Spraying device suitable for small batch detection

A spraying device and small-batch technology, applied in spraying devices, liquid spraying devices, etc., can solve the problems of more minimum liquid storage requirements, paint waste, environmental pollution, etc., to reduce waste, reduce environmental impact, and improve work efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

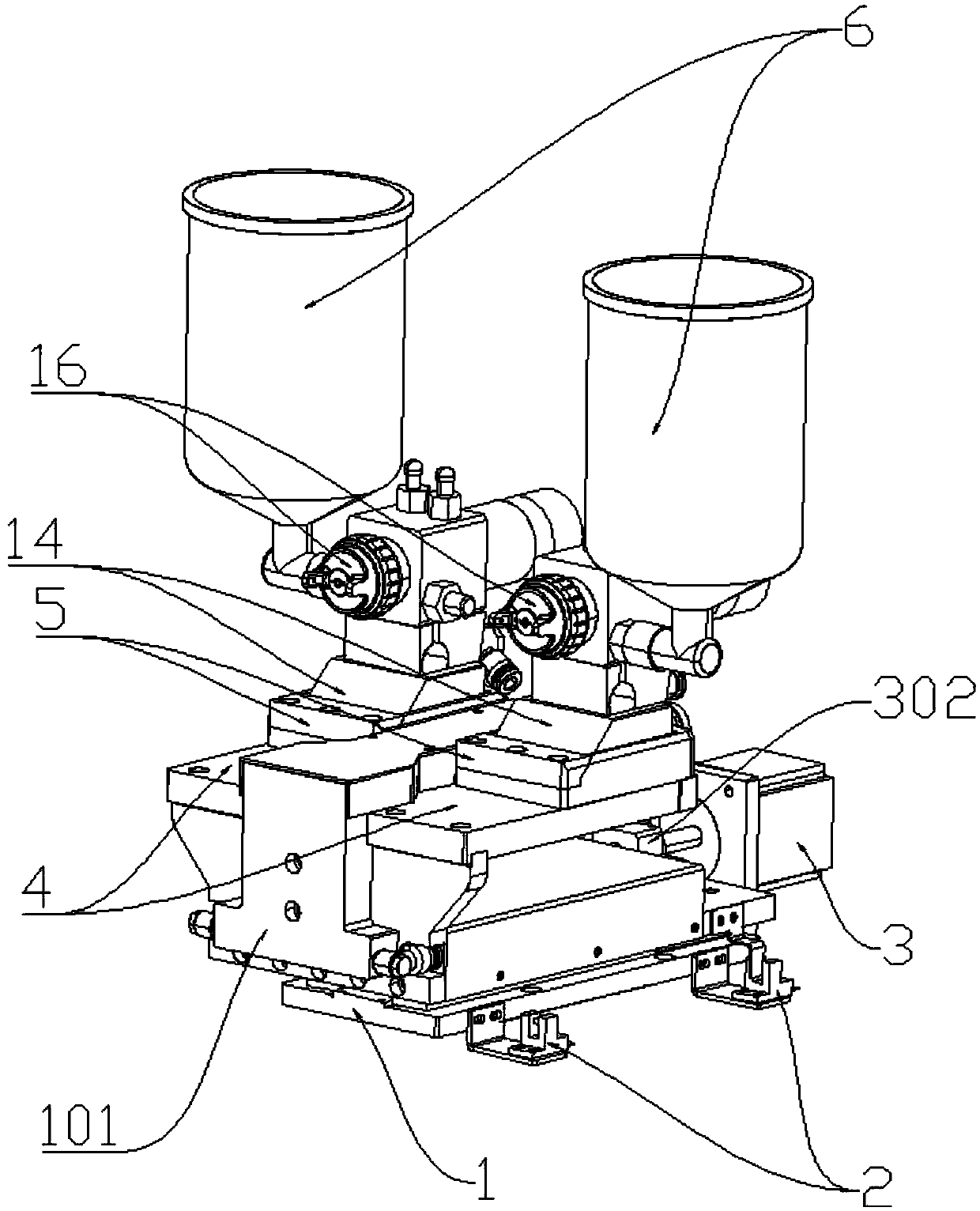

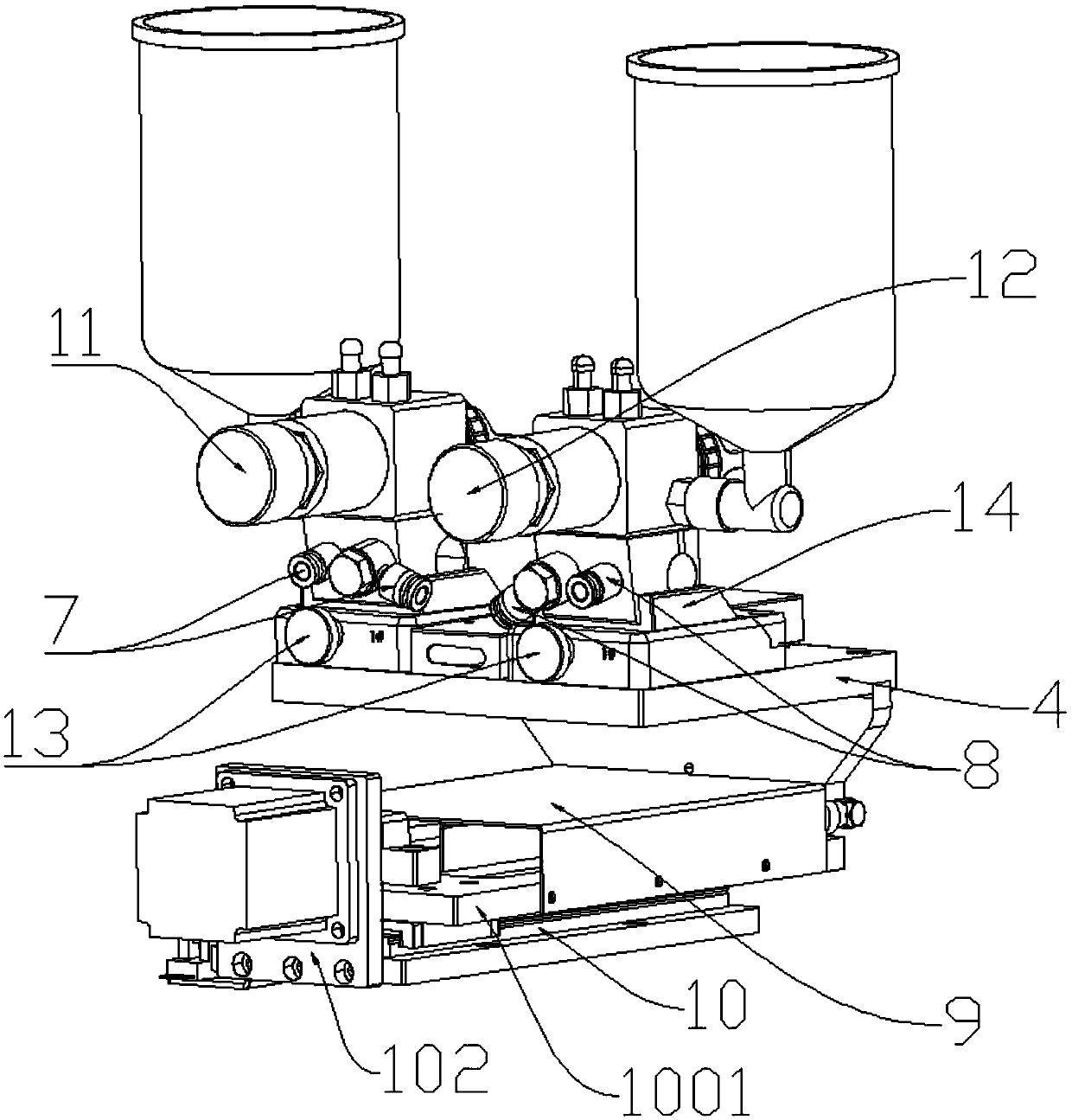

[0025] The device is fixed on the working platform through two rows of mounting holes on the base 1; the device controls the position of the spray gun platform to control the servo motor 3 to drive the moving screw 301 to rotate, thereby driving the moving seat 1001 to slide on the moving guide rail 10. When sliding, The limit positions on both sides are realized by two spray gun platform position sensors 2 and the position sensing frame 201. When the position sensor frame 201 on the moving seat 1001 moves to the spray gun platform position sensor 2, the command is triggered, so that the host computer moves toward the spray gun platform. The position control servo motor 3 sends an instruction to stop the motion.

