of the spiral protrusion is a right-angled triangle or an obtuse-angled triangle, and one side of the right-angled side or the obtuse-angled side faces the water inlet direction. This setting method restricts the lateral direction of the water flow (also in the axial direction of the water trap), so that the influent water flow is kept as independent as possible, and it does not interfere with the wa...

Embodiment 2

[0043] This embodiment is also an energy-saving water collector. Compared with embodiment 1, the basic structure is similar, the difference is mainly: the number of water inlet pipes 2 is 3, and the height of the deflector 5 is equal to 1 / 2 of the height of the gap 8. , The distance between the two adjacent spirals of the guide device 5 is the same as the gap; the angle between the water inlet pipe and the water collector axis is 90°; the diameter of the water inlet pipe is 1 / 2 of the height of the gap 8; The diameter of the water pipe is equal to the height of the gap 8; the cone apex angle of the casing and the guide core 4 is 60°.

[0044] During the verification process, it was found that if the height of the spiral protrusion of the diversion device 5 is lower than 1 / 2 of the height of the gap 8, it is difficult to ensure the lateral restriction of the water flow direction. Therefore, it is better to be no less than 1 / 2. This implementation In the example, the height of the ...

Embodiment 3

[0050] This embodiment is also an energy-saving water collector. Compared with embodiment 1, the basic structure is similar, and the main difference is: the number of water inlet pipes 2 is 4; the height of the deflector 5 is the height of the gap 8 3 / 5; the distance between the two adjacent spirals of the guide device 5 is 1.5 times the height of the gap 8; the angle between the water inlet pipe and the axial direction of the water flow in the water collector is 110°; the housing The cone apex angle of the guide core (4) is 90°.

[0051] The diameter of the inlet pipe is 7 / 12 of the height of the gap (8); the diameter of the outlet pipe is 1.5 times the height of the gap (8). According to the circle area formula πr 2 , We can calculate that, in this embodiment, the diameter of the outlet pipe 3 is greater than or equal to the diameter of the inlet pipe 2, that is, 7 / 12 of the height of the gap 8. The arrangement of this embodiment will not cause insufficient drainage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com