Design method of a high-toughness ultra-thin asphalt wear layer mixture

A technology of asphalt mixture and design method, which is applied in design optimization/simulation, computer-aided design, calculation, etc., and can solve problems such as inability to match the design concept of high-toughness and ultra-thin asphalt wearing layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

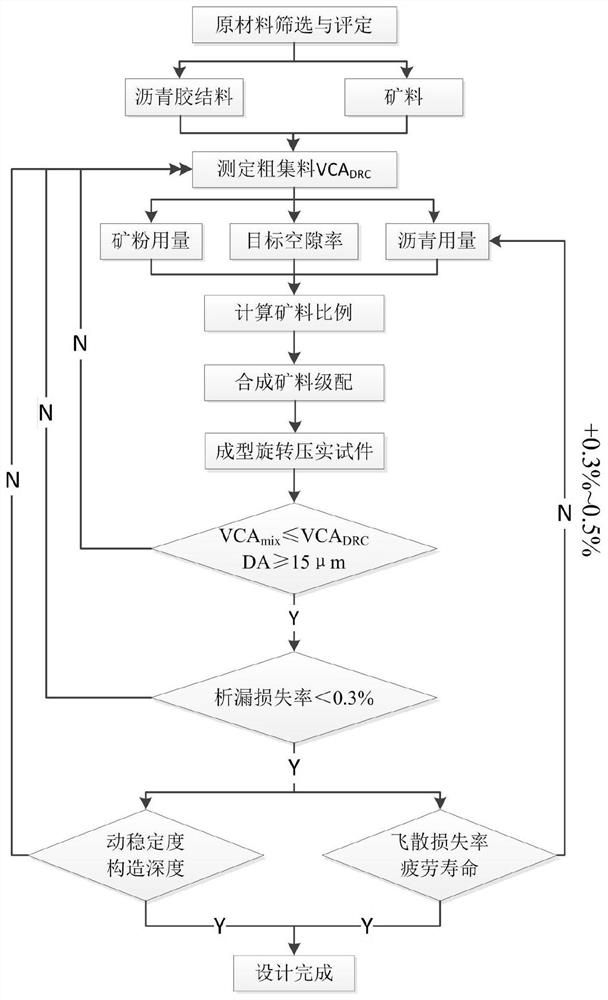

[0098] The flow chart of GT-8 gradation design process of high toughness ultra-thin asphalt wear layer is as follows: figure 1 As shown, the steps are as follows:

[0099] 1. Conduct conventional asphalt performance testing and rheological performance testing on high-viscosity and high-elasticity modified asphalt. The test results are shown in Table 2:

[0100] Table 2 Performance test results and technical requirements of high-viscosity and high-elasticity modified asphalt

[0101]

[0102] The screening results of the diabase used in this gradation design are shown in Table 3:

[0103] Table 3 Screening results of mineral materials of various specifications

[0104]

[0105]

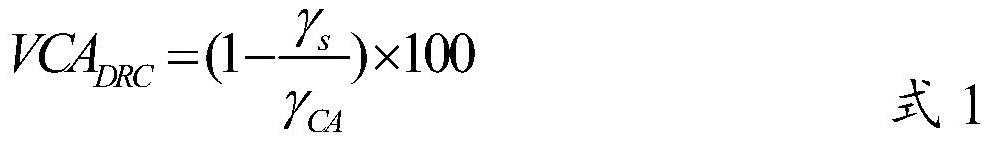

[0106] 2. Coarse aggregate specifications are divided into 3-5mm specification materials and 5-8mm specification materials. Adjust the admixture ratio between the two grades of coarse aggregate to 3~5:5~8=1:3, and use the dry pounding method to test that the compact density of the coarse ag...

Embodiment 2

[0125] The GT-5 gradation design process of high-toughness ultra-thin asphalt wear layer, the steps are as follows:

[0126] 1. Conduct conventional asphalt performance testing and rheological performance testing on high-viscosity and high-elasticity modified asphalt. The test results are shown in Table 5:

[0127] Table 5 Performance test results and technical requirements of high-viscosity and high-elasticity modified asphalt

[0128]

[0129] The screening results of the diabase used in this gradation design are shown in Table 6:

[0130] Table 6 Screening results of mineral materials of various specifications

[0131]

[0132] 2. The tight packing density of coarse aggregate is 1.81g / cm2 by dry pounding test 3 , combined with the aggregate density to calculate the coarse aggregate void ratio VCA DRC . The result of the calculation is VCA DRC = 38.5%.

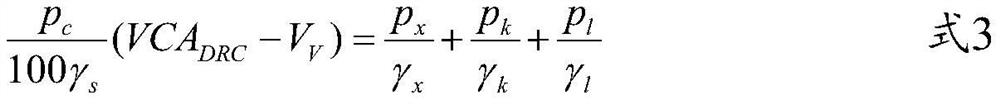

[0133] 3. Preliminarily set the amount of asphalt to 6.98% (that is, the asphalt ratio is 7.5%), the amount of m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com