Device and method for preparing ammonium molybdate from molybdic acid

A technology of ammonium molybdate and ammonium tetramolybdate, which is applied to the preparation of molybdenum compounds, chemical instruments and methods, and molybdenum compounds, can solve the problems of high energy consumption, low concentration of ammonium molybdate solution, and large consumption of ammonia water, etc., and achieve High economic value, reduced staff workload, and low processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

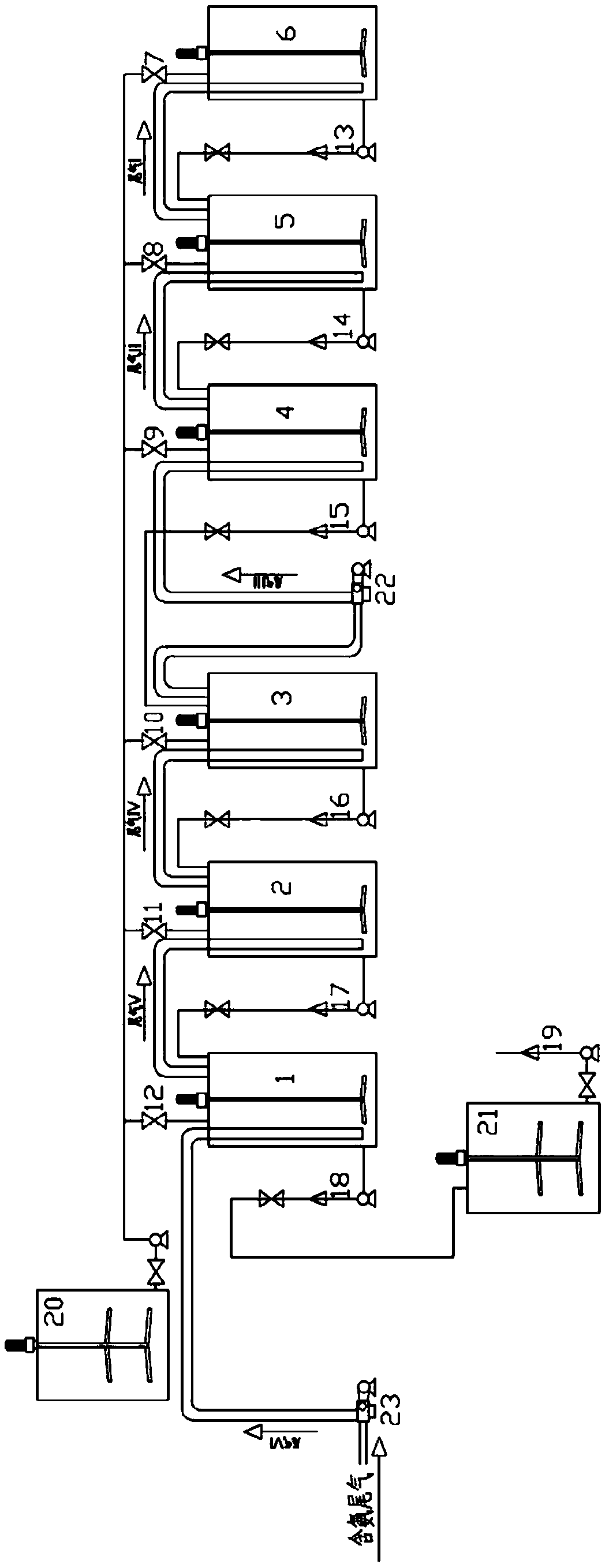

[0028] Such as figure 1 As shown, taking the six-stage countercurrent absorption and concentration device as an example, the present invention utilizes molybdic acid to prepare ammonium molybdate. 1. The inlet of molybdenum acid solution for adding molybdenum acid solution and the outlet of ammonium molybdate solution for discharging ammonium molybdate solution. The first-stage to fifth-stage absorption tanks are also equipped with tail gas outlets for discharging ammonia-containing tail gas and use Add the ammonium molybdate solution inlet of the ammonium molybdate solution, the exhaust gas outlet of the previous stage absorption tank is connected with the tail gas inlet of the rear stage absorption tank, the ammonium molybdate solution inlet of the previous stage absorption tank is connected with the rear stage absorption tank The ammonium molybdate solution outlet is connected.

[0029] Among them, in order to distinguish in name from the ammonium molybdate solution genera...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap