Thermosetting electrically conductive adhesive

A conductive and thermal curing technology, used in conductive adhesives, adhesives, modified epoxy resin adhesives, etc., to solve problems such as reducing connection resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10、 comparative example 1

[0078] In order to prepare the compositions of Examples 1-10 and Comparative Example 1, the following components were prepared.

[0079] (A) Component: curable resin

[0080] ・A urethane-modified oligomer having a (meth)acryloyl group, that is, an aromatic urethane acrylate having 6 functional groups (acryloyl groups) in the molecule (Ebecryl 220 manufactured by Daicel Allnex Co., Ltd.)

[0081] ・2-Hydroxyethyl methacrylate (HEMA Nippon Shokubai Co., Ltd.)

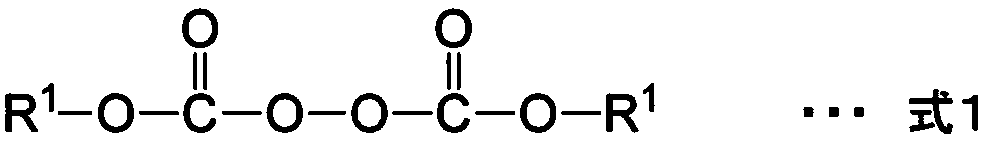

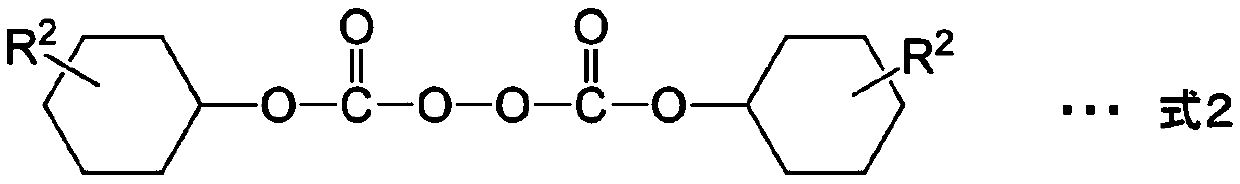

[0082] (B) component: heat curing agent that cures (A) component

[0083] ・Bis(4-tert-butylcyclohexyl)peroxydicarbonate (solid at 25°C) (Peroyl TCP, manufactured by NOF Corporation) (a type of organic peroxide having the structure of the above general formula 2)

[0084] (C) Ingredient: organometallic complex

[0085] ・Zinc acetylacetonate (divalent) (manufactured by NāCEM Zinc Nippon Chemical Industry Co., Ltd.)

[0086] ・Aluminum acetylacetonate (trivalent) (manufactured by Aluminum Nippon Kagaku Sangyo Co., Ltd.)

...

Embodiment 11~14、 comparative example 2~3

[0124] In order to prepare the compositions of Examples 11-14 and Comparative Examples 2-3, the following components were prepared.

[0125] (A) Component: curable resin

[0126] ・3-Ethyl-3phenoxymethyloxetane (Aron Oxetane OXT-211 manufactured by Toagosei Co., Ltd.)

[0127] ・3-Ethyl-3{[(3-ethyloxetan-3-yl)methoxy]methyl}oxetane (AronOxetane OXT-221 manufactured by Toagosei Co., Ltd.)

[0128] ・Multifunctional alicyclic epoxy group-containing silicone oligomer (X-40-2670 Shin-Etsu Chemical Co., Ltd.)

[0129] ・3',4'-Epoxycyclohexylmethyl-3,4-epoxycyclohexanecarboxylate (Ceroxide 2021P manufactured by Daicel Co., Ltd.)

[0130] ・Glycidylamine epoxy resin (EP-3950S manufactured by ADEKA Co., Ltd.)

[0131] ・Bisphenol F type epoxy resin (manufactured by EPICLON EXA-835LV DIC Co., Ltd.)

[0132] ・p-tert-butylphenyl glycidyl ether (manufactured by EPIOL TB NOF Corporation)

[0133] ・Glycidyl neodecanoate (manufactured by CARDURAE10P MOMENTIVE)

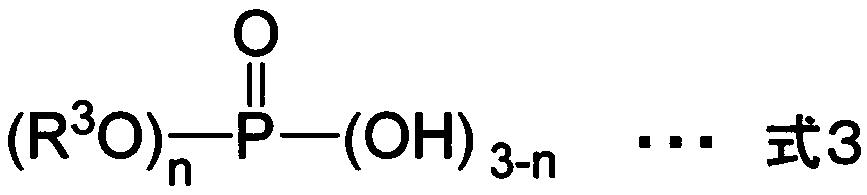

[0134] (B) component: heat cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com