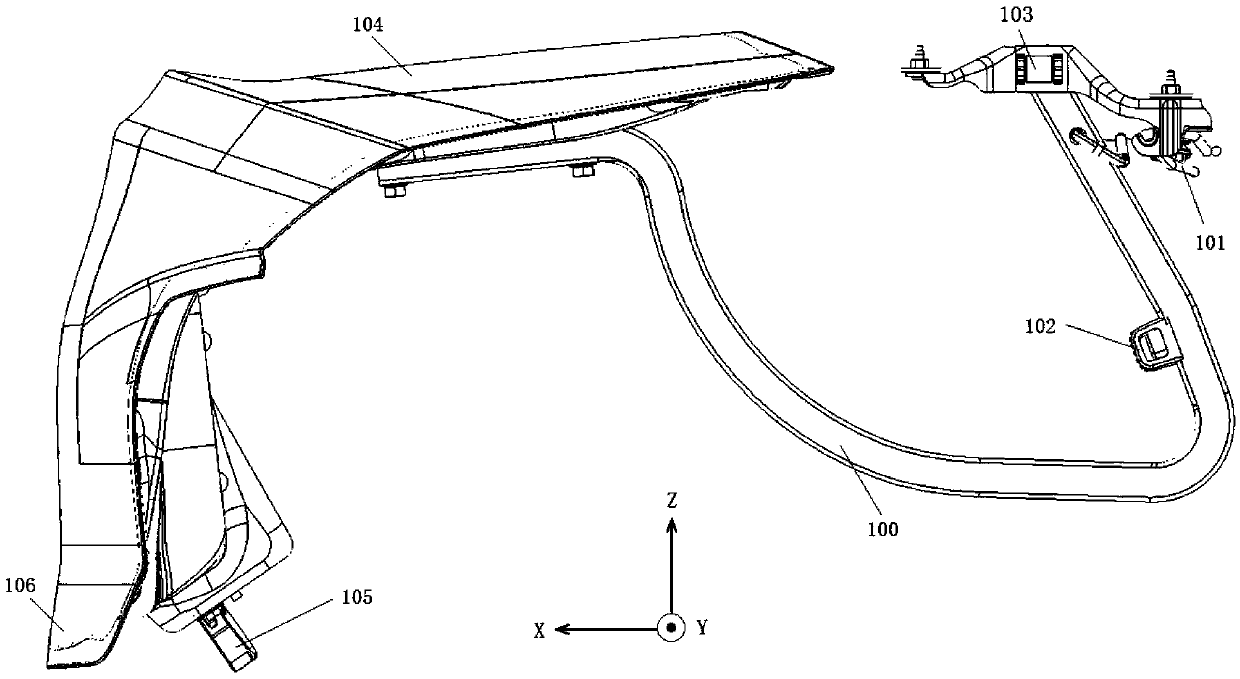

Verification device for automobile trunk assembly operation performance

A technology of operation performance and verification device, which is applied in the direction of measurement device, vehicle test, mechanical component test, etc., can solve the problems of inaccuracy, difficulty, unsatisfactory maneuverability evaluation effect, etc., and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

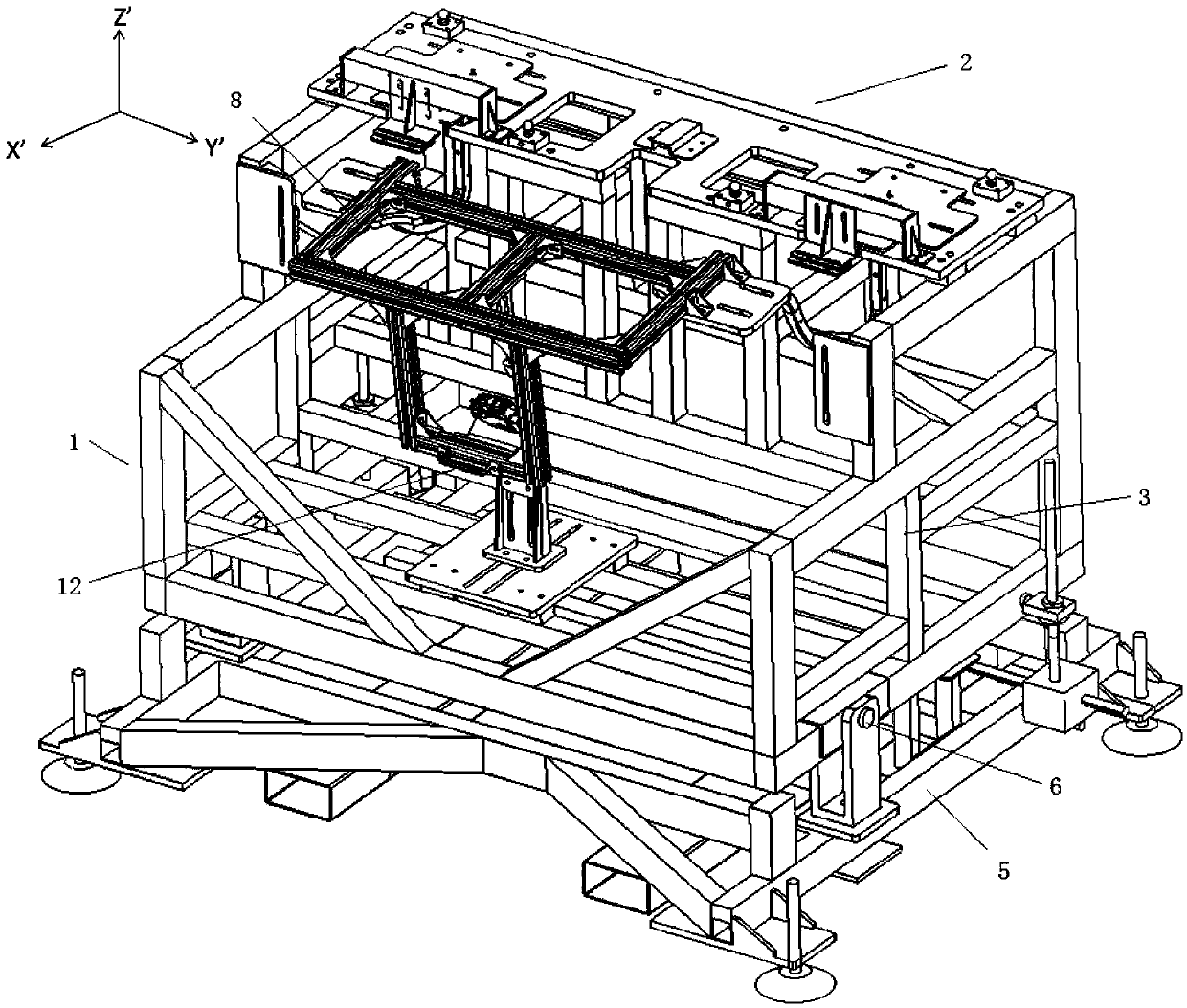

[0044] The invention relates to a verification device for the operation performance of the automobile trunk assembly, such as figure 2 As shown, the device includes a base part 1 and an operating part 2 , and the operating part 2 is arranged on the base part 1 .

