Top cover type cleaning device

A top-cover type, washing device technology, applied to washing devices, other washing machines, washing machines with containers, etc., can solve problems such as bulky land occupation, time-consuming and power consumption, body installation and safety issues cannot be guaranteed, and achieve Reduce the loss along the process, shorten the spraying distance, and save a lot of time-consuming and power-consuming effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

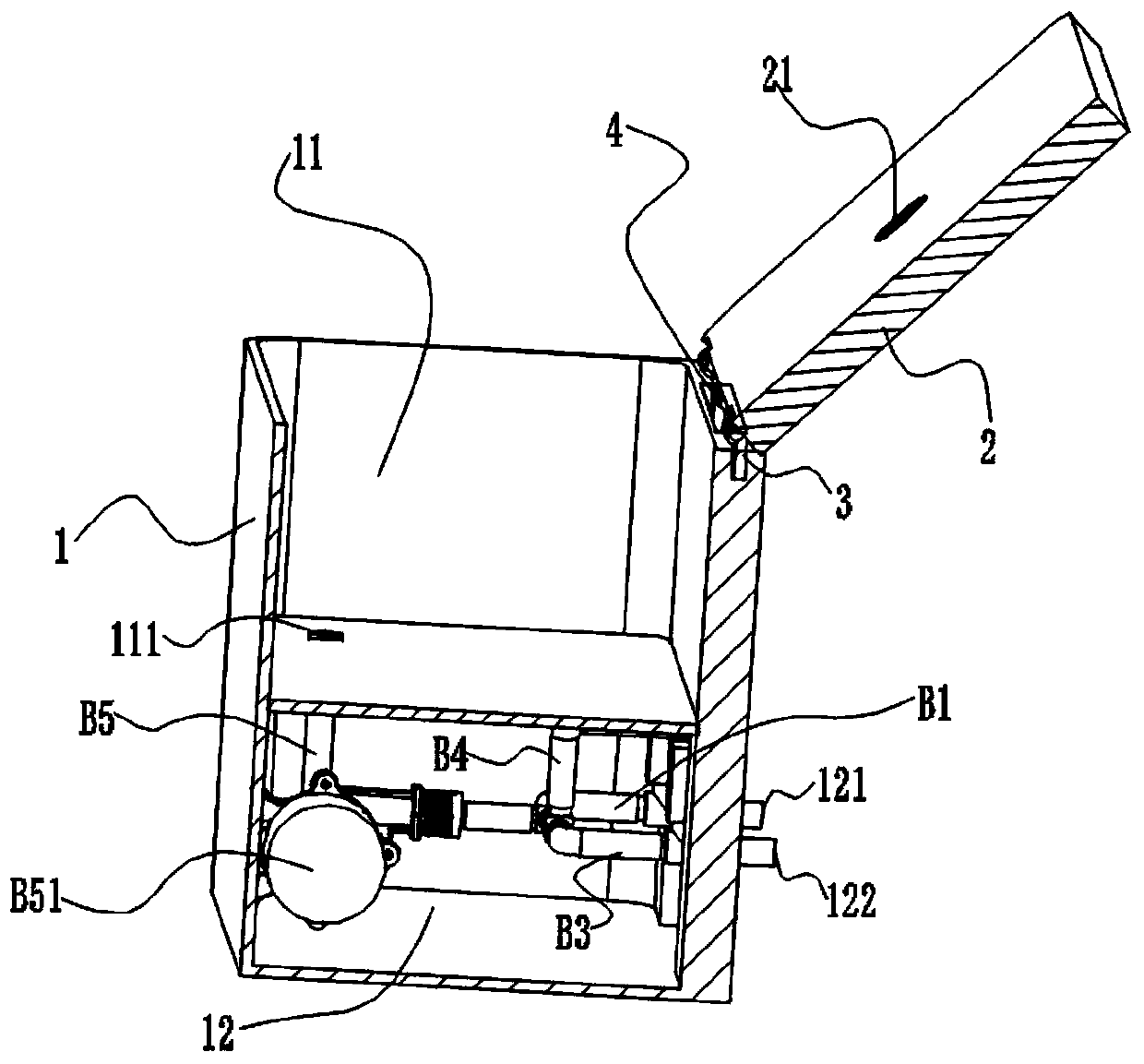

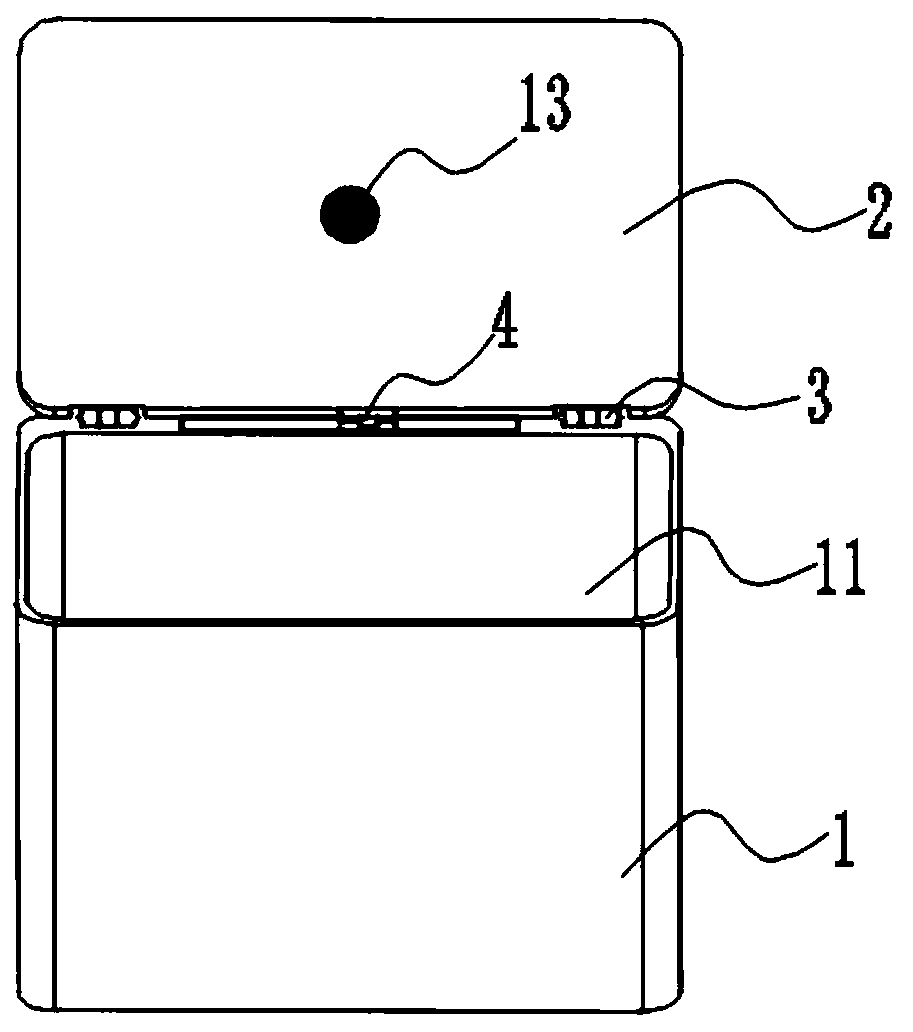

[0044] Such as Figure 1-7 As shown, the present embodiment provides a top cover type cleaning device, which includes:

[0045] The bucket body 1 has a washing cavity 11 formed therein for containing laundry to be washed.

[0046] Preferably, the lower part of the bucket body 1 is provided with a pipeline chamber 12, which is used to realize the arrangement of the water pipeline and the circulation pump B51. The washing chamber 11 and the pipeline chamber 12 are separated by a partition. Further preferably, a washing drain 111 is provided on the partition , used to discharge the washing water in the washing chamber 11 after washing.

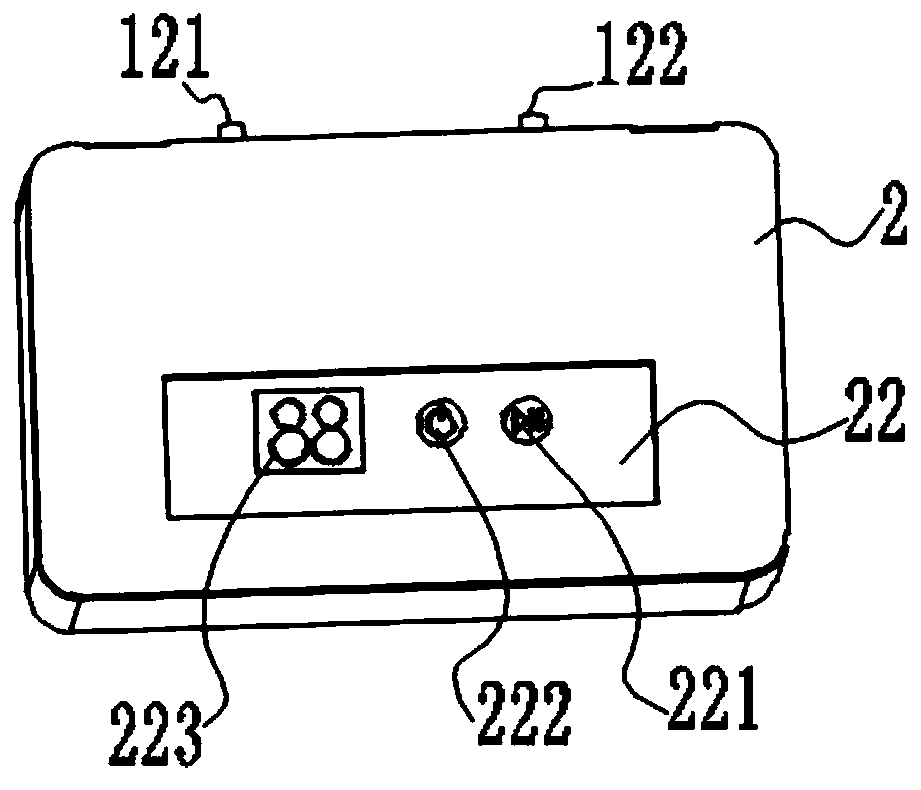

[0047] The top cover 2, the top cover 2 is hinged above the washing chamber 11 for closing the washing chamber 11, the top cover 2 is formed with a spray structure 21 on the side facing the washing chamber 11, so that the washing device can flow from the top cover 2 into the washing chamber 11 Implement spraying and integrate the top cover 2 an...

Embodiment 2

[0084] This embodiment provides another top-cover type cleaning device. The difference from Embodiment 1 is that no heating device is provided in the memory alloy hinge 3 in this embodiment, but a motor is used as the driving source, and the motor is combined with the memory alloy. Page 3 is driven and connected, the power output end of the motor is connected with the second hinge 31, and the rotation of the motor drives the second hinge 31 to turn over, thereby realizing the opening or closing of the top cover 2, and the rest are the same as in Embodiment 1, here No longer.

[0085]To sum up, the roof-type cleaning device provided by the present invention integrates the spray structure 21 with the external roof 2 to form an integrated roof 2, strips the water channel at the water inlet end of the washing chamber 11 from the bottom, and connects with the roof 2 Together, the internal structure of the bottom water system and electrical system is greatly optimized, and the tradi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com