Novel lightweight automobile hub

A lightweight technology for automobile wheels, applied in the direction of wheels, highly elastic wheels, rims, etc., can solve the problems of small heat dissipation surface of rims, violent body bumps, poor driving comfort, etc., to slow down radial impact, ensure radial support, The effect of slowing down the circumferential impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

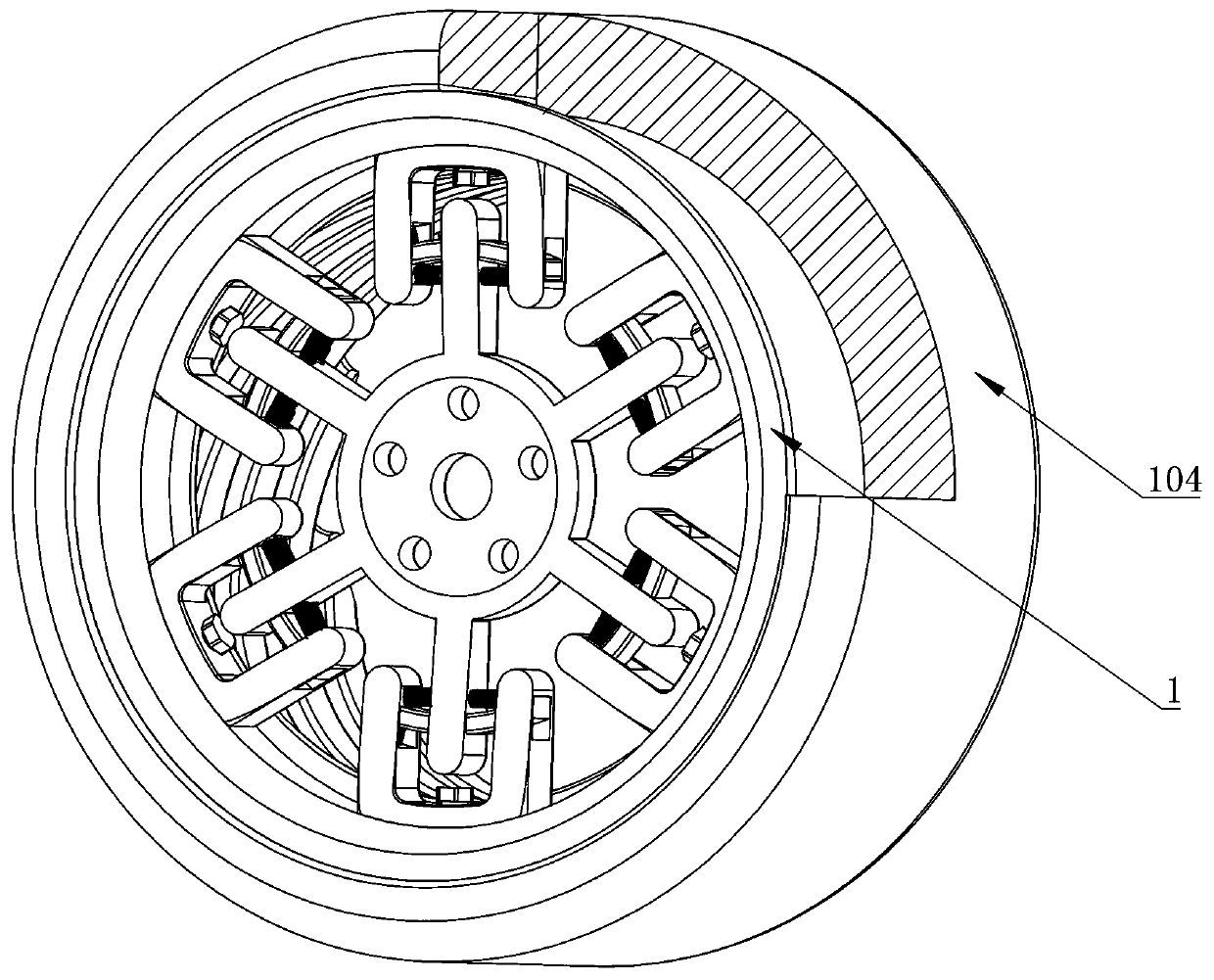

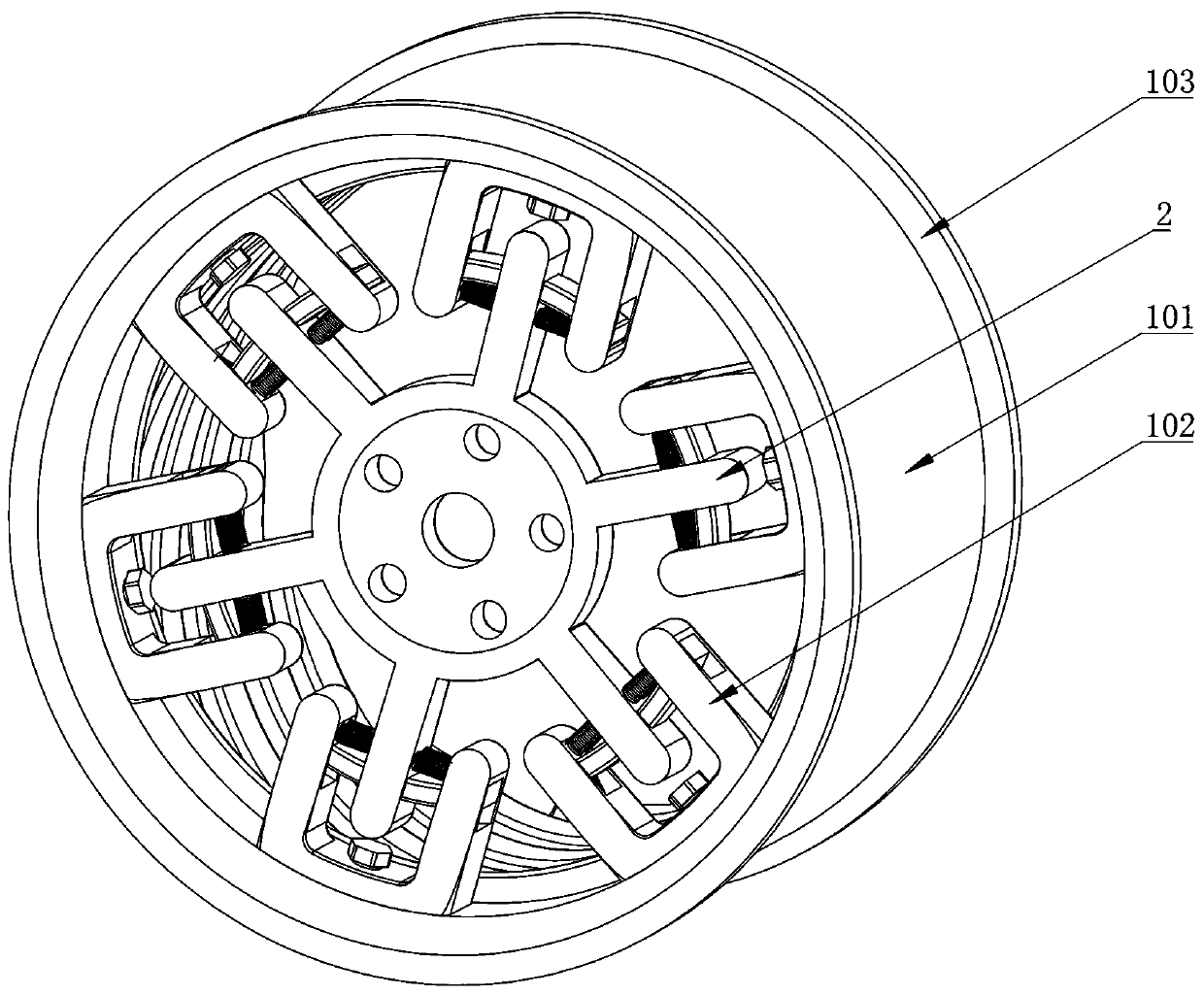

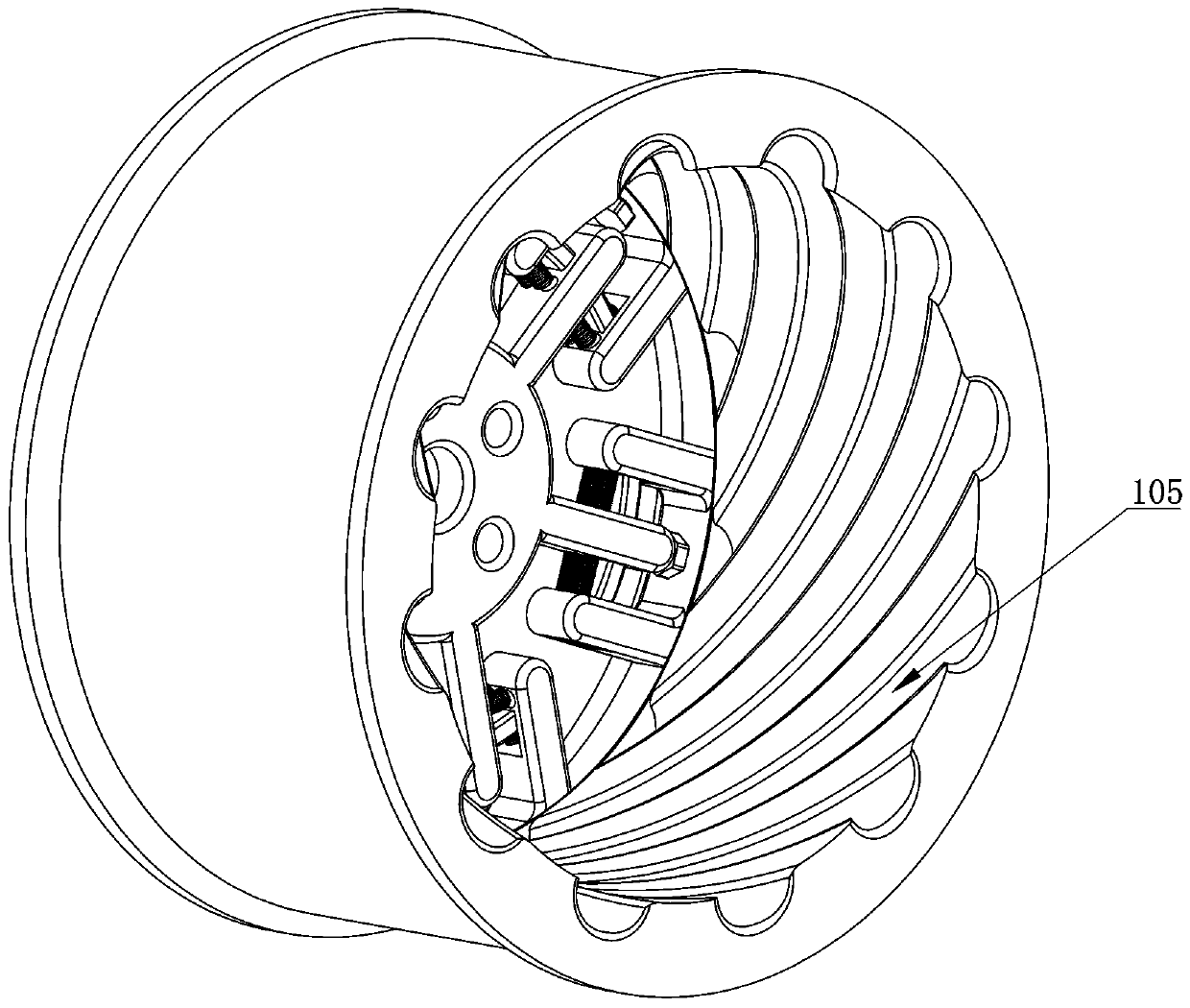

[0016] Specific implementation method: combined Figure 1-5 As shown, it includes a wheel hub 1; the wheel hub 1 includes a rim 101 and a spoke 102; the rim 101 is symmetrically provided with bead seats 103 on both sides in the width direction; the upper part of the rim 101 is provided with a tire 104; respectively clamped with the bead seat 103; the inner circumference of the rim 101 is uniformly provided with multiple sets of spiral grooves 105; one side of the rim 101 is provided with multiple sets of the spokes 102; the spokes 102 and the The rims 101 are connected by bolts; the center position outside the hub 1 is provided with a drive frame 2; the spokes 102 are U-shaped as a whole; First springs 107 are symmetrically arranged on both sides of the inner width direction of the shaped through groove 106; the upper end of the first spring 107 is engaged with the spokes 102; the outer circumference of the transmission frame 2 is evenly provided with multiple groups of transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com