A Hybrid Control Synchronous Valve

A hybrid control and synchronous valve technology, applied in control valves, multi-way valves, balance valves, etc., can solve the problem of low synchronization accuracy of synchronous valves, achieve the effects of reducing outflow, improving control accuracy, and improving synchronization accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

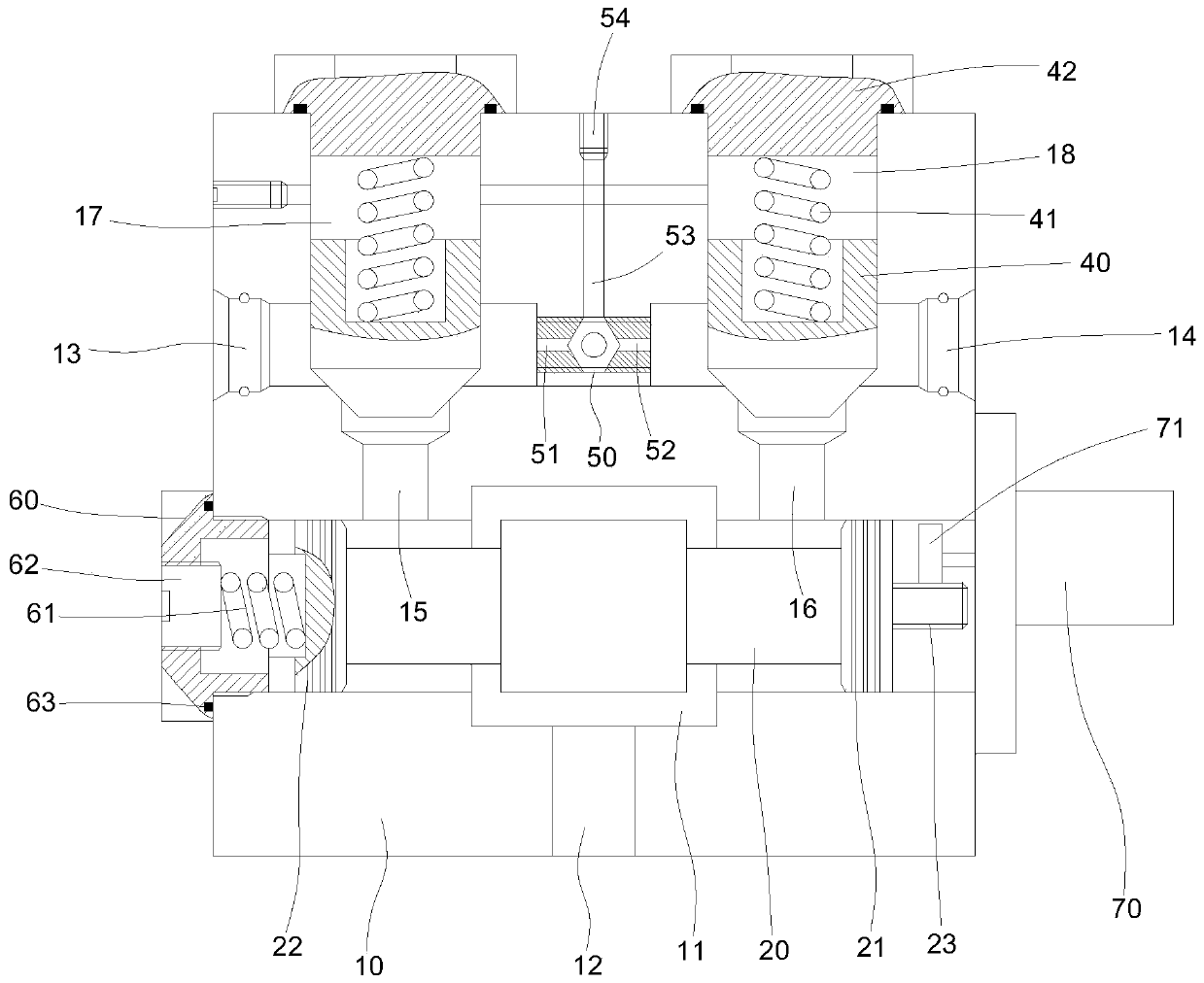

[0021] Please refer to figure 1 , a mixing control synchronous valve, including a valve body 10, the lower part of the valve body 10 is provided with an oil inlet chamber 11, the oil inlet chamber 11 is provided with a main valve core 20, and the valve body 10 is provided with an oil inlet port under the oil inlet chamber 11 12. The valve body 10 is provided with a left oil outlet 13 and a right oil outlet 14 on both sides of the upper part respectively, the left oil outlet 13 communicates with the oil inlet chamber 11 through the left passage 15, and the right oil outlet 14 passes through the right passage 16 It communicates with the oil inlet chamber 11, and the valve body 10 is provided with a left oil chamber 17 above the left passage 15, and a right oil chamber 18 above the right passage 16;

[0022] The left oil chamber 17 and the right oil chamber 18 are provided with an oil outlet valve core 40; the left and right ends of the main valve core 20 are respectively provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com