Adsorption preventive type screen process film capable of being peeled at high speed and method for preparing adsorption preventive type screen process film

An anti-adsorption, release film technology, applied in the direction of pressure-sensitive film/sheet, film/sheet release liner, film/sheet release coating, etc., can solve the problem of reducing yield or production efficiency, breakdown capacitance, Static accumulation and other problems to achieve the effect of increasing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

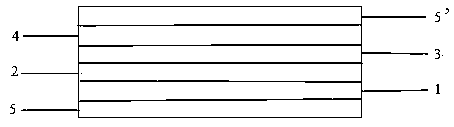

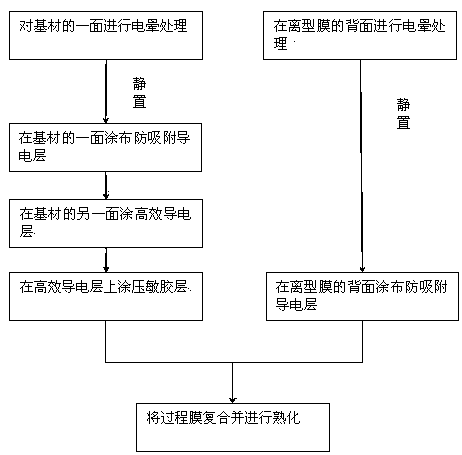

[0032] Such as figure 1 It is a schematic diagram of the structure of a high-speed tear-off anti-adsorption screen process film and figure 2 It is a high-speed tear-off anti-adsorption type screen process film production process schematic diagram, a high-speed tear-off anti-adsorption type screen process film production method, such as figure 1 , from bottom to top: anti-adsorption conductive layer one 5, base material 1, high-efficiency conductive layer 2, pressure-sensitive adhesive layer 3, release film 4 and anti-adsorption conductive layer two 5' constitute a layered product, and its preparation steps are as follows figure 2 Shown:

[0033] (a) Corona treatment is performed on both sides of the substrate 1 and the back of the release film 4, until the surface tension of the corona surface of the substrate 1 and the release film 4 is ≥ 48dyn, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com