Pulley body of door and window pulley and door and window pulley

A technology of pulleys and wheel bodies, which is applied in door/window accessories, wing leaf suspension devices, wing leaf parts, etc. It can solve the problems of non-recoverable, plastic pulley deformation, indentation, etc., and achieve good user experience and no blockage Feeling, smooth sliding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

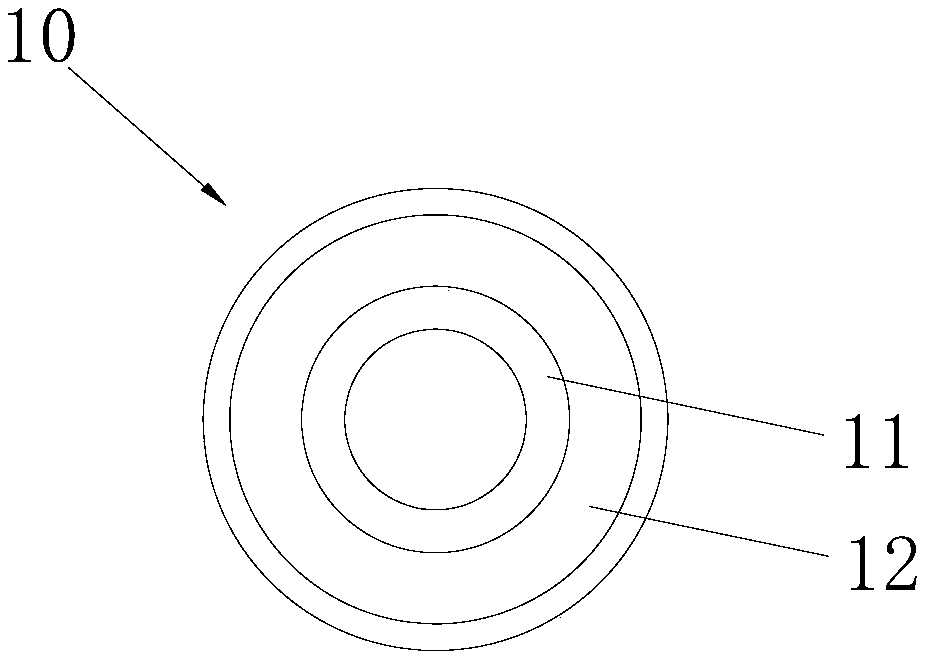

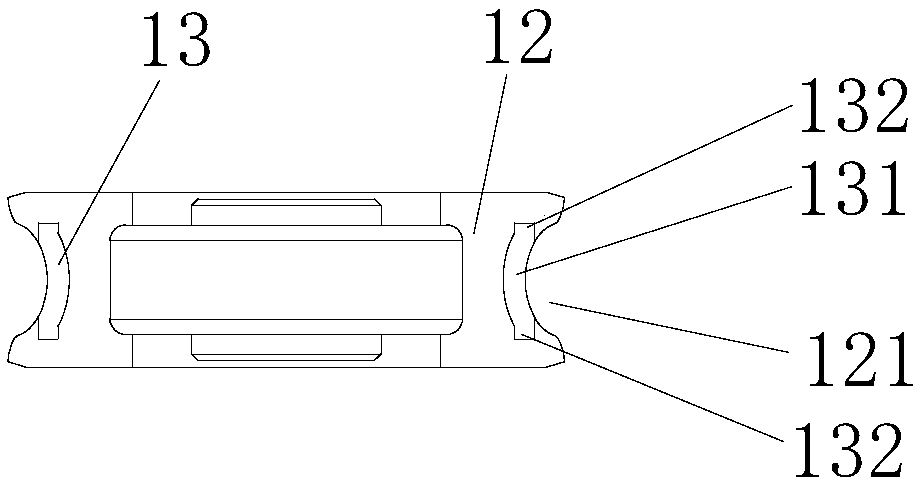

[0029] like Figure 1 to Figure 4 As shown, the wheel body 10 of a door and window pulley provided by the embodiment of the present invention includes a bearing 11, a buffer ring 12 and a rigid ring 13 that can be in contact with the guide rail. The inner side of the buffer ring 12 is connected to the outer side of the bearing 11. , the rigid ring 13 is separated from the outside of the bearing 11 by the buffer ring 12, that is, the rigid ring 13 is not in direct contact with the bearing 11, the rigid ring 13 is sleeved on the buffer ring 12, and / Or, part of the rigid ring 13 is embedded inside the buffer ring 12, that is, the rigid ring 13 can be entirely sleeved outside the buffer ring 12, and the rigid ring 13 can also be partially exposed, and the exposed