Method for attaching upper casing to gasket

A gasket and casing technology, which is applied to the pasting field of the upper casing and the gasket, can solve the problems of damage, destruction and high cost of the press head, and achieve improved production efficiency, stable transition time, and single-step operation specifications. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] The pasting method for the upper casing and the gasket includes the following steps:

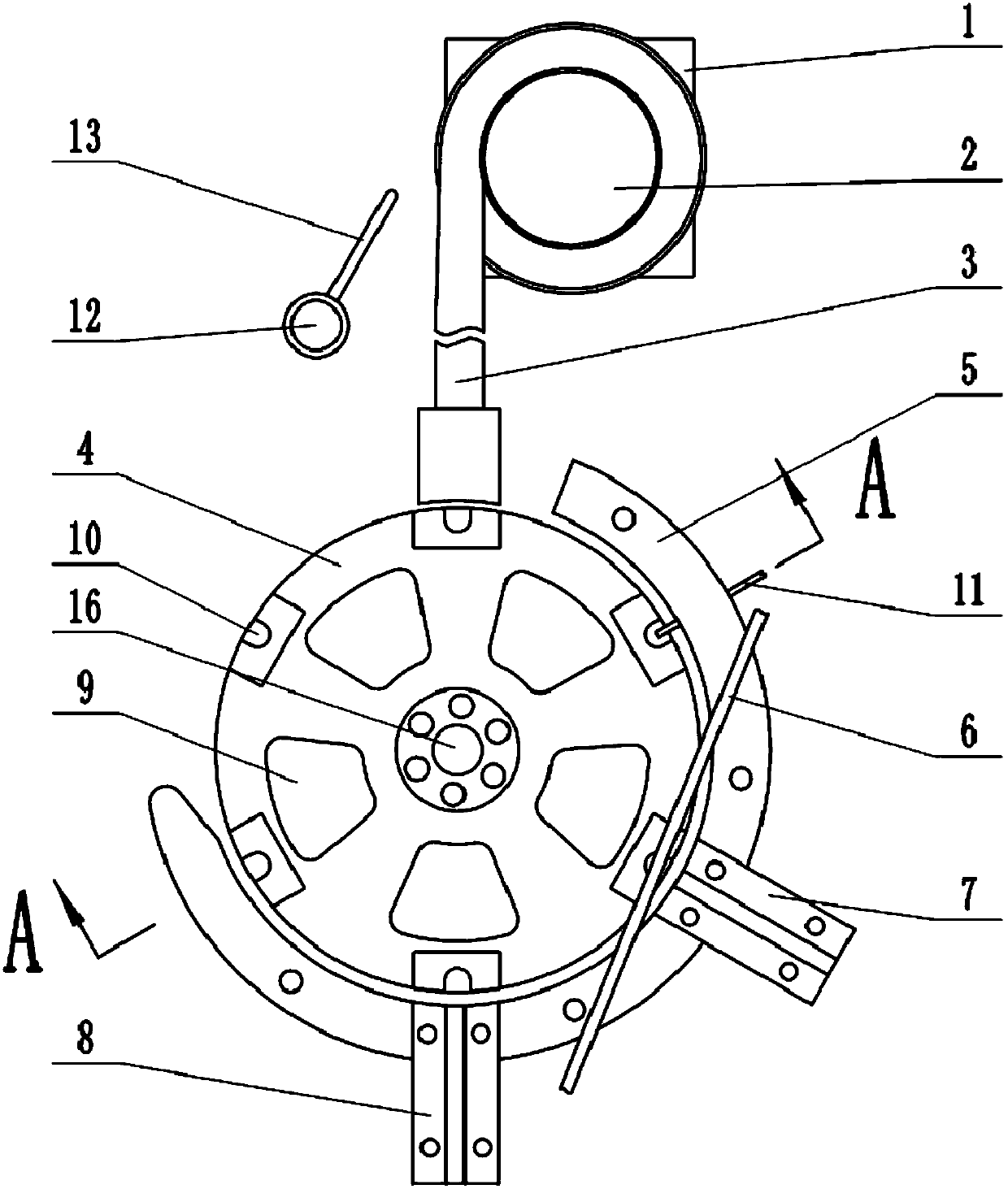

[0035] The first step, equipment preparation, basically as attached figure 1 Shown: the automatic feeding device, the indexing plate 4, the detection device, the press 8, the tape transport device for automatically providing the gasket and the gasket separator 7 that will be used when preparing to paste the gasket, so that the automatic feeding device The casing vibrating feeding tray 2 is connected with the indexing tray 4, so that the casing vibrating feeding tray 2 can transport the upper casing to the position of the indexing tray 4; 7 and press 8 are installed around the index plate 4.

