Energy-saving cold-accumulated-type refrigerating compartment

A technology of cold storage and cold storage tank, which is applied to the transportation of refrigerated goods, household refrigeration devices, heating/cooling equipment, etc., can solve the problems of increasing the fuel consumption or power consumption of vehicles, unable to refrigerate products, and reducing the cruising range of transport vehicles, so as to improve the cruising range. The effect of reducing mileage and fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

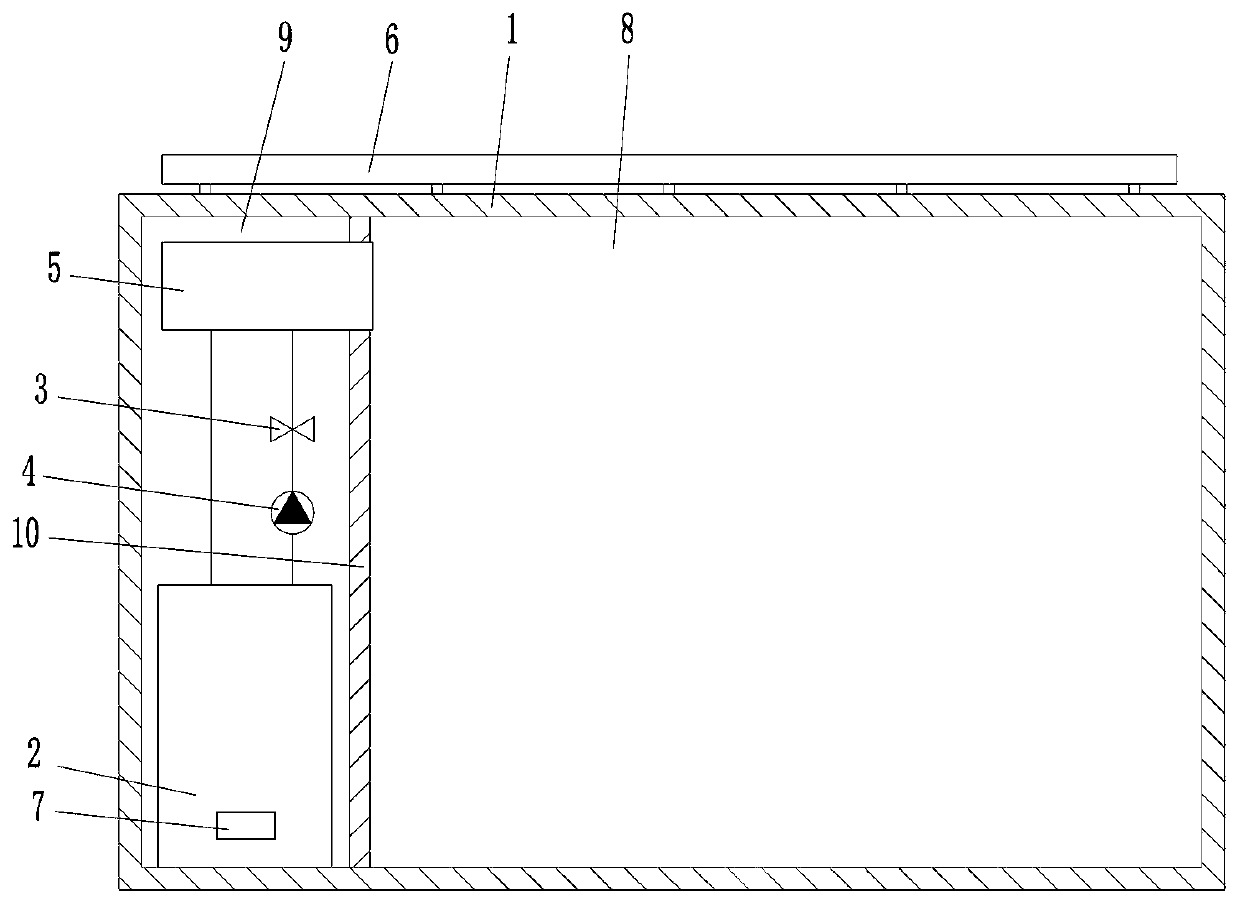

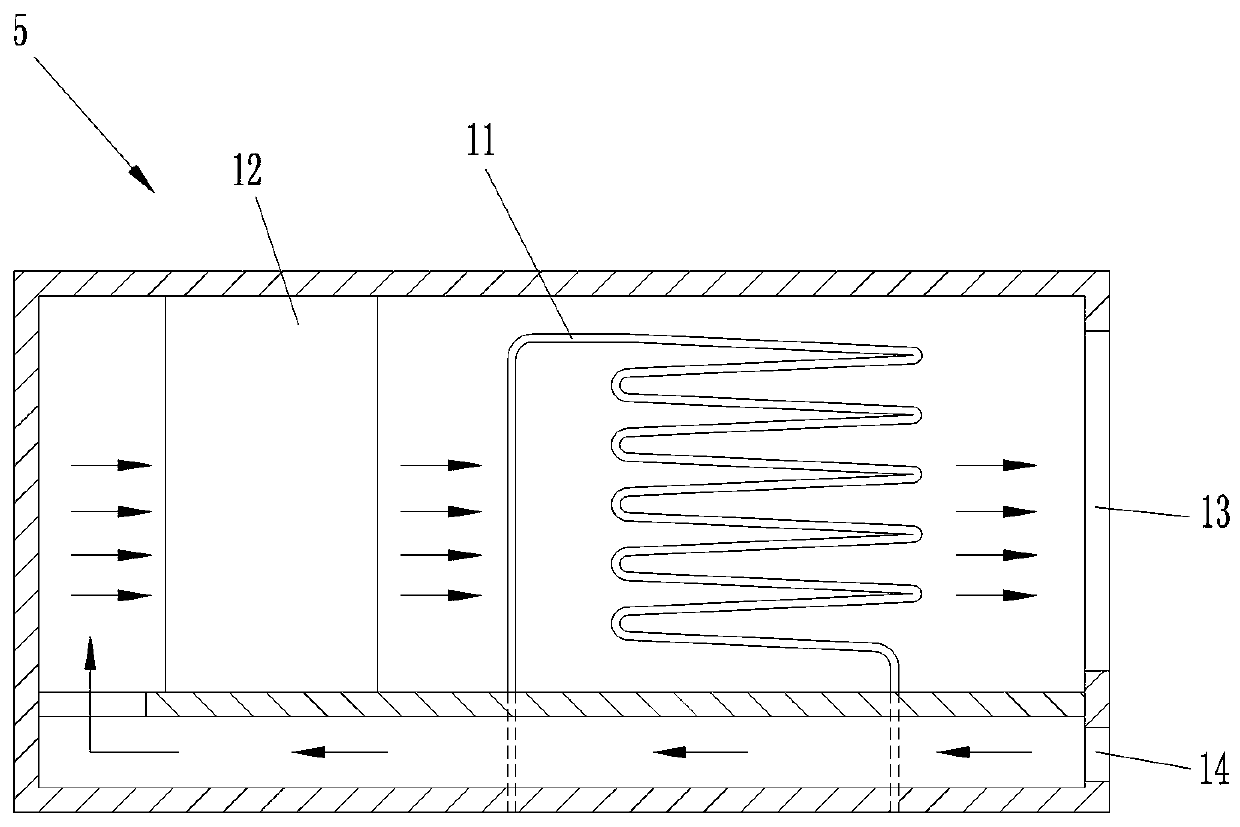

[0020] Such as figure 1 As shown, a kind of energy-saving cool-storage refrigerated compartment 1 comprises a refrigerated compartment 1, a cool-storage tank 2 filled with a cool-storage agent, a shut-off valve 3, a circulating pump 4 for extracting the cool-storage agent in the cool-storage tank 2, and the extracted cool-storage agent The heat exchanger 5 for heat exchange, the temperature sensor that senses the temperature in the refrigerated compartment 1 , the control system that receives the signal from the temperature sensor and controls the operation of the circulation pump 4 , and the solar panel 6 located on the top of the refrigerated compartment 1 . The cold storage agent in the cold storage tank 2 passes through the circulation pump 4, the shut-off valve 3, and the heat exchanger 5 and returns to the cold storage tank 2. The cold storage tank 2 is provided with a low-temperature cold charging connector 7, which can be connected to the cold storage tank when the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com