Humidity sensor based on a friction nano-generator and a method thereof

A technology of humidity sensor and nanogenerator, applied in triboelectric generators, instruments, scientific instruments, etc., can solve the problem of difficulty in providing continuous operation of power sensor networks, and achieve the effects of good humidity response, stable electrical performance, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The invention will be further described below in conjunction with the accompanying drawings and embodiments.

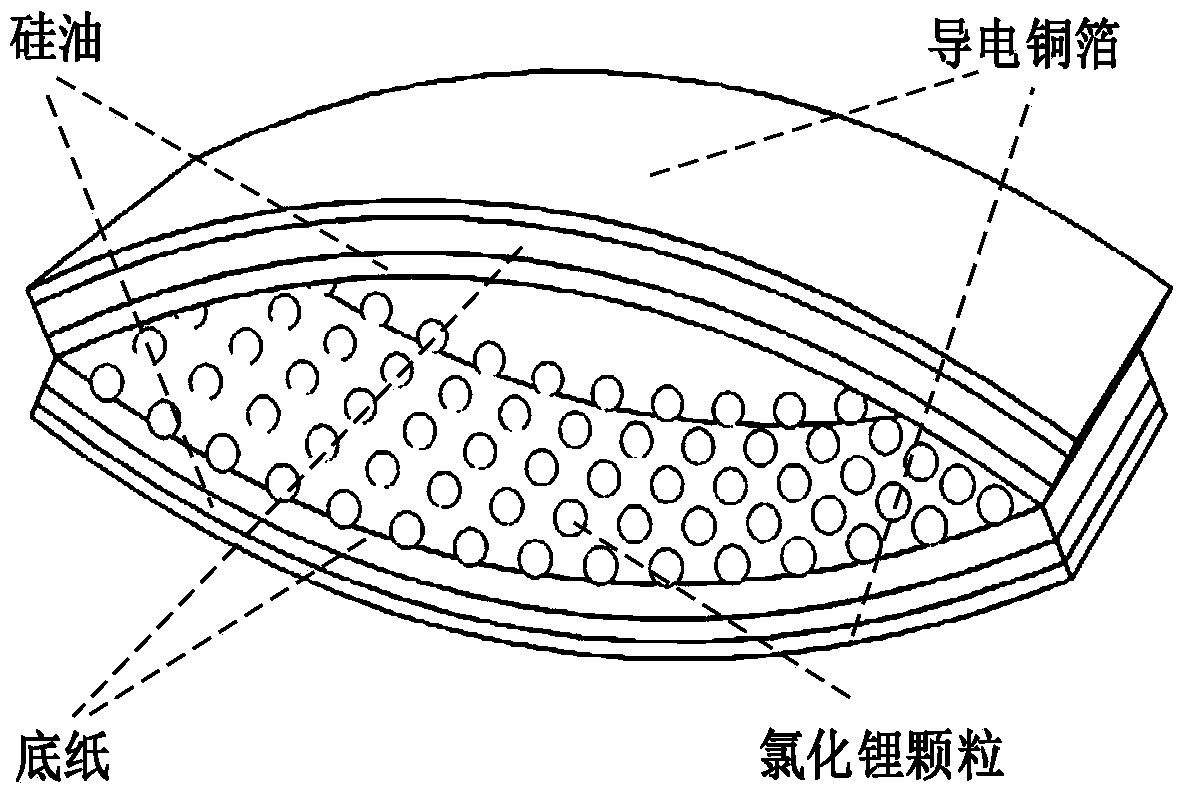

[0034] As we all know, conductive copper foil tape is a common commercial material, which consists of three parts, including copper foil, backing paper and silicone oil. The backing paper and silicone oil form a triboelectric pair, and the copper foil serves as a conductive electrode. At the same time, due to its good sustainability and flexibility, the backing paper plays a supporting role.

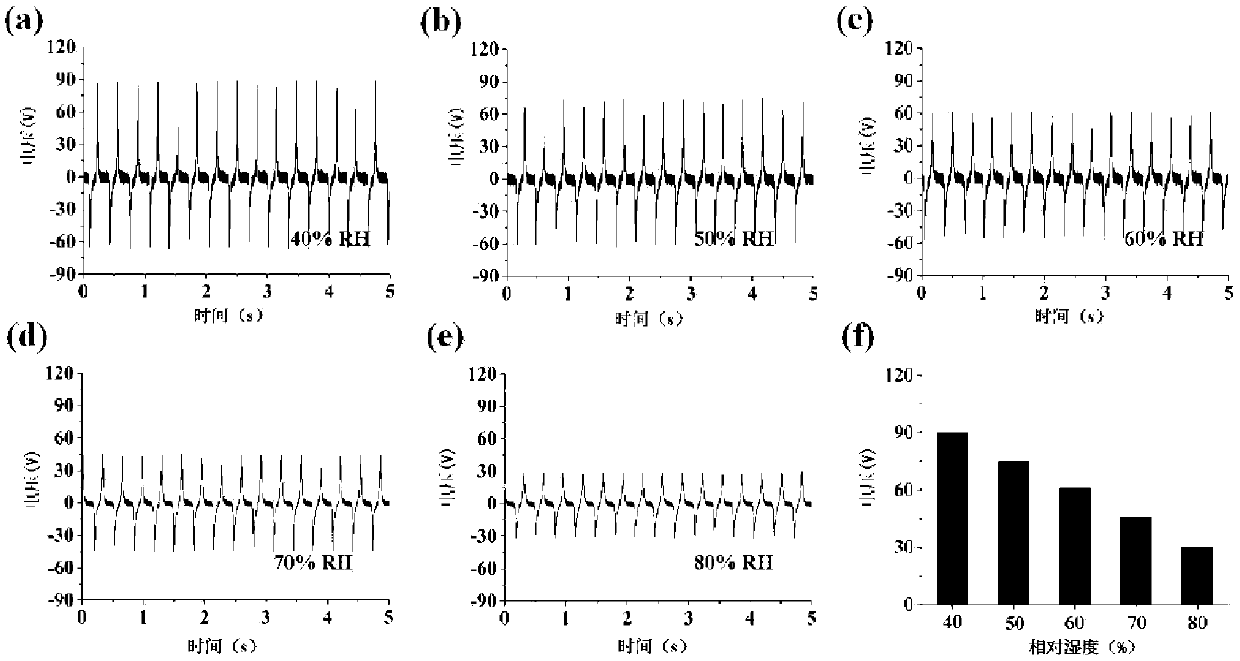

[0035] refer to figure 1 , is the humidity sensor based on the triboelectric nanogenerator described in the present invention, comprises two arched structures up and down; The concave surfaces of the two arched structures are arranged oppositely, and the two ends are bonded to each other; The upper arched structure includes Arranged conductive copper foil, backing paper and silicone oil layer, the lower arched structure includes conductive copper foil, silicone oil laye...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap