A vacuum circuit breaker and its vacuum interrupter

A vacuum interrupter and vacuum circuit breaker technology, which is applied to high-voltage air circuit breakers, circuits, high-voltage/high-current switches, etc., can solve problems such as circuit breaker reliability degradation, and improve work reliability, reliability, The effect of reducing the mechanical life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

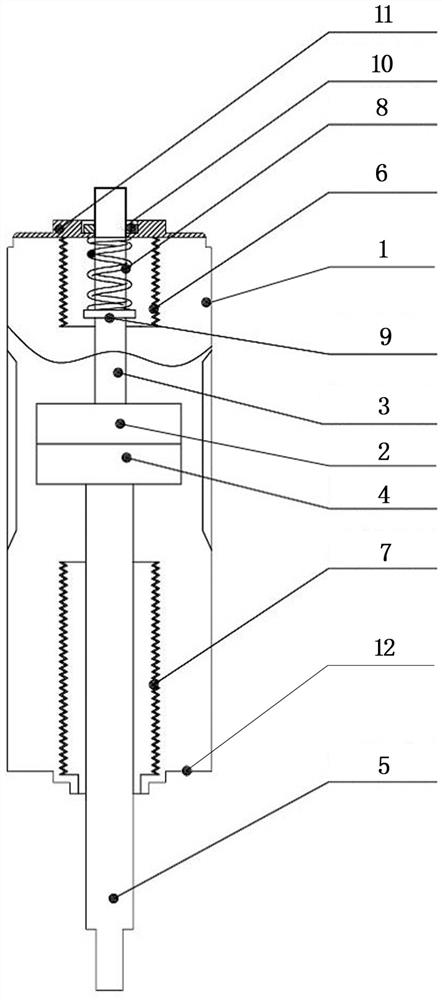

[0025] Such as figure 1 As shown, the vacuum interrupter includes a shell extending in the up and down direction, the shell is a ceramic shell 1, the upper end of the ceramic shell 1 is provided with a static end cover 11 and the lower end is provided with a movable end cover 12, the static end cover 11 and the movable end cover 12 The center is equipped with a static conductive rod 3 and a movable conductive rod 5 corresponding to activities, and the lower end of the static conductive rod 3 and the upper end of the movable conductive rod 5 are correspondingly provided with a static contact 2 and a movable contact 4 . The movable conductive rod 5 is sheathed with a movable end bellows 7 whose upper end is sealed and fixedly connected with the movable conductive rod 5 and whose lower end is sealed and fixedly connected with the movable end cover 12 . A stop ring 9 protrudes from the outer circumference of the static conductive rod 3, and a pressure spring 8 set on the static co...

Embodiment 2

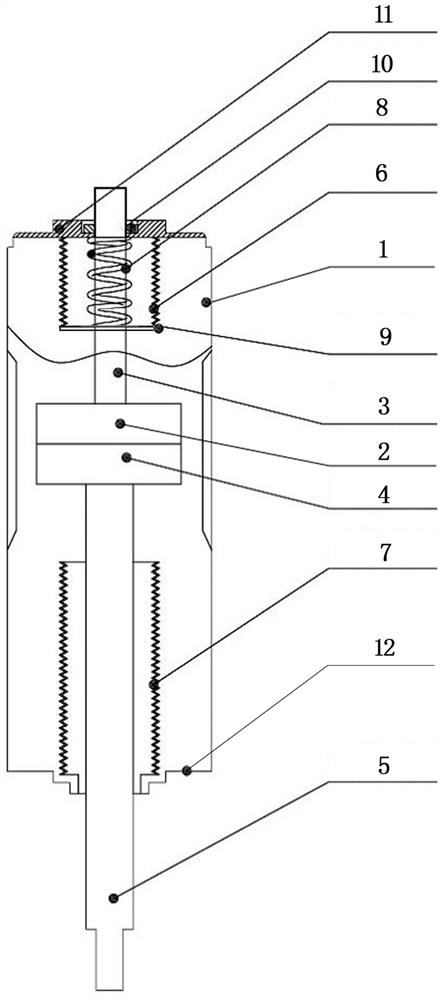

[0031] Such as figure 2 As shown, the main difference between the vacuum interrupter provided in this embodiment and the first embodiment is that the lower end of the bellows 6 at the static end is sealed and fixed on the stop ring 9 . Sealing and fixing the bellows 6 at the static end to the stop ring 9 can save the inner space of the vacuum interrupter, so that the vacuum interrupter can be further miniaturized to adapt to the working occasions with limited space.

Embodiment 3

[0033] The main difference between the vacuum interrupter provided in this embodiment and that in Embodiment 1 is that a longitudinal magnetic field contact is used in this embodiment. At present, there are mainly transverse magnetic field contacts and longitudinal magnetic field contacts with spiral arc running surfaces on the market. The longitudinal magnetic field contacts have better arc extinguishing ability, which can improve the arc extinguishing ability of the vacuum interrupter provided by this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com