A mechanical twisting platform based on the dual -bearing wheel module

A double eccentric, mechanical technology, applied in the direction of metal processing, etc., can solve the problems of increased cost, production, production, installation and maintenance of drilling spindle, etc., to achieve good torsional vibration effect, precise drilling and reaming, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following description and drawings illustrate specific embodiments of the invention sufficiently to enable those skilled in the art to practice them. Other embodiments may incorporate structural, logical, electrical, process, and other changes. The examples merely represent possible variations. Individual components and functions are optional unless explicitly required, and the order of operations may vary. Portions and features of some embodiments may be included in or substituted for those of other embodiments. The scope of embodiments of the present invention includes the full scope of the claims, and all available equivalents of the claims.

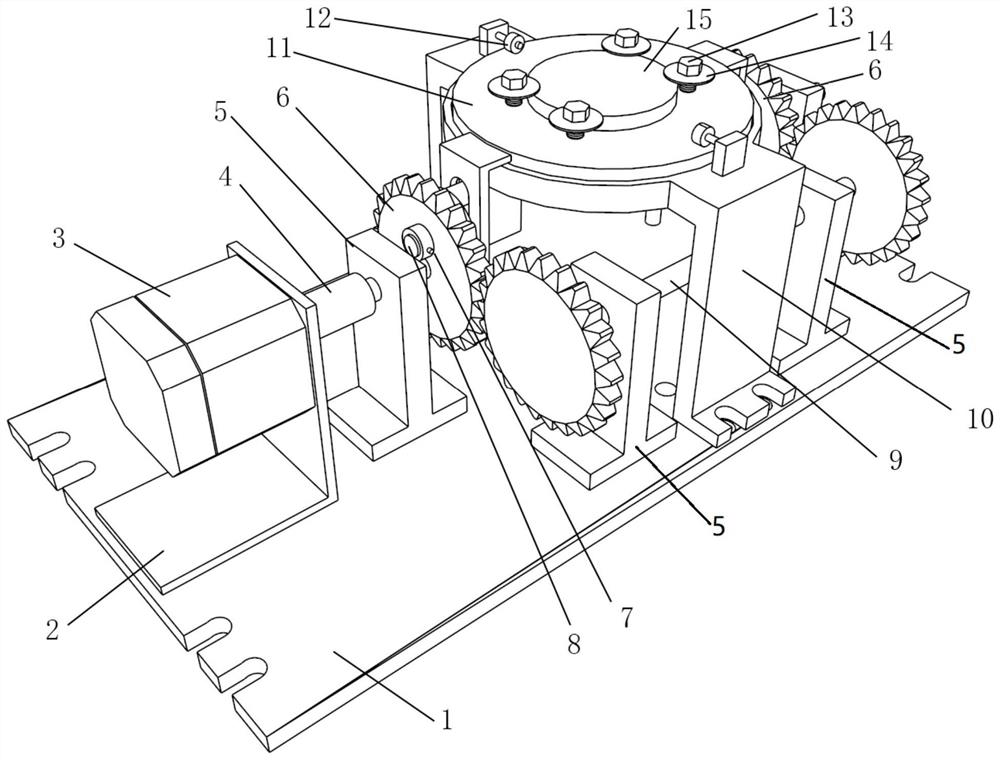

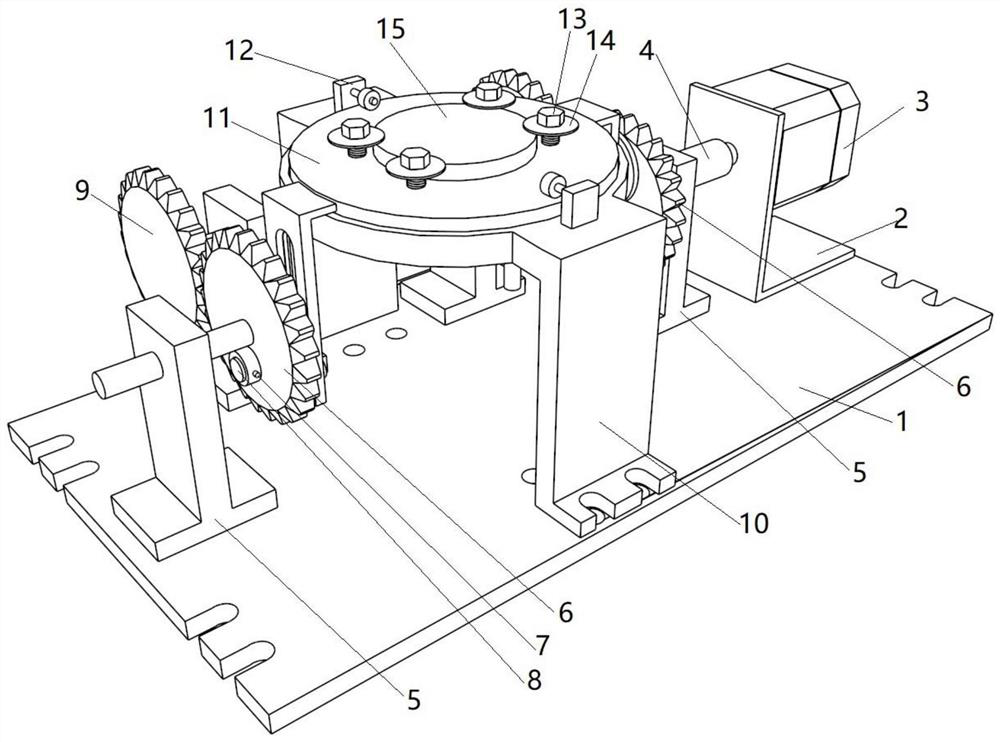

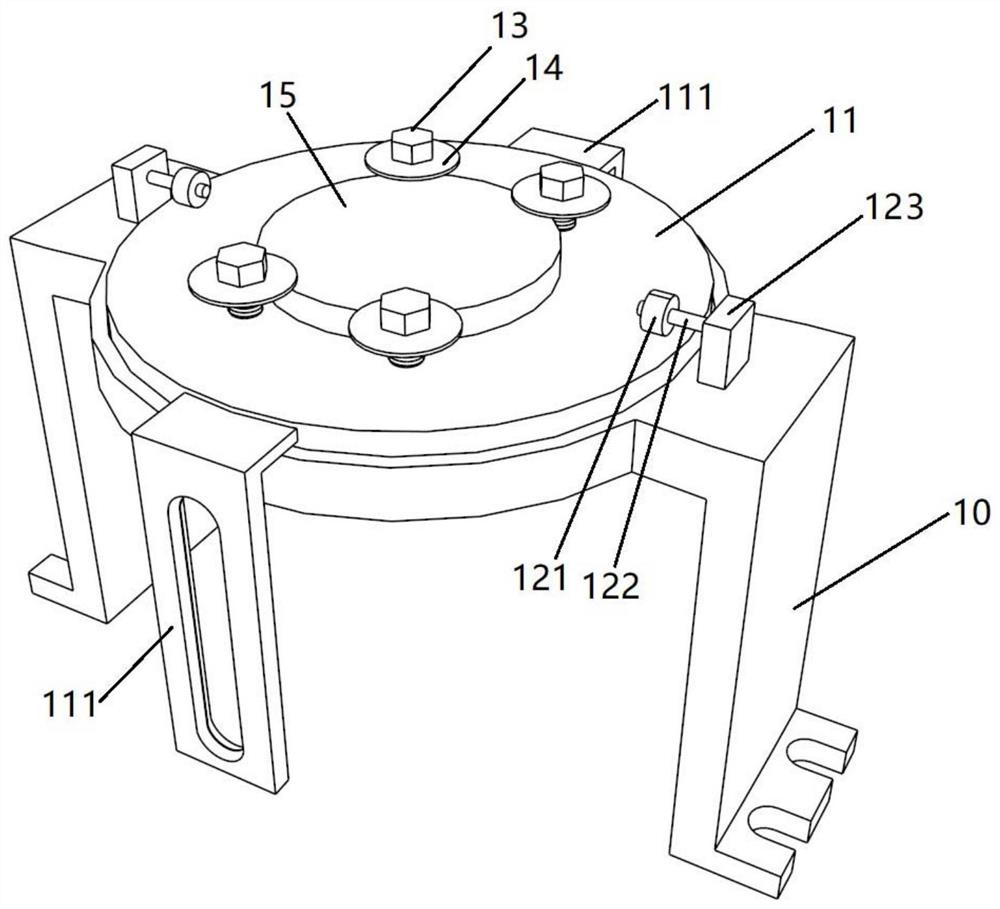

[0030] In some illustrative examples, such as Figure 1-10 As shown, a mechanical torsional vibration table based on a double eccentric wheel module, a servo motor bracket 2 is installed on an installation base plate 1, and a servo motor 3 is fixedly installed on the servo motor bracket 2. There are four rotating shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com