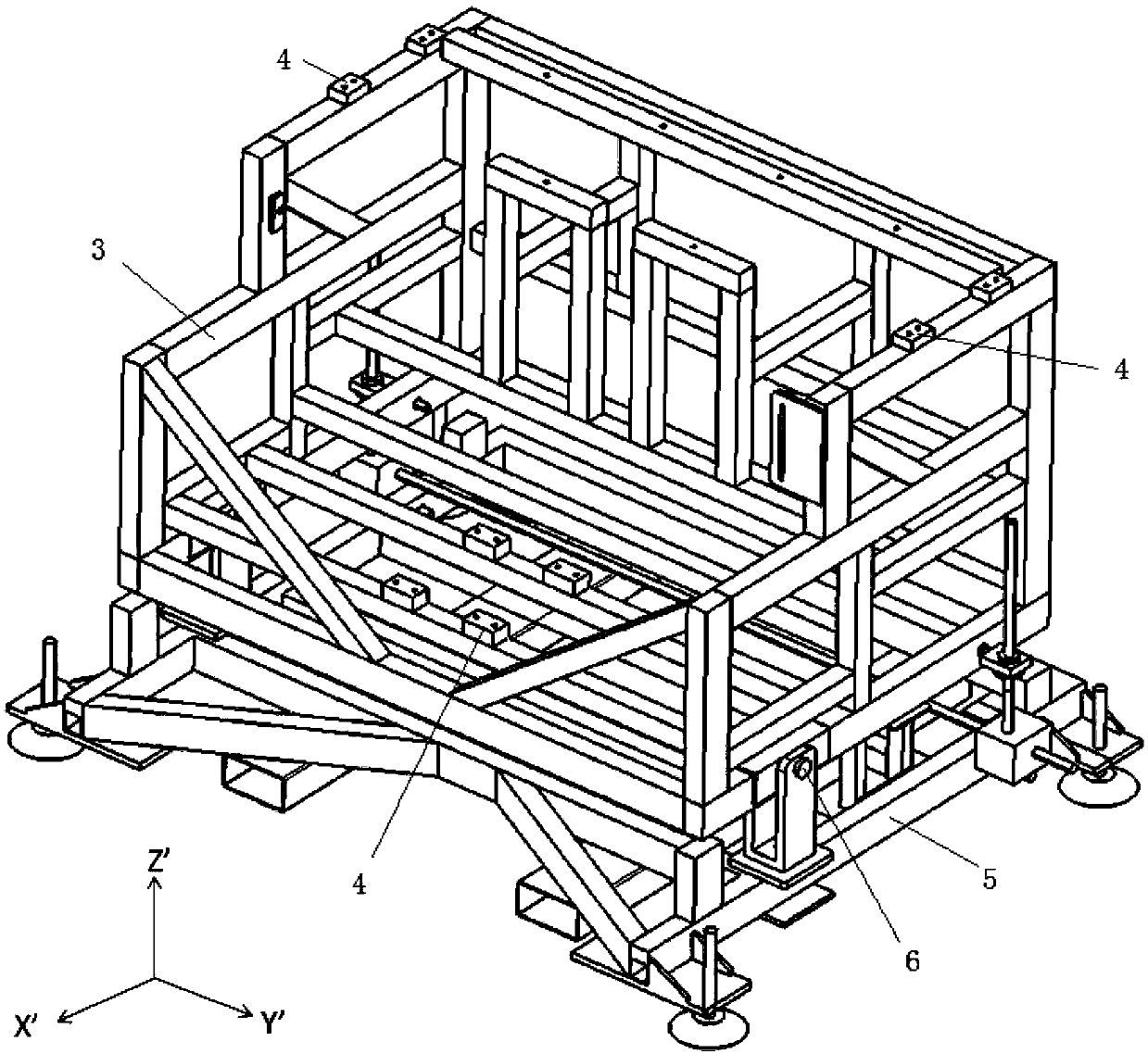

[0045] like Figure 3 ~ Figure 5 As shown, the base part 1 is composed of a trunk-type combined frame 3 , a bolt and nut connecting plate 4 , a combined frame base 5 , a rotating shaft 6 and a screw rod 10 . The height of the front end of the trunk type combined frame 3 is lower than that of the rear end. The bolt and nut connecting plate 4 is arranged on the front end and the side wall of the trunk type combined frame 3, and the bolt and nut connecting plate 4 is provided with screw holes for fixing the operation part 2 through the bolt and nut connecting structure. The front end of trunk type combination frame 3 is fixed on the combination frame base 5 by rotating shaft 6, and an end of screw rod 10 is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com