Variable rigidity hydraulic damping shock absorber with self-adaptive variable damping function

A technology of hydraulic damping and variable damping, applied in the field of damping shock absorbers, can solve the problems that the spring cannot be changed, cannot be connected smoothly, and the transition is abrupt, and achieves the effect of good control, variable stiffness, and suppression of torsional vibration of the transmission system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

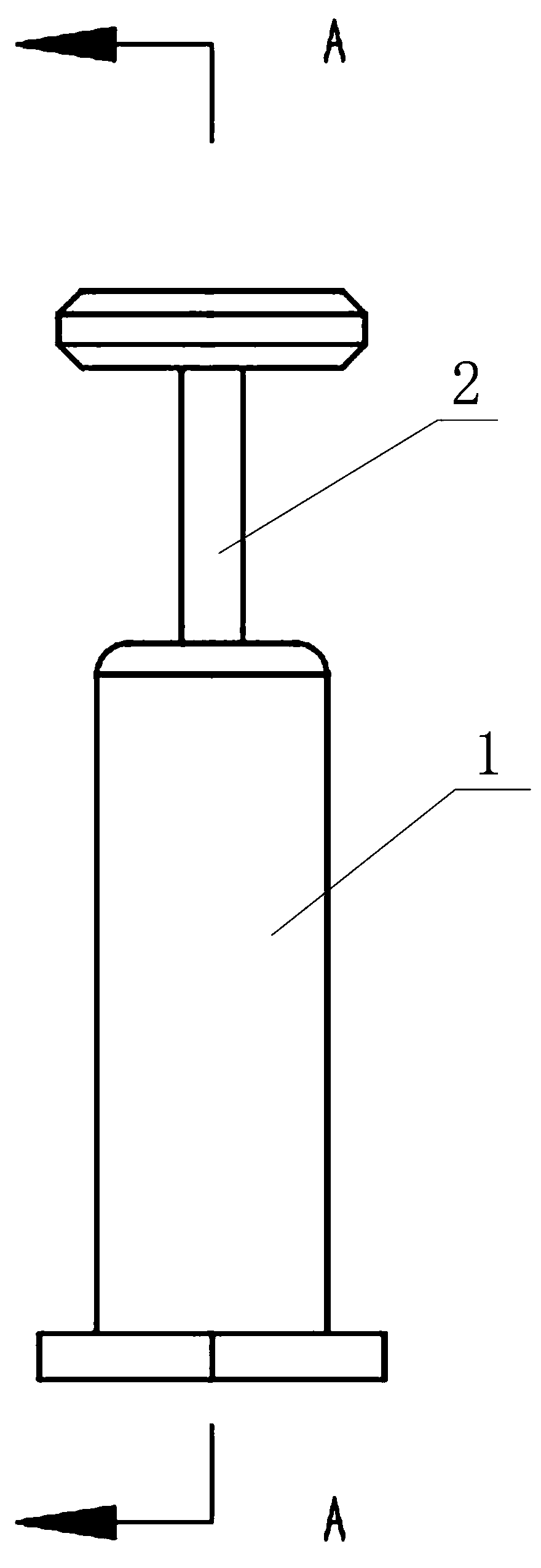

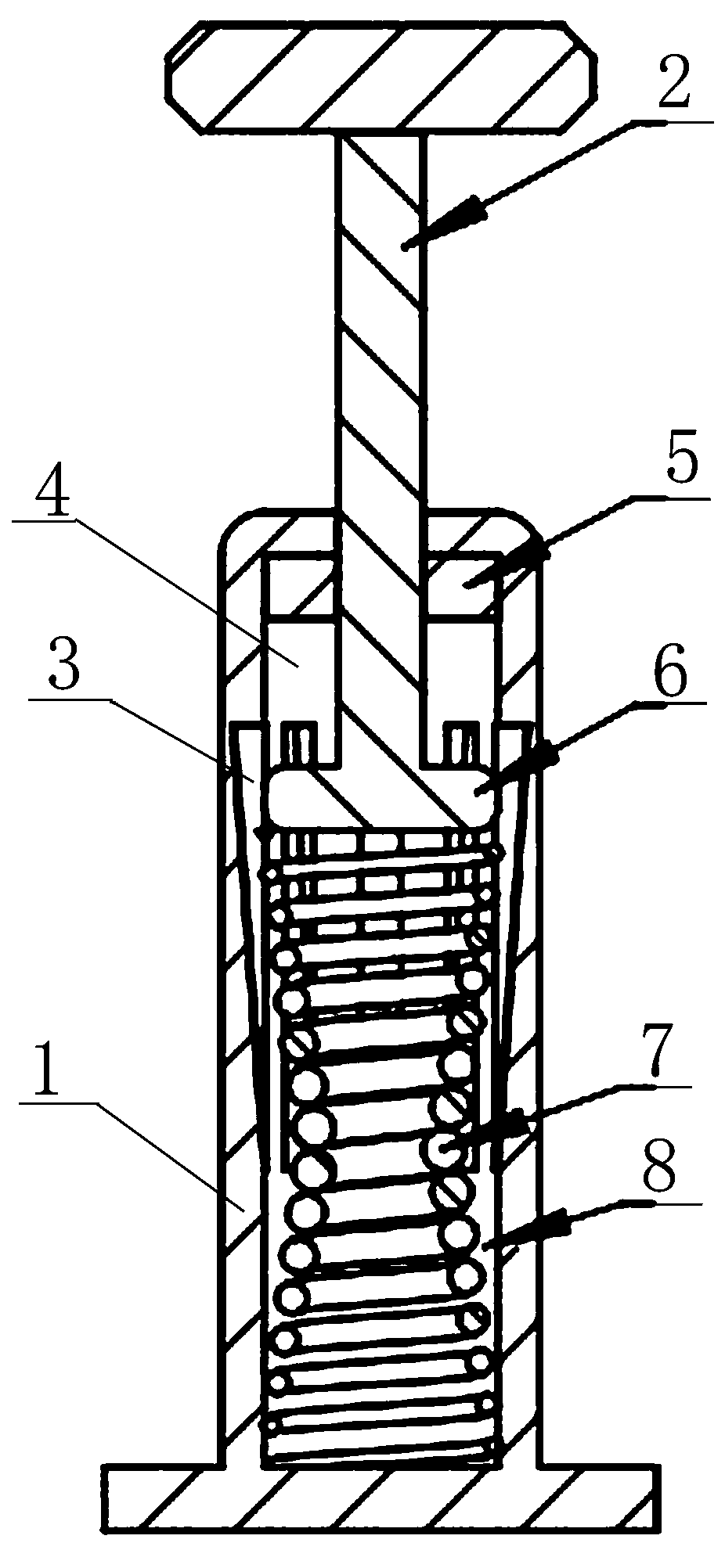

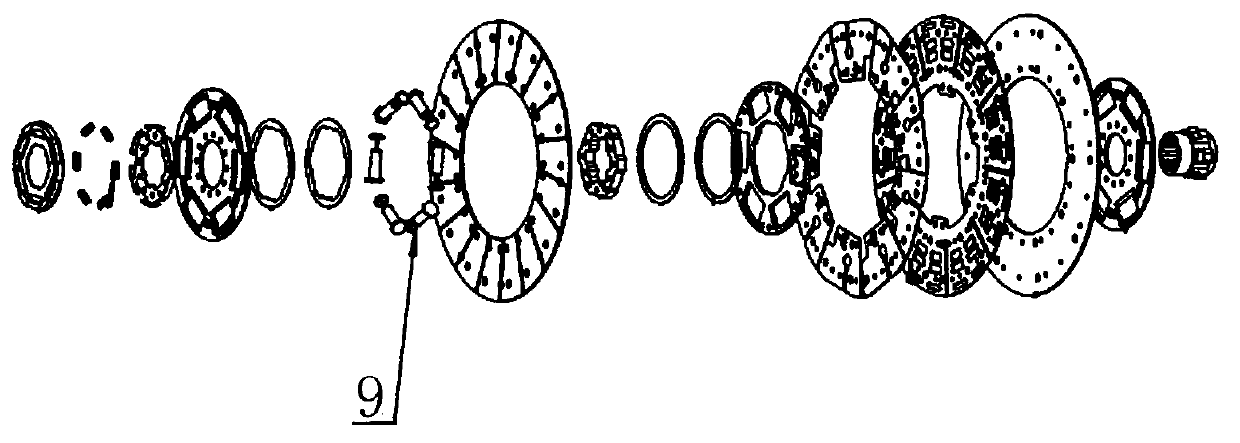

[0025] Such as figure 1 , figure 2 As shown, a hydraulic damping shock absorber with variable stiffness and adaptive variable damping includes a hydraulic cylinder block 1, a tappet 2, a floating piston 6, and a return spring 7; the floating piston 6 is arranged in the hydraulic cylinder block 1 Divide the inner cavity of the hydraulic cylinder 1 into an upper cavity 4 and a lower cavity 8, and make a sealing sliding fit with the inner wall of the hydraulic cylinder 1; the lower end of the tappet 2 passes through the hydraulic cylinder 1 from the top of the hydraulic cylinder 1 It is fixedly connected with the floating piston 6 as a whole; the return spring 7 is arranged in the lower cavity 8, the upper end of the return spring 7 is connected with the floating piston 6, and the lower end is connected with the bottom of the lower cavity 8; the hydraulic cylinder body 1 There are several variable damping grooves 3 distributed circumferentially along the extension direction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com