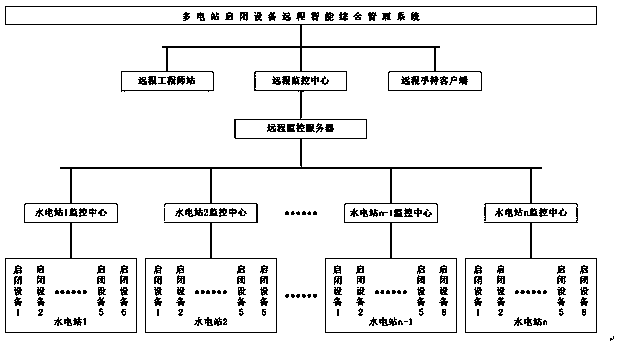

Multi-power-station remote intelligent integrated management system and method for switch-on and switch-off equipment

A technology of comprehensive management and remote monitoring system, applied in the field of remote intelligent comprehensive management system of multi-power station opening and closing equipment, can solve problems such as centralized management and monitoring of disadvantageous equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

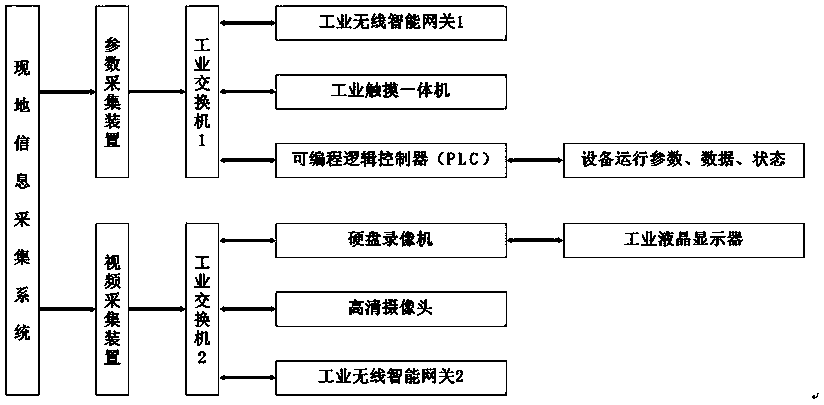

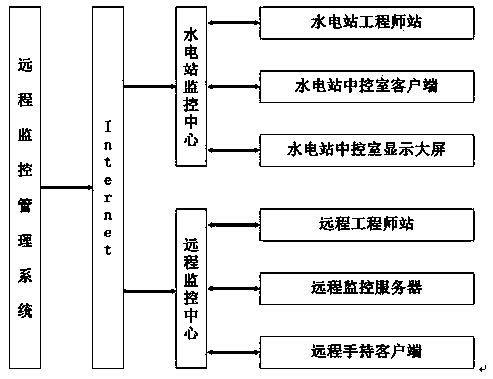

[0028] The remote intelligent comprehensive management system for multi-power station hoisting equipment provided by the present invention includes an on-site information acquisition system and a remote monitoring system; the on-site information acquisition system is connected to the remote monitoring system through a wireless or wired network.

[0029] Such as figure 2 As shown, the on-site information acquisition system includes on-site equipment parameter acquisition systems and on-site equipment video acquisition systems installed in each hydropower station. The on-site equipment parameter acquisition system includes industrial switch I, industrial switch I as the connecting device, connected to PLC, Industrial wireless intelligent gateway I, industrial touch all-in-one machine; PLC is a programmable logic controller, which is set at each hydropower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com