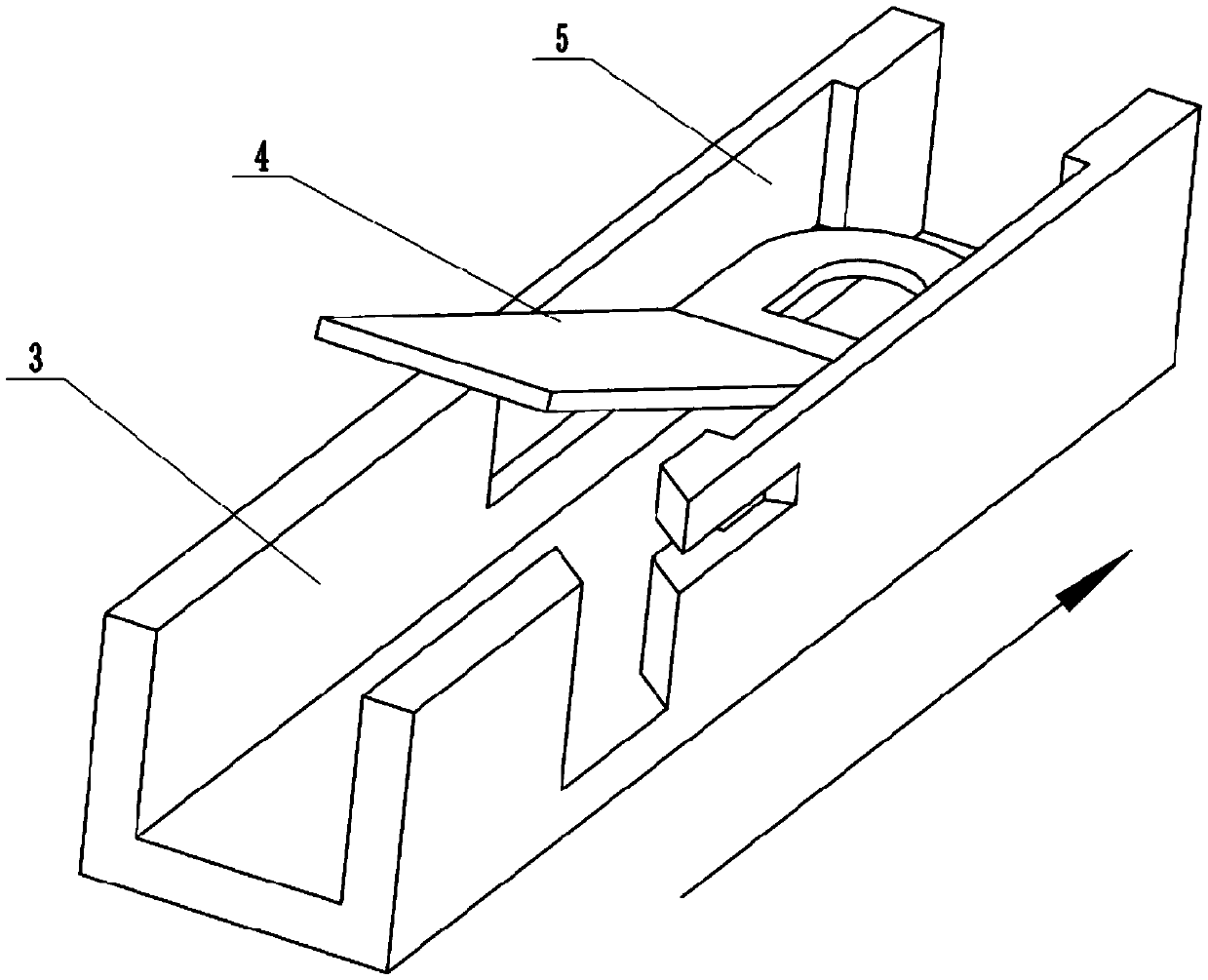

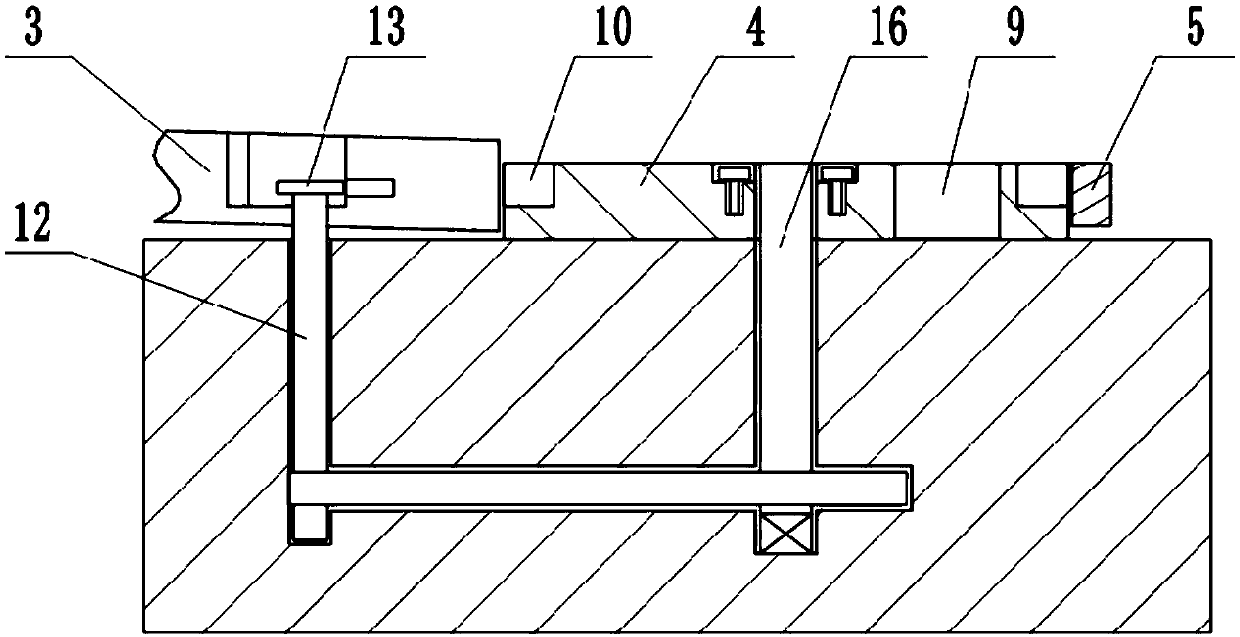

[0036] The specific structure of the equipment is as follows: it includes a frame 1, an indexing plate 4 and an automatic feeding device for transporting the upper casing to the position of the indexing plate 4, and the indexing plate 4 is provided with a casing accommodation cavity 10. In this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com