Water curtain type range hood

A range hood and range fume technology, which is applied in the direction of oil fume removal, heating methods, household heating, etc., can solve the problems of energy saving and oil removal, low adsorption efficiency, and poor adsorption effect without considering segmental operation, and achieve stability. properties, increase adsorption rate, and reduce saturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

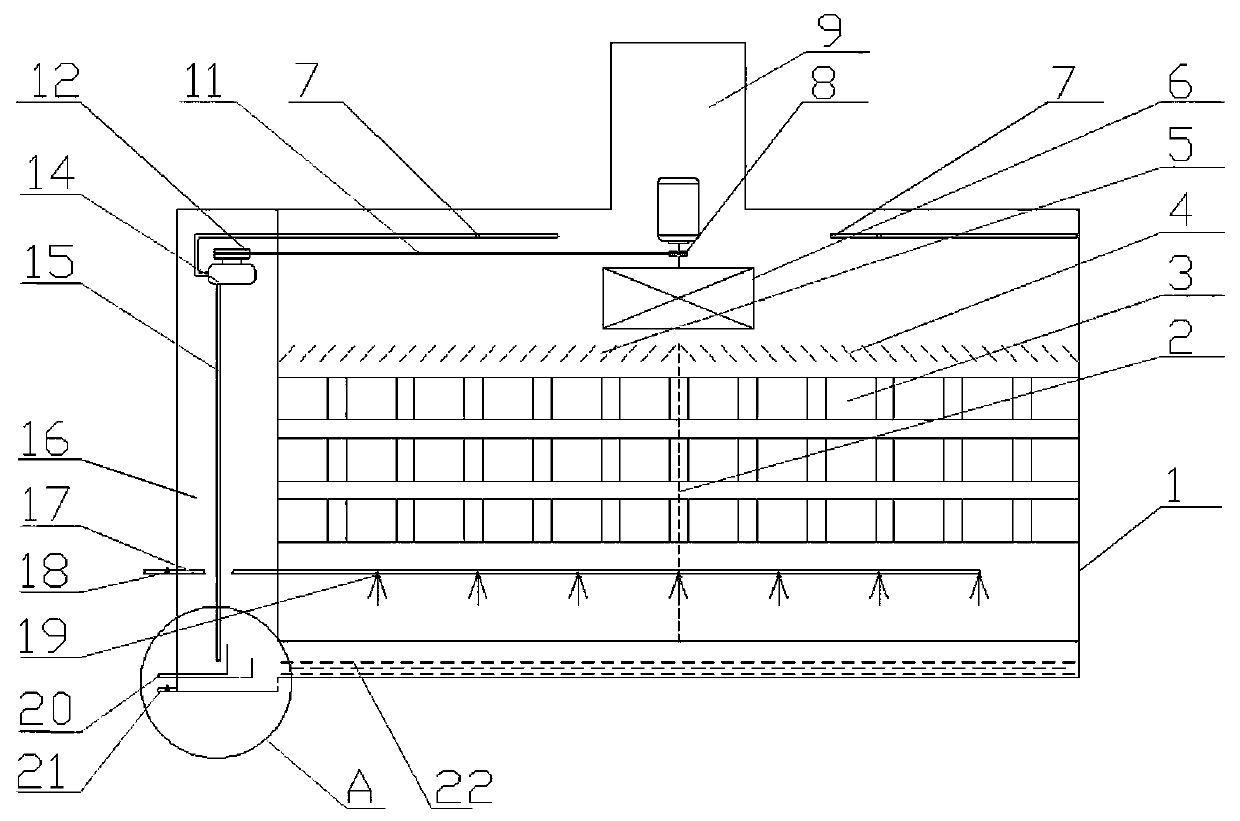

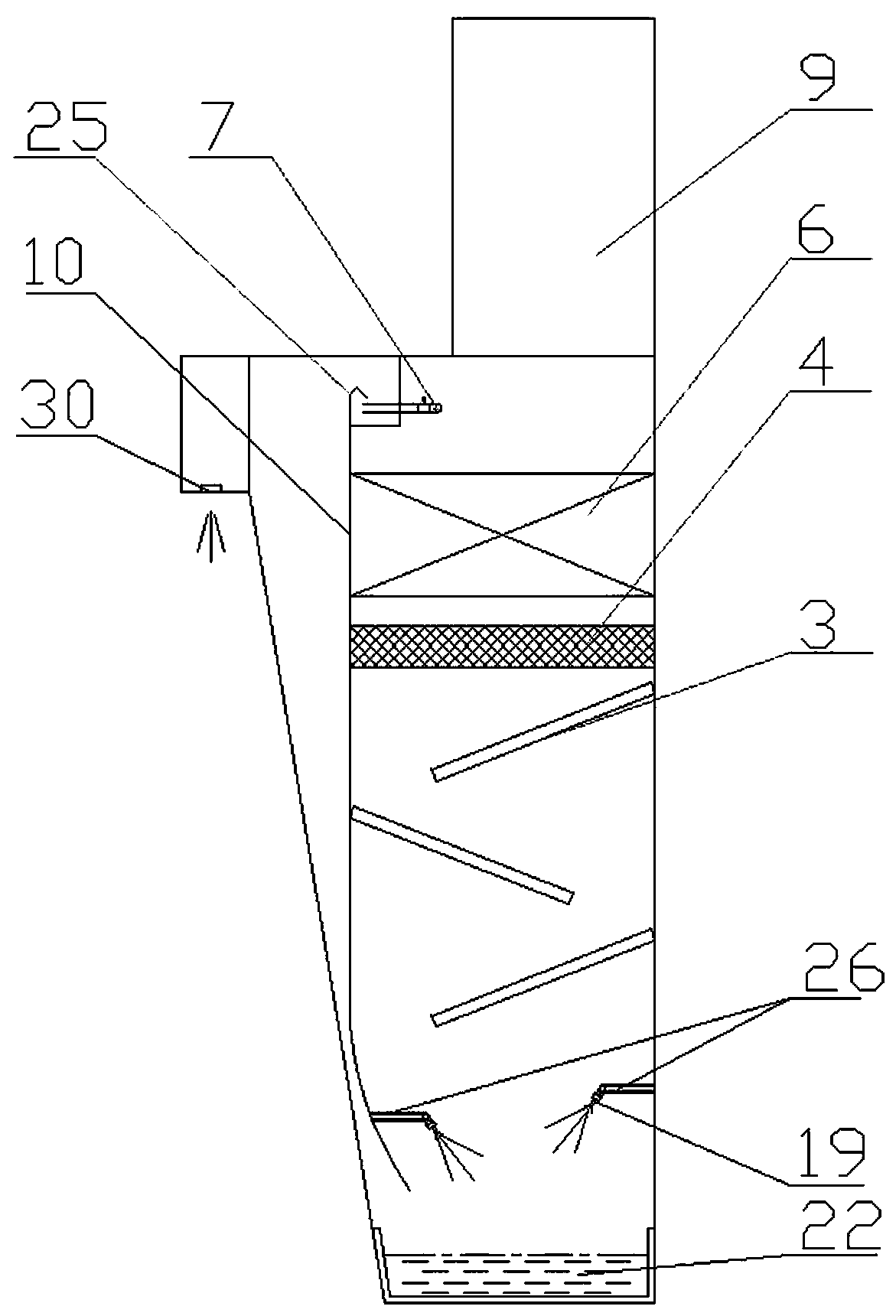

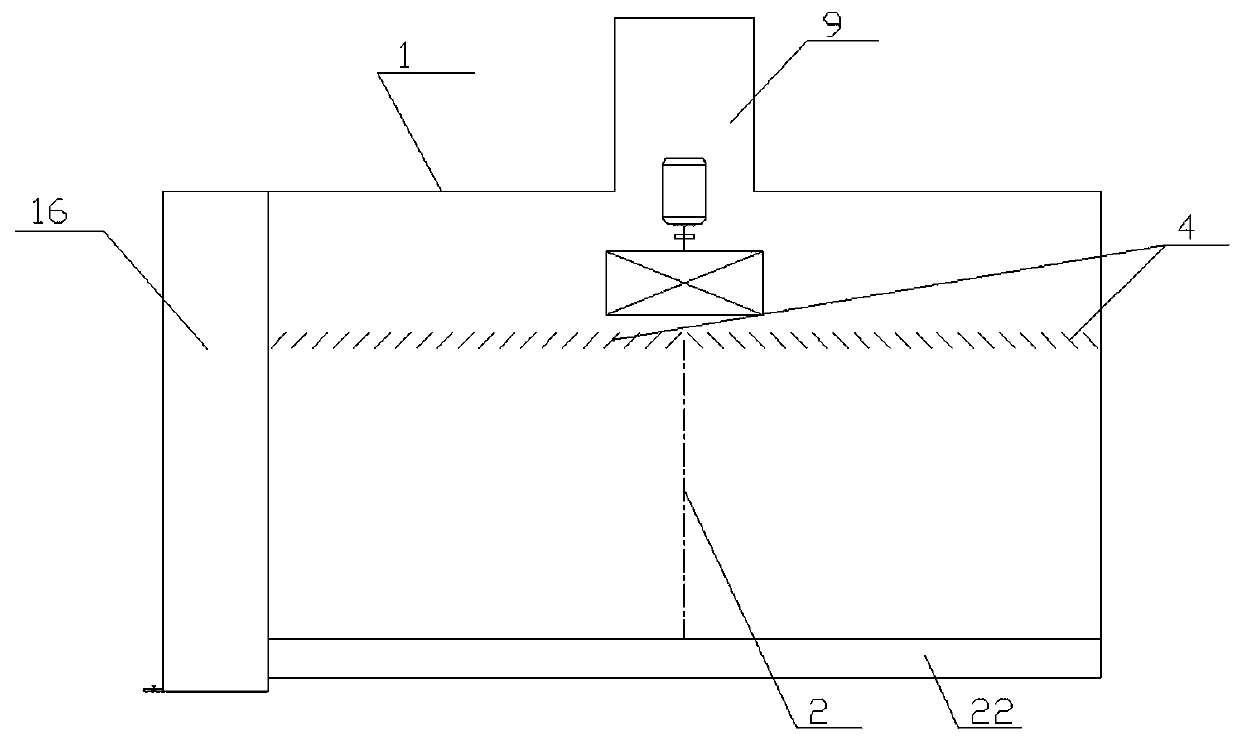

[0032] A water curtain type range hood, comprising a casing 1, a range hood arranged on the casing 1, an adsorption mechanism arranged on the side of the casing and matched with the range hood, arranged on the The circulation mechanism on the housing and below the oil fume mechanism and matched with the adsorption mechanism, the exhaust mechanism arranged on the upper part of the housing and matched with the oil fume mechanism, and the exhaust mechanism arranged on the The control mechanism on the housing is used to control the range fume mechanism, adsorption mechanism, circulation mechanism and exhaust mechanism;

