Fan type metal corrugated pipe plane bending device

A metal bellows, plane bending technology, applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of pipe fracture, pipe sample stress concentration, metal bellows unfixed temporary, etc., to achieve force The effect of uniformity, strong durability, high application value and promotion prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

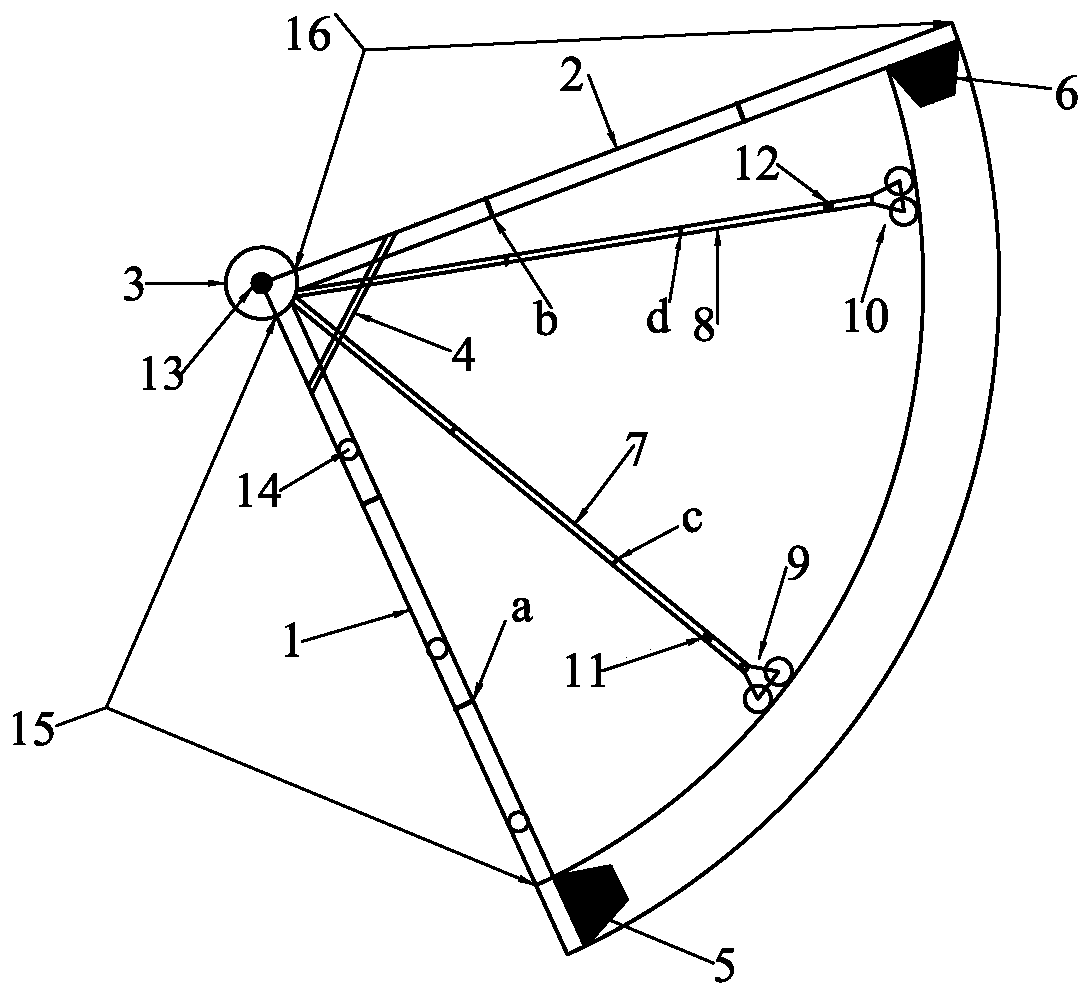

[0046] The present invention is briefly explained and introduced below:

