Section steel column and construction method thereof

A technology of section steel and locking steel wire, applied in the direction of columns, piers, pillars, etc., can solve the problems of reducing the bearing capacity of section steel columns, affecting the bearing capacity of section steel, etc., to achieve convenient processing and construction, maintaining integrity, and convenient construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

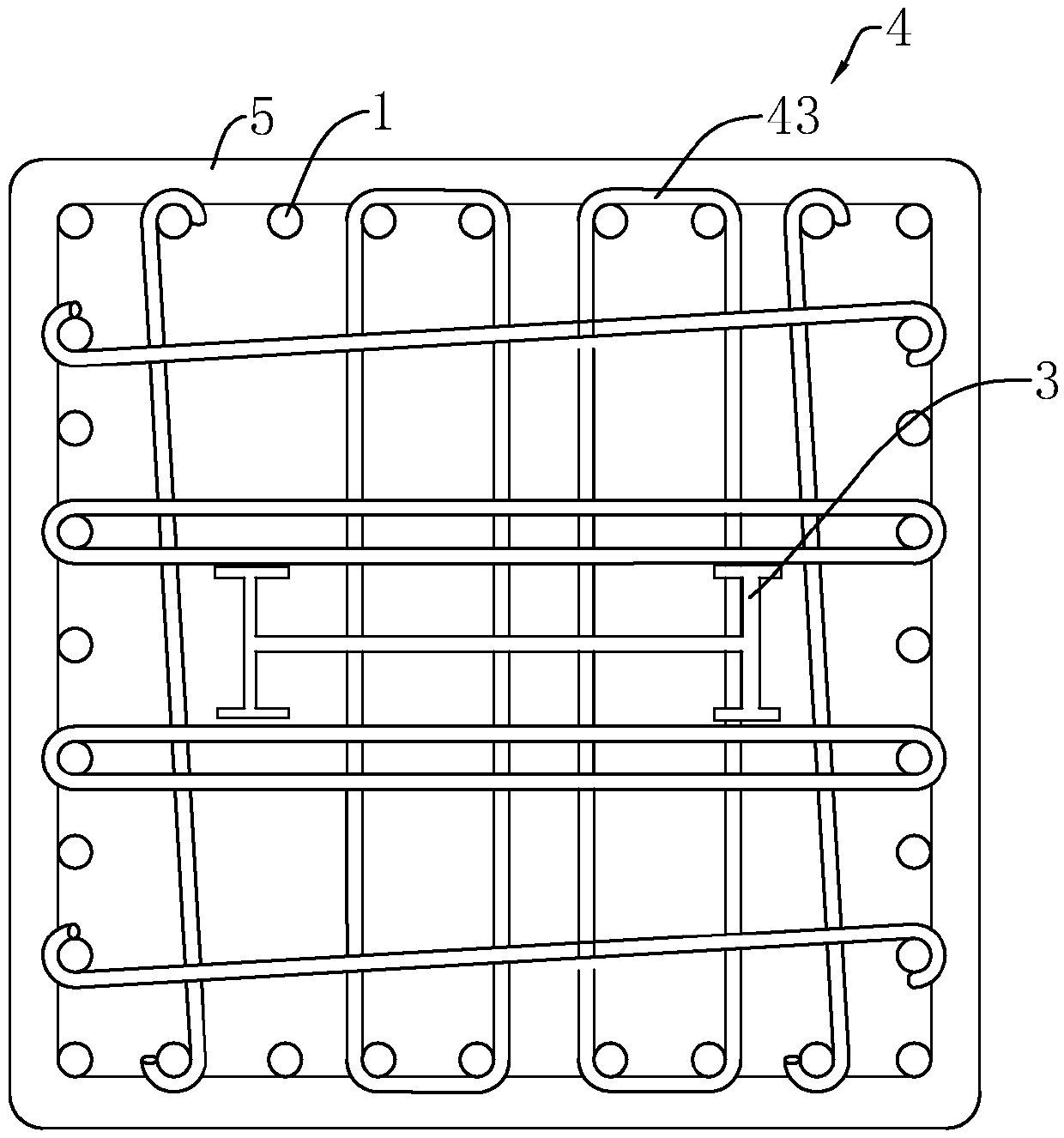

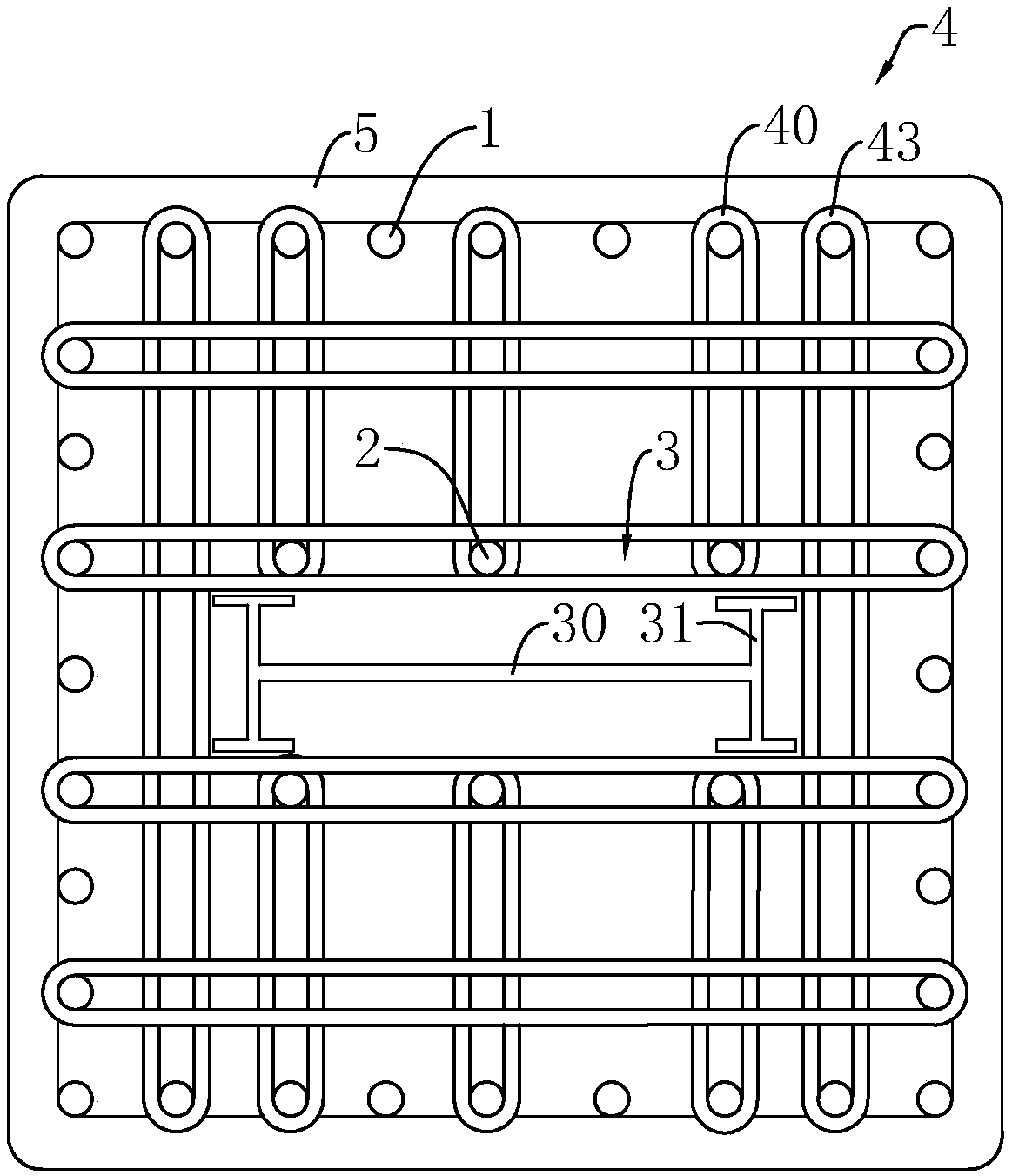

[0039] Embodiment 1, with reference to figure 2 , a shaped steel column includes shaped steel 3 , reinforcing longitudinal bars 1 , structural longitudinal bars 2 and connecting bars 4 .

[0040] refer to figure 2 , in the present embodiment, the shaped steel 3 is set and fixed at the center of the shaped steel column, the structural longitudinal bars 2 are fixed on both sides of the shaped steel 3, and there are vertically arranged reinforcing longitudinal bars 1 evenly distributed around the shaped steel 3, and the shaped steel 3 and the reinforced longitudinal bars 1 A connecting bar 4 is connected between the reinforcing longitudinal bars 1 facing inwardly in the gap. The connecting bar 4 includes a long stirrup 43 and a short stirrup 40. A long stirrup 43 is selected between two opposite reinforcing longitudinal bars 1. 43 has a fixing function between the reinforcing longitudinal bars 1, and increases the strength of the shaped steel column at the same time.

[0041]...

Embodiment 2

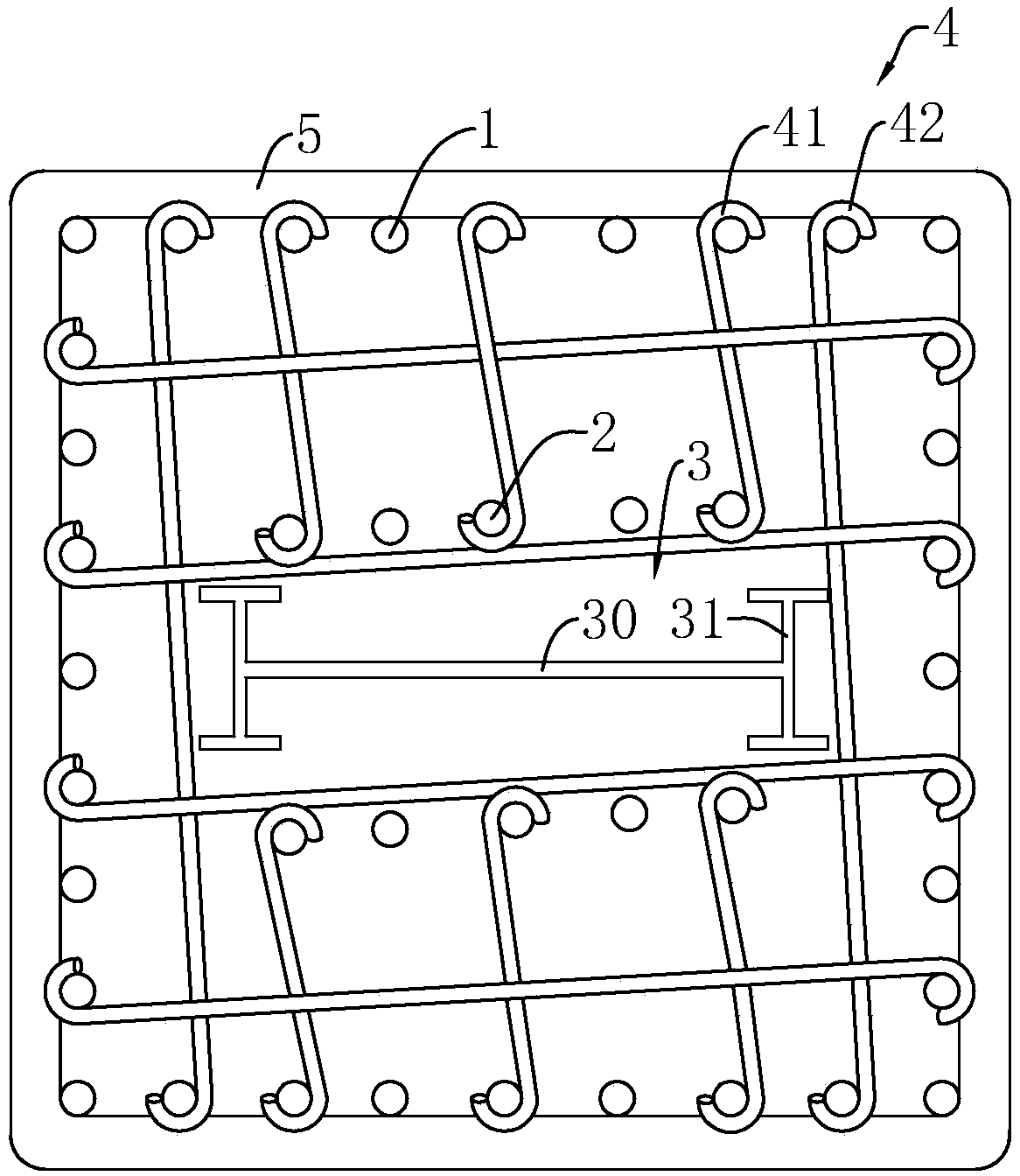

[0044] Embodiment 2, the difference between this embodiment and embodiment 1 is: refer to image 3 , the connecting rib 4 between two opposite reinforcing longitudinal bars 1 is a long tie bar 42, and the connecting bar 4 connected between the structural longitudinal bar 2 and the reinforcing longitudinal bar 1 is an end tie bar.

[0045] A construction method of a shaped steel column, comprising the following steps: A construction method of a shaped steel column, characterized in that: comprising the following steps:

[0046] S1: Stand the section steel 3 vertically at the preset position, as follows:

[0047] Stand the section steel 3 in the column foundation and fix it with concrete.

[0048] S2: Stand the structural longitudinal reinforcement 2 on the outside of the section steel 3, as follows:

[0049] Paste the structural longitudinal reinforcement 2 on both sides of the section steel 3 and fix it in the column foundation.

[0050] S3: Stand the reinforcing longitudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com