A method for monitoring micro-leakage of a gas meter

A gas meter and tiny technology, which is applied in the direction of instruments, measuring devices, testing/calibrating devices, etc., can solve the problems of insensitivity and inaccuracy in micro leak detection, and achieve the effect of reduced maintenance content, low power consumption and good detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

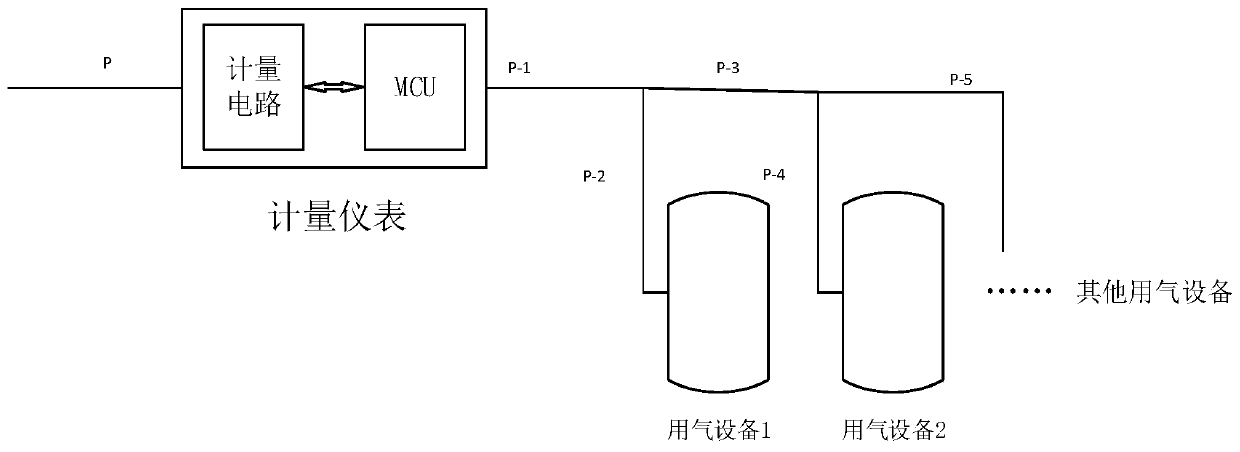

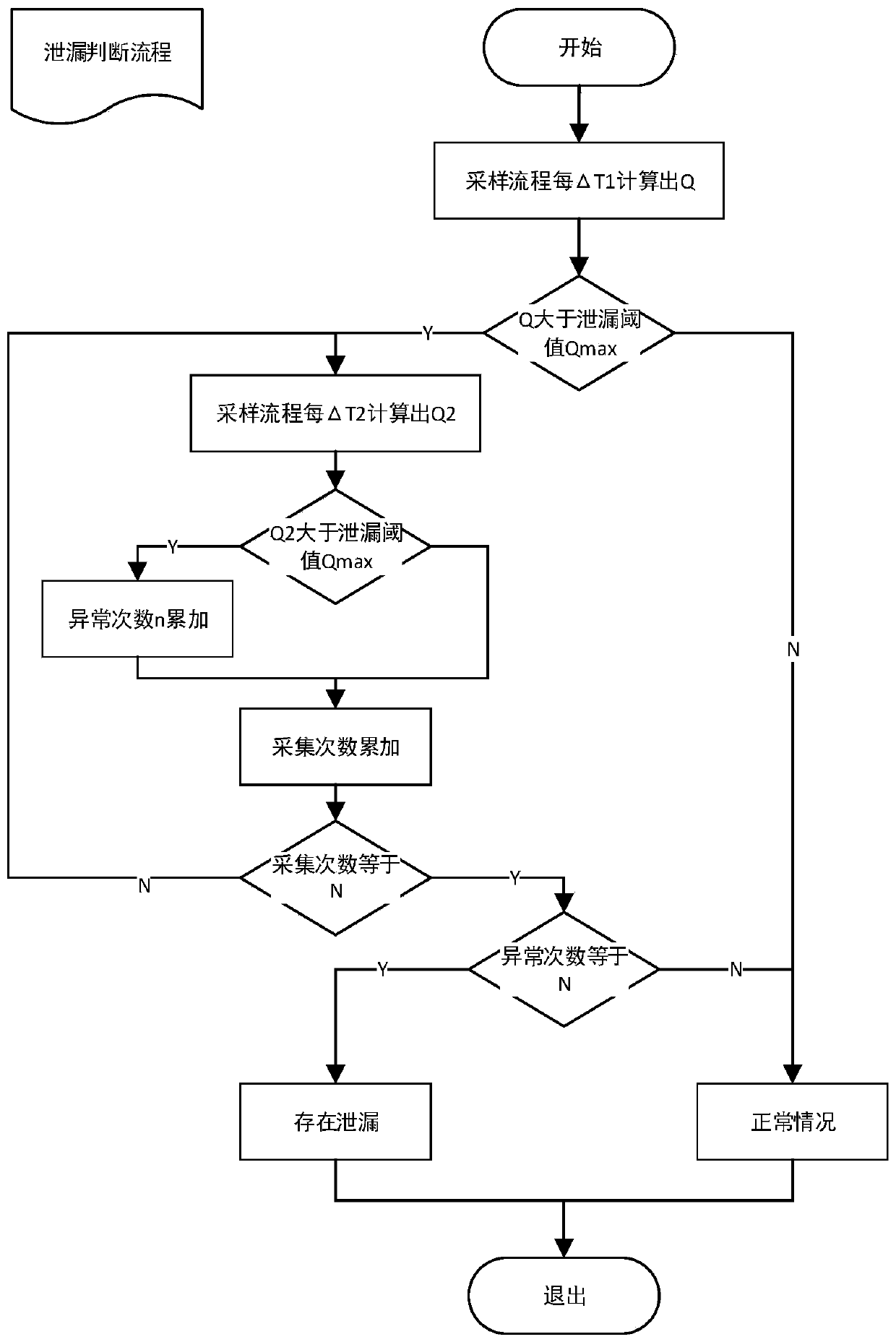

[0031] This embodiment adopts a short-time real-time detection method, and compares the sampling statistical data with a preset threshold to monitor whether there is a tiny leak.