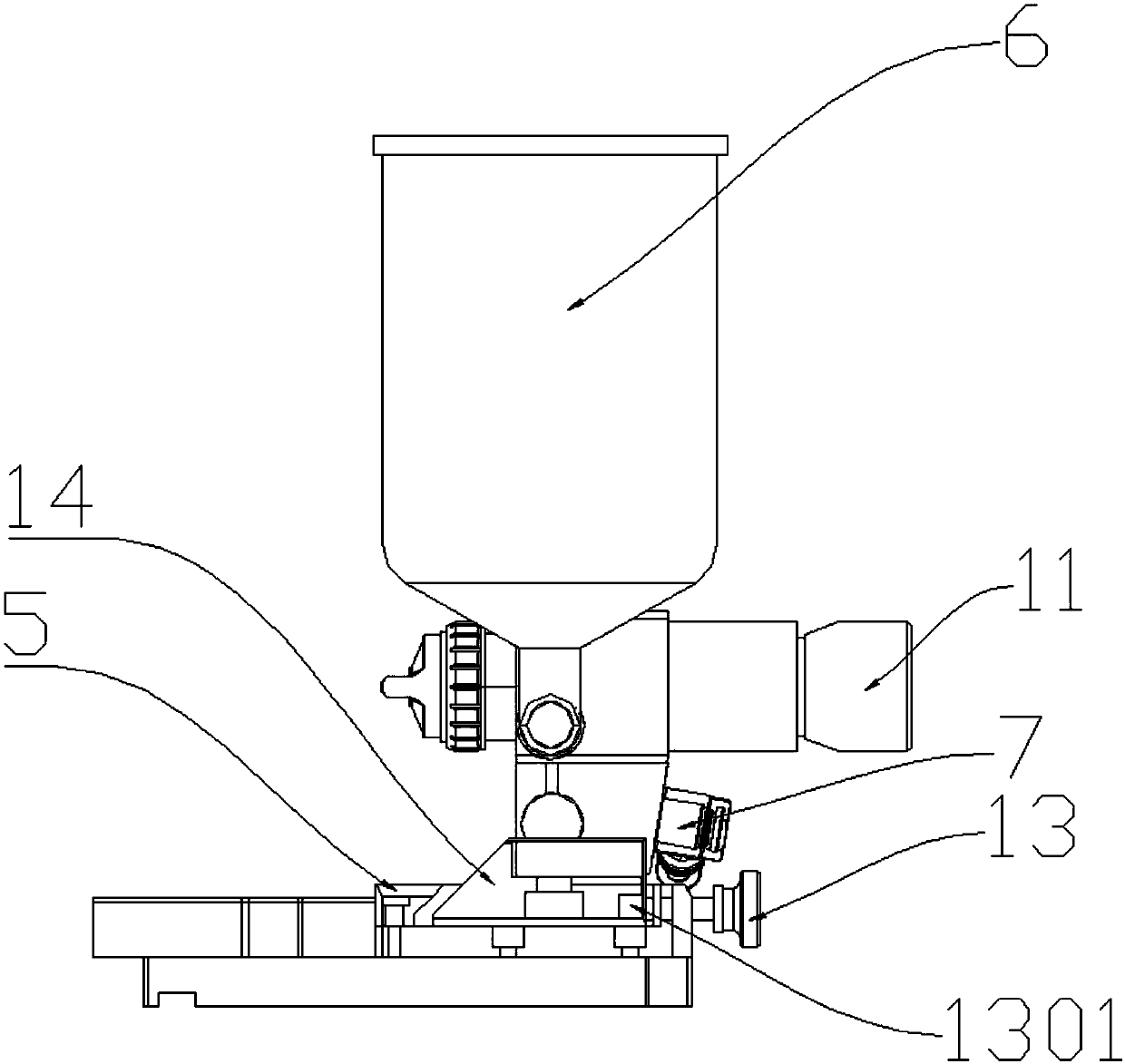

[0026] When the spraying gun needs to be replaced, first unscrew the labor-saving hand-tightened bolt 13, so that the spraying gun fixing fixture 14 is separated from the spraying gun fixing fixture protector 5, thereby realizing quick replacement of the spraying gun;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com