Rapid transfer method and equipment of super-large bridge girder erection machine for assembled steel-concrete composite bridge

A transfer method and technology of a bridge erecting machine, which are applied in the erection/assembly of bridges, bridge construction, bridges, etc., can solve the problems of multiple time and consumption, shorten the construction period, save the construction cost, and save the time of repeated disassembly and assembly. and cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with drawings and embodiments.

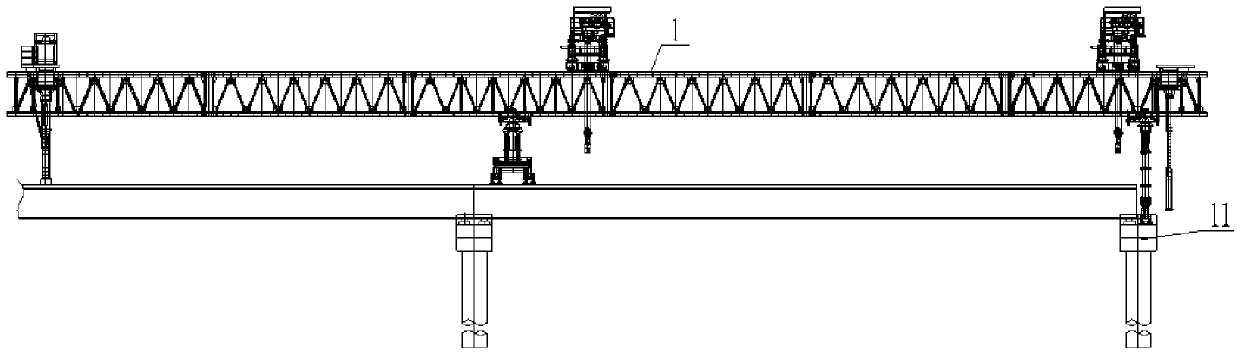

[0055] The present invention provides a whole rapid transfer method of a super-large bridge erecting machine for an assembled steel-concrete composite bridge, referring to Figure 1 to Figure 16 , including the following steps:

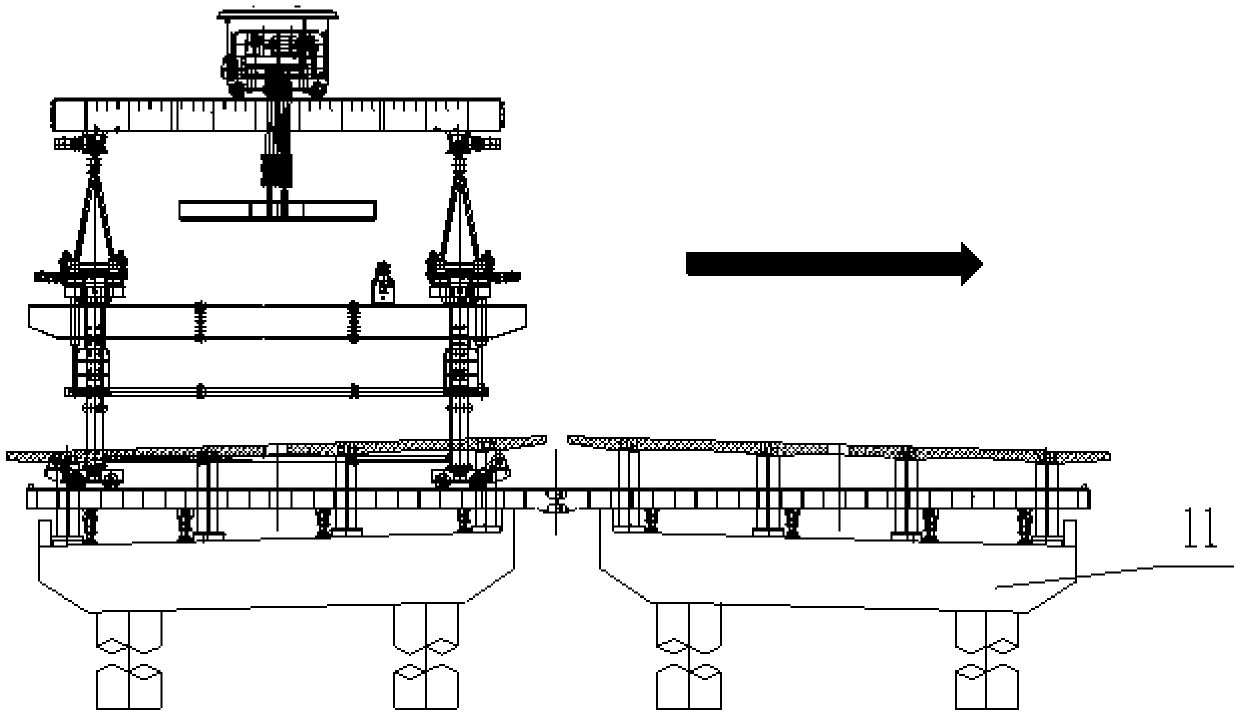

[0056] (1) The bridge erecting machine 1 is ready to be transported after the girder erection of the first bridge width is completed, and the bridge erection machine 1 is driven to the middle position of the pier, and the bridge erection machine 1 is moved laterally to the top of the second bridge width;

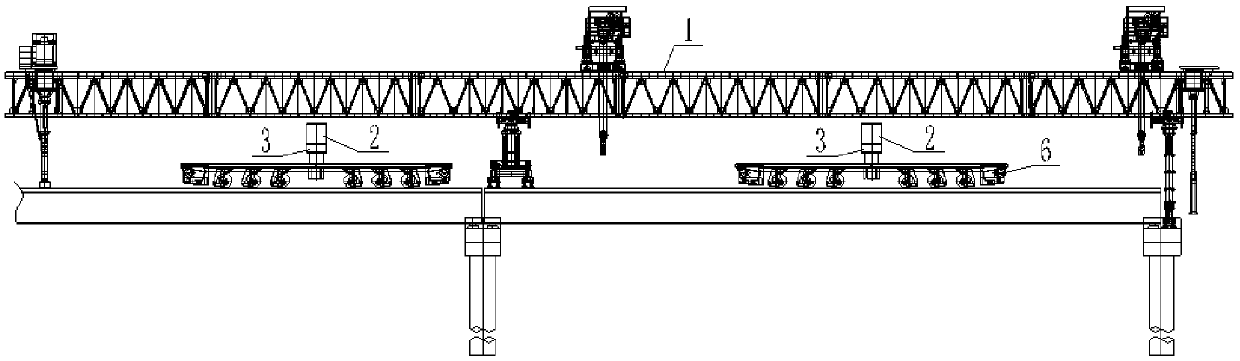

[0057] (2) Install the special tooling beam 2 for transfer on the beam transport vehicle 6 of the first bridge width through the connection base 3, set the anti-overturning outriggers 4 at both ends of the special tooling beam 2 for transfer, and set the auxiliary scroll wheel;

[0058] (3) Drive the beam transporter 6 to the position betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com