[0032] A method for monitoring tiny leaks with a gas meter, comprising the following steps:

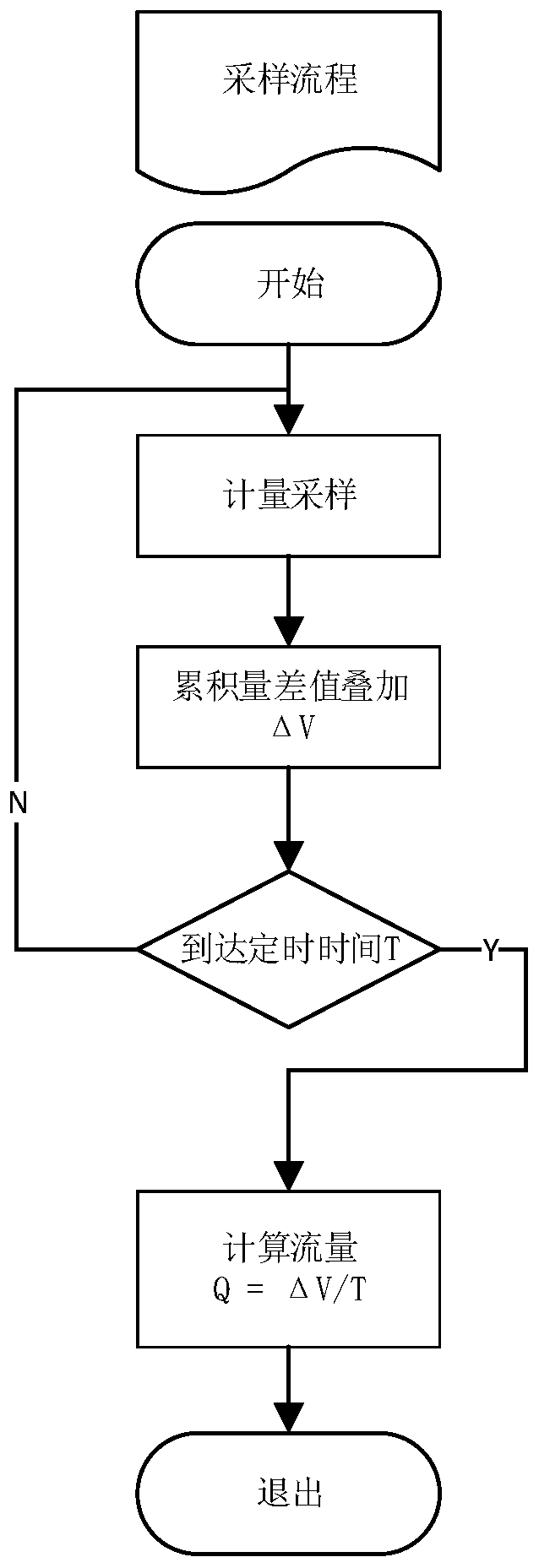

[0033] Step 1: The metering circuit collects gas consumption statistics within the time period △t1, and the processor converts the flow value Q1 within the time period △t1 through the formula: flow = cumulative amount within the time period △t1 / △t1, and completes a flow information records, the process is as follows figure 2 shown.

[0034] Step 2: Comparing the calculated flow value Q1 with the leakage threshold Qmax, and when the flow value Q1 is greater than the leakage threshold Qmax, go to step 3.

[0035] Step 3: Perform acceleration detection, the metering circuit continuously collects the gas consumption in the time period △t2 for N times, where △t2 is less than △t1, the processor calculates the ...

Embodiment 2

[0043] Embodiment two, refer to Figure 4 As shown, this embodiment adopts the variance value and average price comparison method, and uses the gas meter to monitor the flow in real time to improve safety and detection efficiency.

[0044] A method for monitoring tiny leaks with a gas meter, comprising the following steps:

[0045] Step S1, the metering circuit collects the gas consumption at the set time every day, and the processor calculates the flow value samples {Q1,...,Qn} within a day according to the formula: Q=△V / △t, where △V means Set the gas volume for the time, △t means the length of the set time, n means the nth sample, and calculate the variance value S and the average value M of the n samples;

[0046] Step S2, keep the variance value and average value calculated every day to obtain a set of data {(S1,M1),(S2,M2),...,(Sx,Mx)}, where x represents the xth day ;

[0047] Step S3, compare the variance values Sa and Sb of any two days, where a and b represent sp...

Embodiment 3

[0053] Embodiment 3, this embodiment combines Embodiment 1 and Embodiment 2, that is, the two detection methods in Embodiment 1 and Embodiment 2 are carried out at the same time, as long as any detection method detects a leak, the valve is closed and processed. Sound the alarm. Since the two detection methods are integrated, the advantages of the two detection methods can be combined, and the disadvantages of the two detection methods can be avoided, so that the detection effect is better and the safety is higher.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com