Ultrasonic torsional vibration measuring device and its measuring method

A technology of torsional vibration and measuring device, applied in measuring/indicating equipment, metal processing equipment, metal processing machinery parts, etc., can solve the problems of difficult measurement of related data, small torsional vibration, etc., to increase the amplification factor and enhance the longitudinal vibration. and torsional vibration effects, vibration modes and mode shapes are precisely controllable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

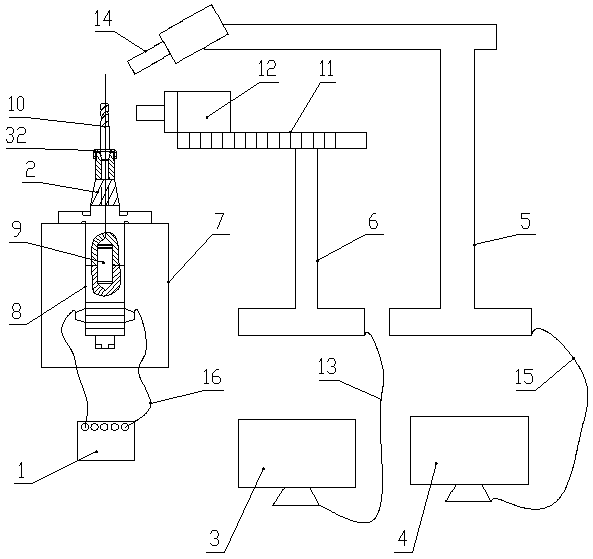

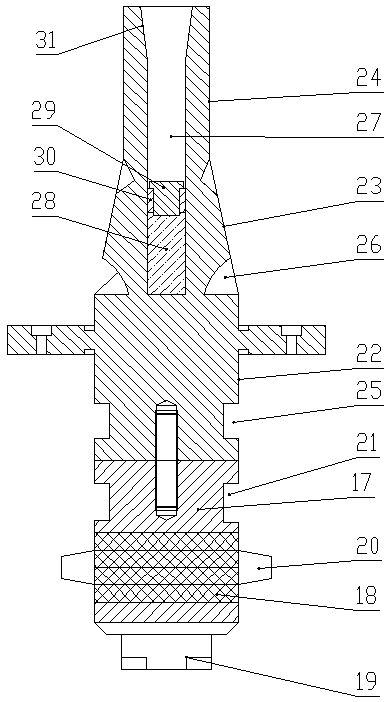

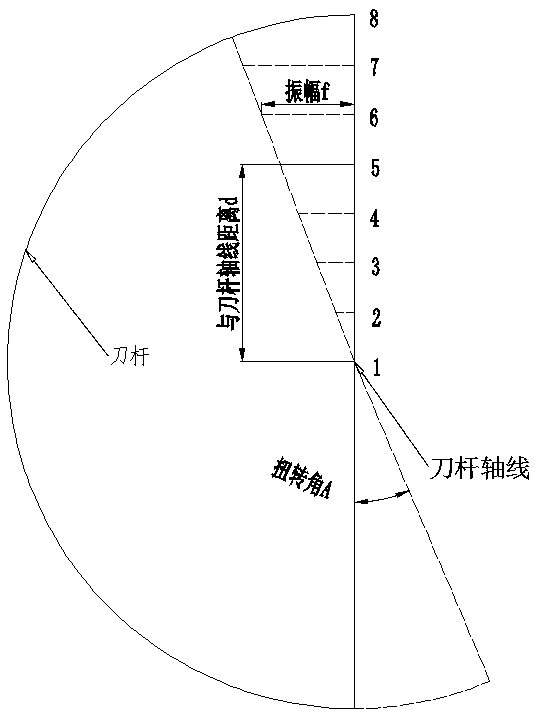

[0026] Such as figure 1 with figure 2 As shown, the ultrasonic torsional vibration measuring device of the present invention includes an ultrasonic power supply 1, a horn 2, a computer 3, a display 4, a first support 5, a second support 6 and a third support 7, and the third support 7 is provided with Transducer 8, the upper end of the transducer 8 is connected to the lower end of the horn 2 through the stud bolt 9, and the upper end of the horn 2 is connected with a standard cutter bar 10; the second bracket 6 is provided with a laser displacement sensor pan / tilt 11. Laser displacement sensor The cloud platform 11 is provided with a laser displacement sensor 12, the laser displacement sensor 12 is connected with the computer 3 through the first cable 13, the first bracket 5 is provided with a high-definition camera 14, and the high-definition camera 14 is connected to the computer through the second cable 15 The display 4 is connected; the ultrasonic power supply 1 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com