part of the rigid ring 13 can be used to contact with the guide rail , part of the rigid ring 13 can be embedded in the buffer ring 12, which is more conducive to the buffer ring 12 to disperse the load of the rigid ring...

Embodiment 2

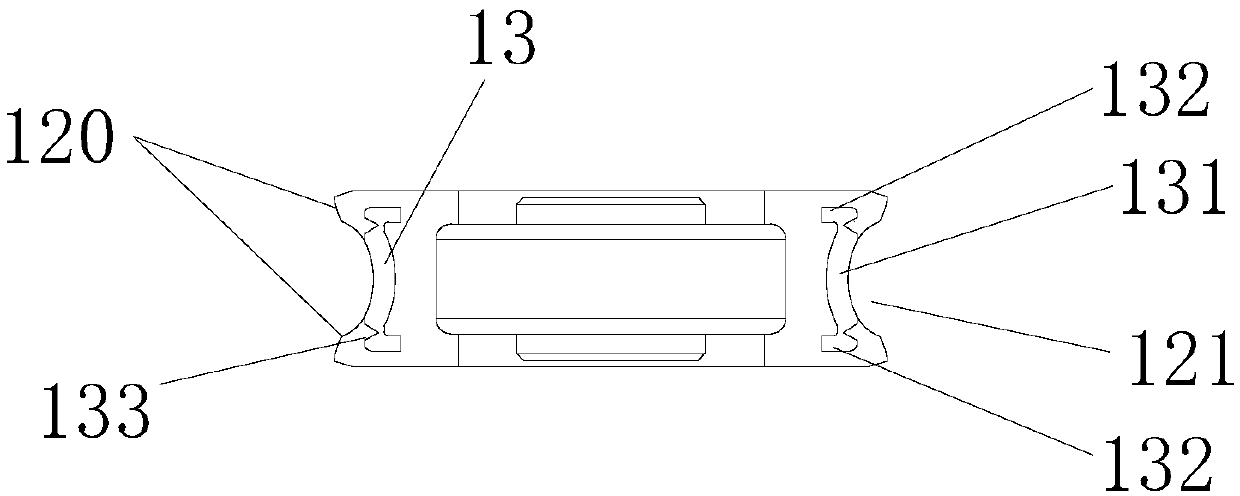

[0049] like Figure 5 to Figure 8 As shown, the wheel body 10 of a door and window pulley provided by the embodiment of the present invention includes a bearing 11, a rigid ring 13, and a buffer ring 12 arranged between the bearing 11 and the rigid ring 13. The buffer ring 12 The inner side of the buffer ring 12 is connected to the outer side of the bearing 11 , and the outer side of the buffer ring 12 is connected to the inner side of the rigid ring 13 . By adopting the rigid ring 13 and setting the buffer ring 12 between the rigid ring 13 and the bearing 11, the rigid ring 13 can effectively prevent the wheel body 10 from being deformed under pressure, and the buffer ring 12 can play the role of cushioning and silence, and its doors and windows can In the case of long-term use and without sliding for a long time, the wheel body 10 can still slide smoothly, without a sense of blockage or abnormal noise, and the use experience is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com