Extraction and back-extraction device

A kind of equipment and extraction technology, which is applied in the field of extraction and stripping equipment, can solve the problems of short mixing time, large organic phase volatilization, and large floor area, so as to achieve uncomplicated equipment structure, small organic phase volatilization, and small footprint Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

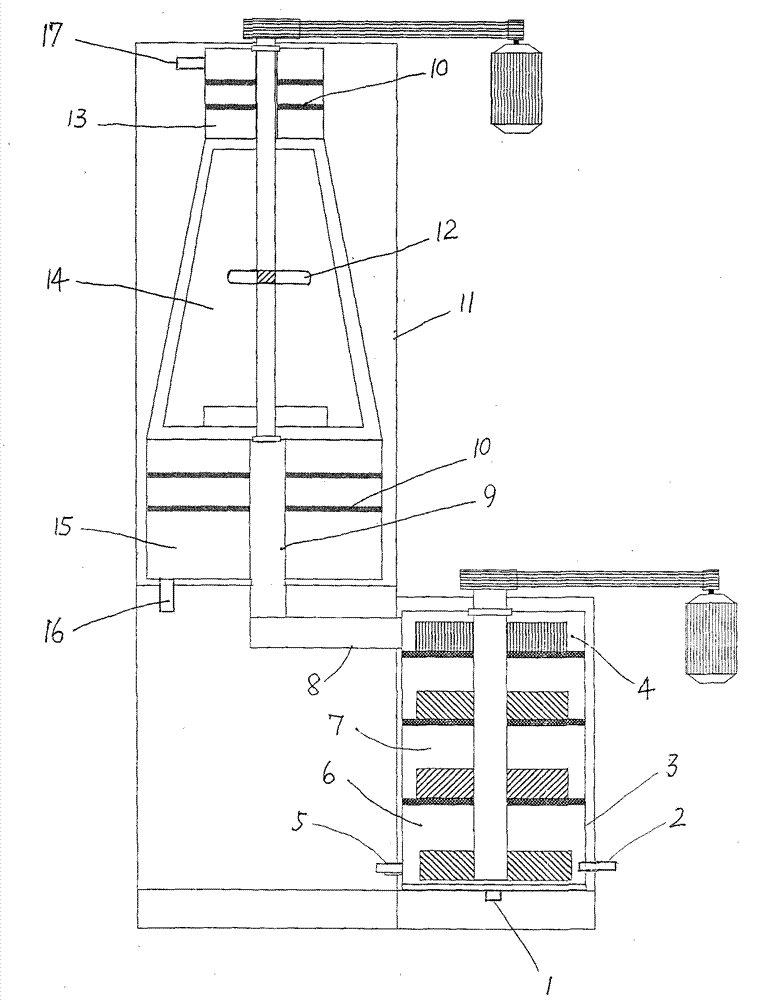

[0027] 1. Mixer

[0028] The mixer structure of the present embodiment is as figure 1 , which is composed of the first to third mixing chambers and the centrifugal chamber on the top layer, the mixer 3 realizes the efficient mixing of the organic phase and the water phase. According to the mixing time and the requirements of different media, the mixing times can be realized from 1 to 10 times and the corresponding 1 to 10 mixing chamber layers can be formed.

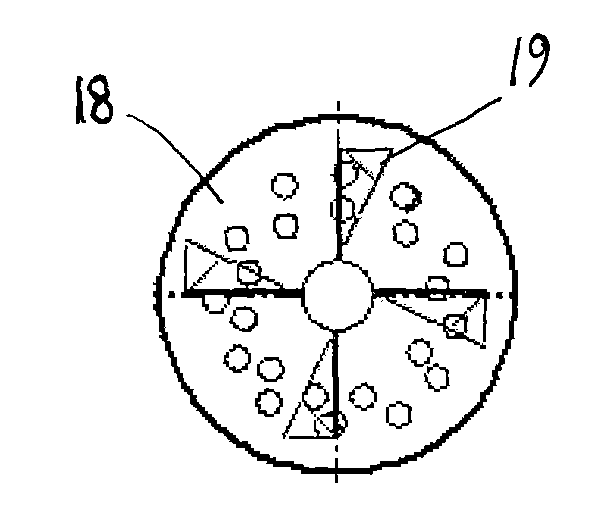

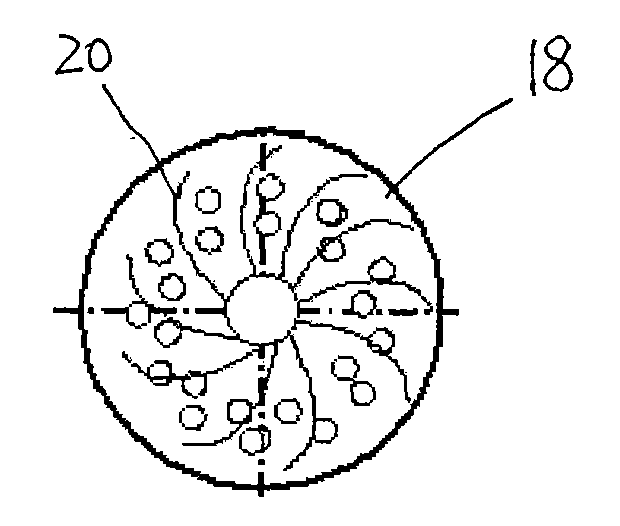

[0029] The organic phase and the water phase enter from the water phase inlet 5 and the organic phase inlet 2 on the bottom side of the mixer 3, or the bottom of the mixer, that is, the inspection port 1, which is basically the same as the organic phase and the water phase of the existing mixing clarifier. ; the bottom of the first stage mixing chamber 6, if it is the bottom inspection port inlet water phase and organic phase, then there is a disk 18 connected to the rotating shaft to prevent the organic phase and the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com