Cutting device for printing machine

A cutting device and printing press technology, applied in metal processing and other directions, can solve the problems of paper incision curling, affecting mechanical life and cutting accuracy, affecting paper quality, etc., to ensure cleanliness, suitable for promotion and use, and convenient for cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

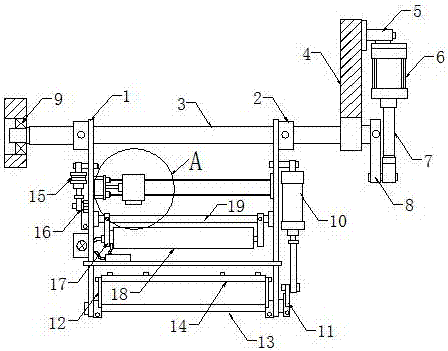

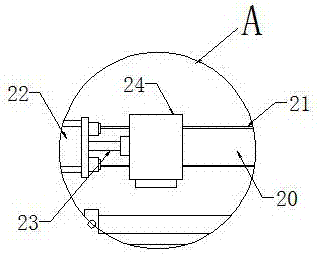

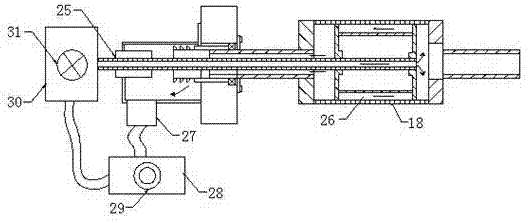

[0021] Such as Figure 1-3 As shown, this specific embodiment adopts the following technical solutions: a cutting device of a printing machine, including a cutting arm 1, a coupling 2, a guide shaft 3, a fixing plate 4, a fixing member 5, a cutting arm cylinder 6, and a piston rod 7 , the first crank 8, the bearing 9, the cutter cylinder 10, the second crank 11, the cutter arm 12, the cutter shaft 13, the cutter 14, the roller cylinder 15, the third crank 16, the roller arm 17, the roller 18 and the pressure roller shaft 19, a guide shaft 3 is installed between the cutting arm 1, and one end of the guide shaft 3 is connected with the drive shaft on the fixed plate 4 through the coupling 2, and the fixed plate 4 is rotationally connected with the drive shaft through the bearing 9, And the transmission shaft is connected with the piston rod 7 of the output end of the cutting arm cylinder 6 through the first crank 8, the cutting arm cylinder 6 is fixed on the side end of the fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com