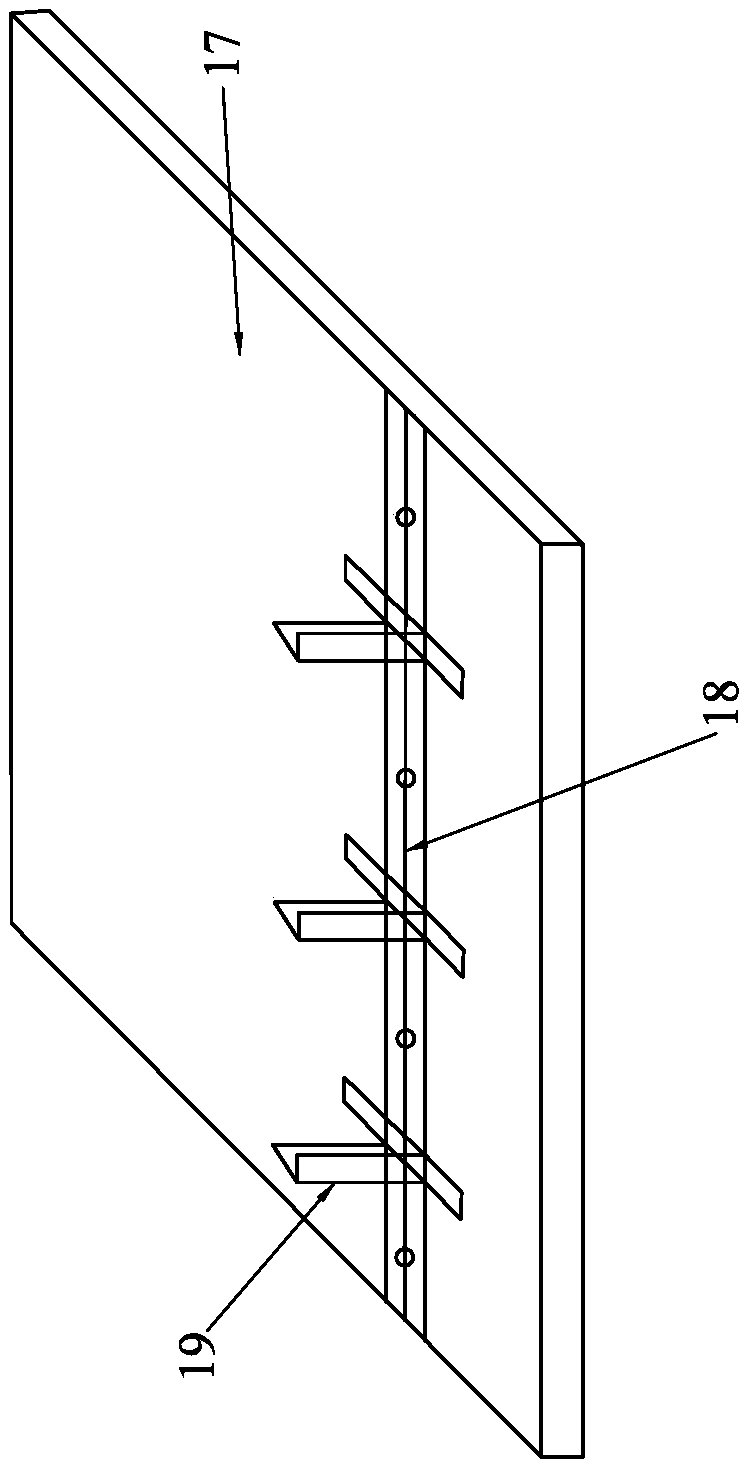

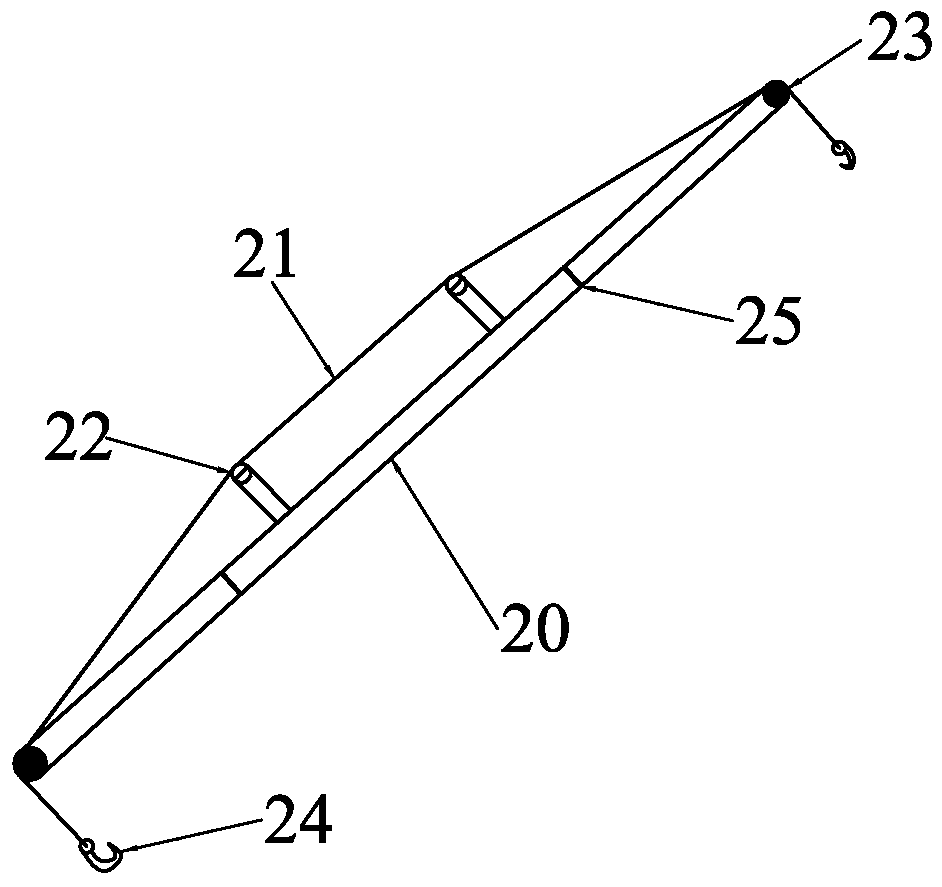

[0047] The detection device is composed of a bending system, a fixing system and a shaping system; among them, the bending system is the main working system and structural body of the device, and its components include: main arm, auxiliary arm, main arm fixing clip, auxiliary arm fixing Clamp, main pendulum, auxiliary pendulum, main pendulum sweeping wheel, auxiliary pendulum sweeping wheel, main pendulum push rod, auxiliary pendulum push rod, connecting wheel main fixing pin hole, main arm auxiliary fixing pin hole; fixing system It is mainly a metal plate with sliding rails and fixed pins; while the shaping system is a telescopic rod with pulleys and hanging hooks, and is equipped with several fixing hoops for auxiliary connection with pipe samples.

[0048] Further, the support system is composed of a main arm, an auxiliary arm, a main arm fixing clip, an auxiliary arm fixing clip, a main pendulum, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com