[0033] The fume extraction mechanism includes two fume extraction modules arranged symmetrically on the casing 1 , and a partition plate 2 arranged on the casing 1 for separating the two fume extraction modules.

[0034] The range fume module includes an air inlet 30 arranged on the casing 1 and located at the upper part of the casing, a water curtain plate 10 arr...

Embodiment 2

[0042] It differs from Embodiment 1 in that:

[0043] The exhaust motor in the exhaust fan is provided with a water pump driving wheel 8, and the circulating water pump 14 is provided with a water pump driven wheel 12 for the water pump work, and is arranged between the water pump driving wheel 8 and the water pump driven wheel. Between the connecting belt 11.

[0044] The power source of the circulating water pump adopted in this embodiment is the exhaust motor, and the water pump drive wheel can be arranged on its main shaft, and the water pump driven wheel can be set on the water pump, and the rotation of the circulating water pump can be driven by the rotation of the exhaust motor. Therefore, the aqueous solution in the lower part of the adsorption chamber is sucked into the spray pipe, avoiding setting up a drive on the water pump, and reducing the difficulty of control and circuit.

Embodiment 3

[0046] The difference between it and the second embodiment is that the height of the groove wall of the oil discharge groove 24 near the inner wall of the housing 1 is higher than the height of the side wall far away from the inner wall of the housing 1 .

[0047] The height of the side wall away from the inner wall of the housing used in this embodiment is lower than the height of the side wall near the inner wall of the housing near the oil drain groove, which can not only remove oil stains, but also prevent excessive overflow; traditional The sewage discharge method is either directly discharged, or the cleaning solution is replaced regularly, and there is no need to set up an oil discharge tank; however, the above-mentioned solution will either reduce the adsorption effect after long-term use, or consume a large amount of cleaning agent. However, the above-mentioned method is implemented It is very simple, it saves the cost of structure and materials, and can be used to mak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com