Washing machine and washing method thereof

A washing machine and washing block technology, applied in the field of washing machines, can solve the problems of residual washing powder, loud noise, and increased damage of clothes, and achieve the effect of increasing the washing effect, increasing the mode, and washing the clothes clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

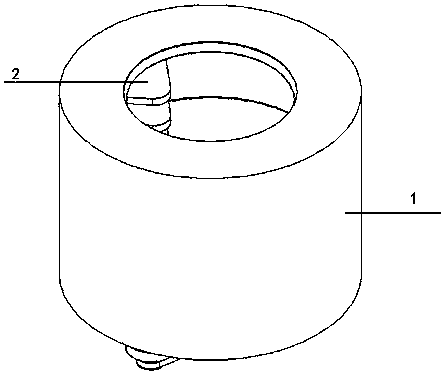

[0051] Such as figure 1As shown, the scrubbing washing machine of the present invention includes an outer cylinder 1 and an inner cylinder, and the inner wall of the inner cylinder is provided with a washing block 2 . The scrubbing washing machine can be a vertical washing machine with an upward opening, or a drum washing machine with an opening on the side.

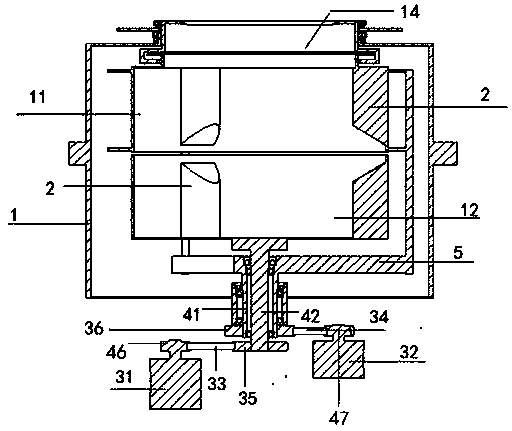

[0052] Such as figure 2 As shown, the scrubbing washing machine of the present invention includes an outer cylinder 1 and an inner cylinder, the inner cylinder is divided into a first inner cylinder 12 and a second inner cylinder 11, and the first inner cylinder 12 and the second inner cylinder 11 are stacked to form an inner cylinder and two Both of them can be rotated, and one or more washing blocks 2 are arranged on the arc surface of the inner wall of the first inner cylinder 12 and the second inner cylinder 11. The washing block 2 is a raised structure, which can be a block structure or a Sheet structure.

[005...

Embodiment 2

[0060] Such as Image 6 As shown, the scrubbing washing machine of the second embodiment of the present invention can be provided with a vibrating motor 61 on the outer cylinder 1 or the inner cylinder in order to increase the washing effect, and the vibrating motor 61 can increase the washing block 2 and who. The outer cylinder 1 is connected with an installation platform 6 on which a vibration motor 61 is installed.

Embodiment 3

[0062] Such as Figure 7 As shown, the scrubbing washing machine of the third embodiment of the present invention differs from the first embodiment in that: a plectrum 15 is added at the bottom of the inner cylinder, and the plectrum 15 can play the role of stirring the water flow.

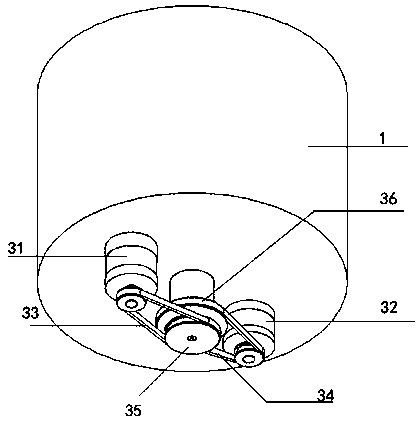

[0063] Such as Figure 8 As shown, after increasing the plectrum 15, it is also necessary to increase the power unit to drive it. Therefore, a third motor 37 , a third pulley 38 , a sixth pulley, a third belt 39 and a third rotating shaft 43 are added at the bottom of the tub 1 . The third motor 37 drives the sixth pulley to rotate, the sixth pulley is connected with the third pulley 38 by the third belt 39, the third pulley 38 is connected with one end of the third rotating shaft 43, and the other end of the third rotating shaft 42 is connected with the paddle 15 is connected, and the paddle 15 is positioned at the bottom of the inner cylinder. When the third motor 37 works, it can make the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com