Material melting device

A chemical materializer and chemical barrel technology, applied in the directions of loading/unloading, conveyors, flanged bottle caps, etc., can solve the problems of poor sealing performance, troublesome processing, low production efficiency, etc., and achieve a convenient and fast process. , Improve production efficiency and enhance the effect of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

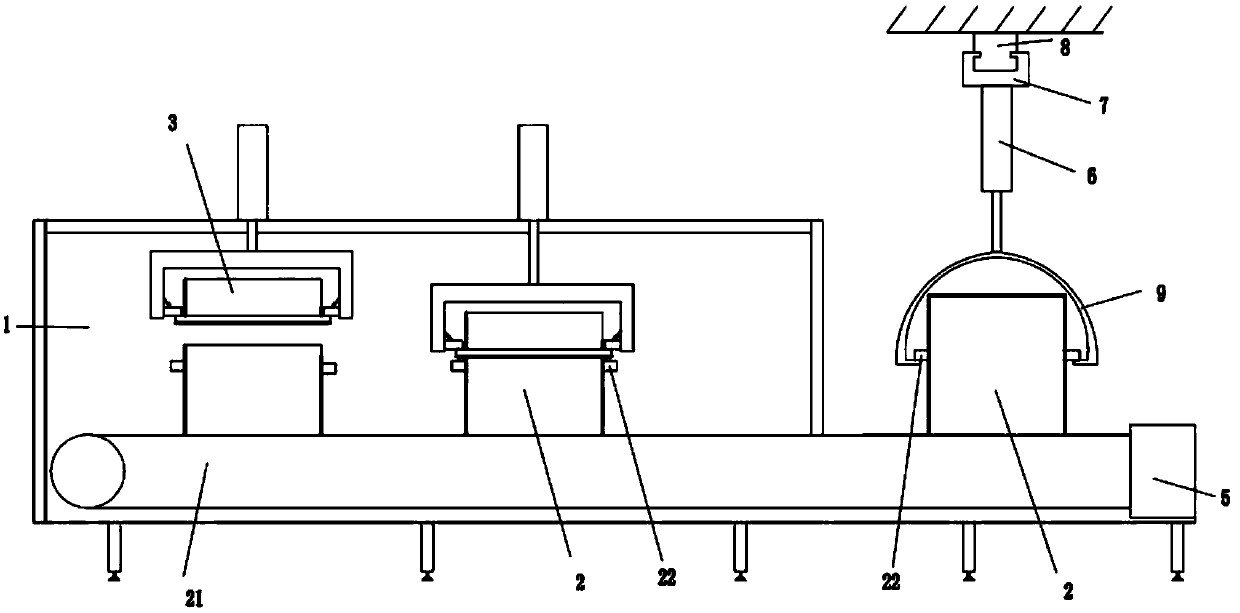

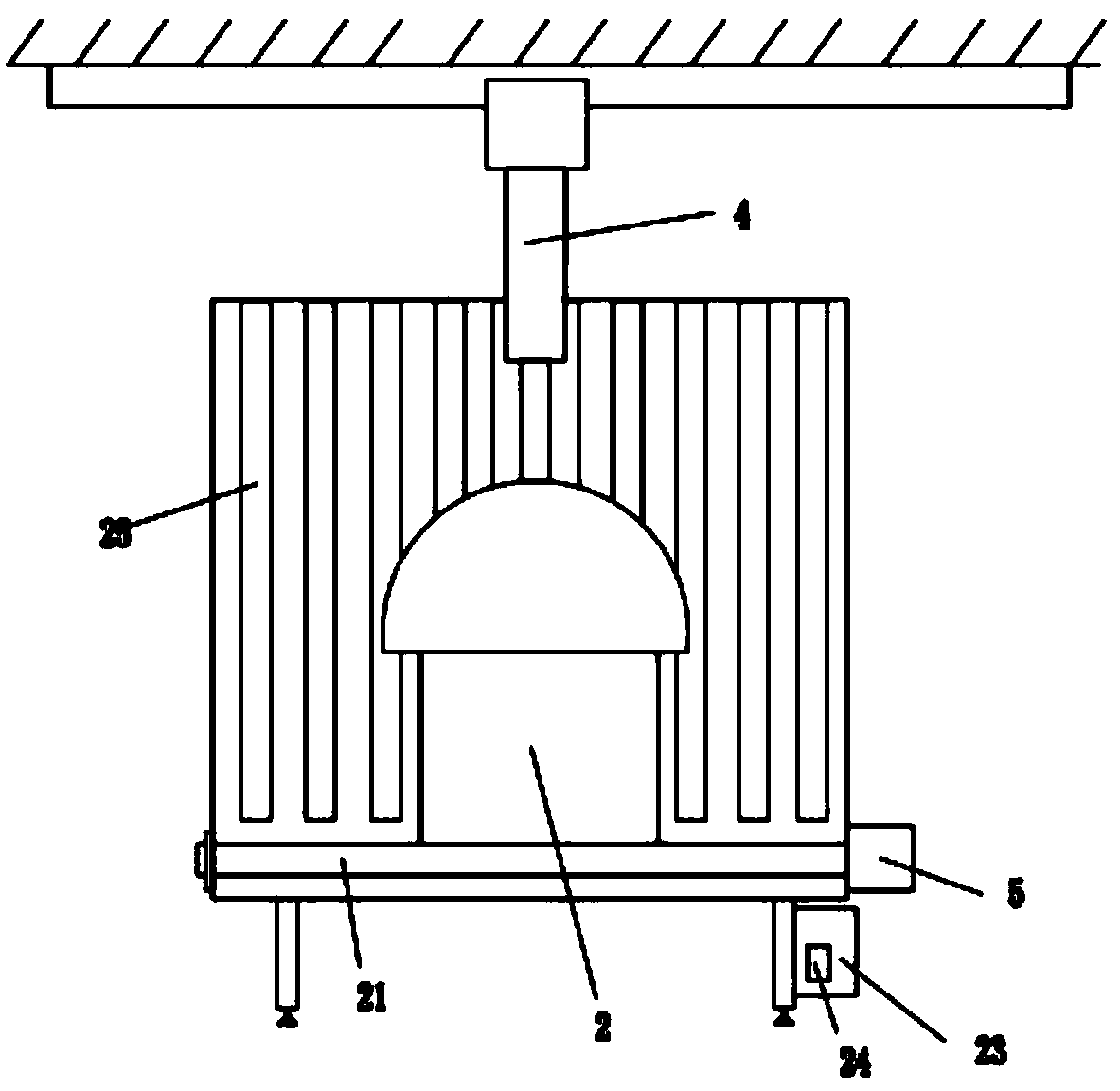

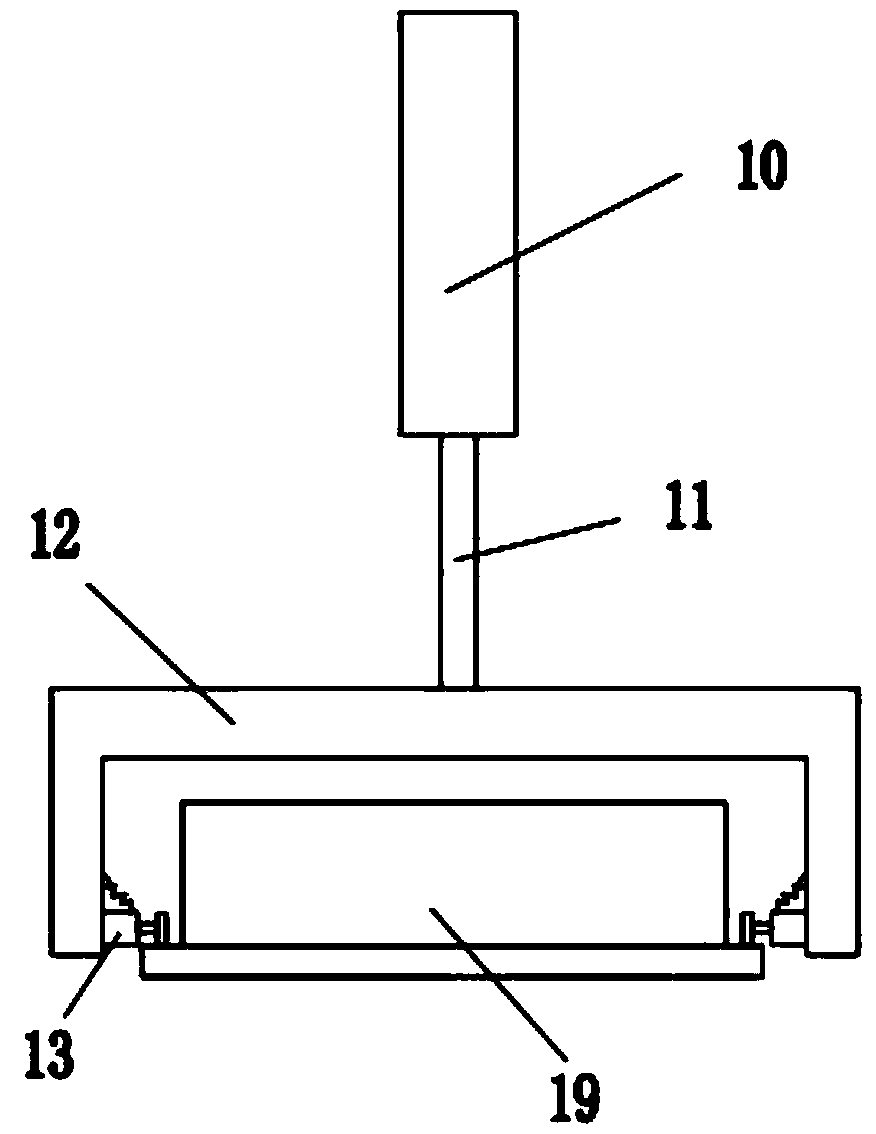

[0017] A chemical feeder, comprising a chemical feed bin 1, a conveyor belt 26 is arranged inside the chemical feed bin 1, a drive motor 5 is provided outside the chemical feed bin 1 to drive the conveyor belt 26 to rotate, and the conveyor belt 26 is provided with There is a chemical material tank 2, and the chemical material tank 1 is provided with a capping device 3 corresponding to the chemical material tank 2, and the capping device 3 includes hangers 12 and cylinders 10 respectively located inside and outside the chemical material tank 1, A lifting rod 11 is provided between the hanger 12 and the cylinder 10, buffer devices 13 are provided on both sides of the hanger 12, and a cover 19 is arranged between the buffer devices 13 on both sides, and the cover 19 passes through the cylinder. 10 Control the lifting rod 11 to drive the hanger 12 to move up and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com