Method for forming bonding structure between wafers and wafer bonding method

A bonding structure and wafer technology, applied in the formation of inter-wafer bonding structure, wafer bonding field, can solve the problems such as difficult to guarantee the bonding strength, achieve high bonding strength, improve the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

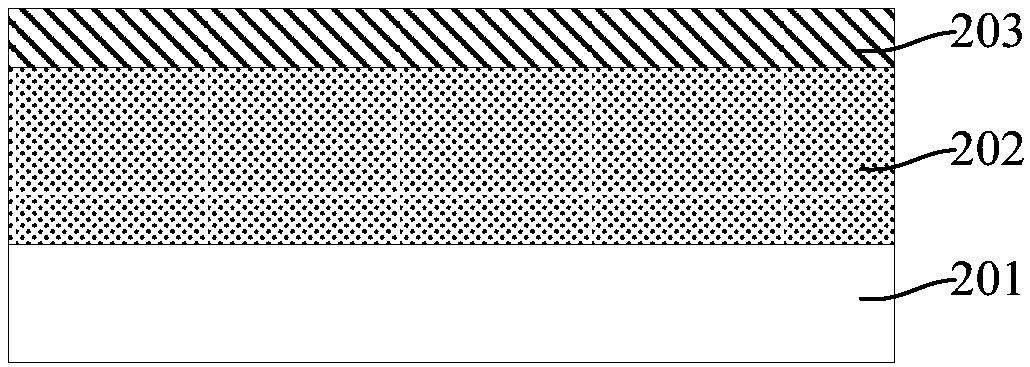

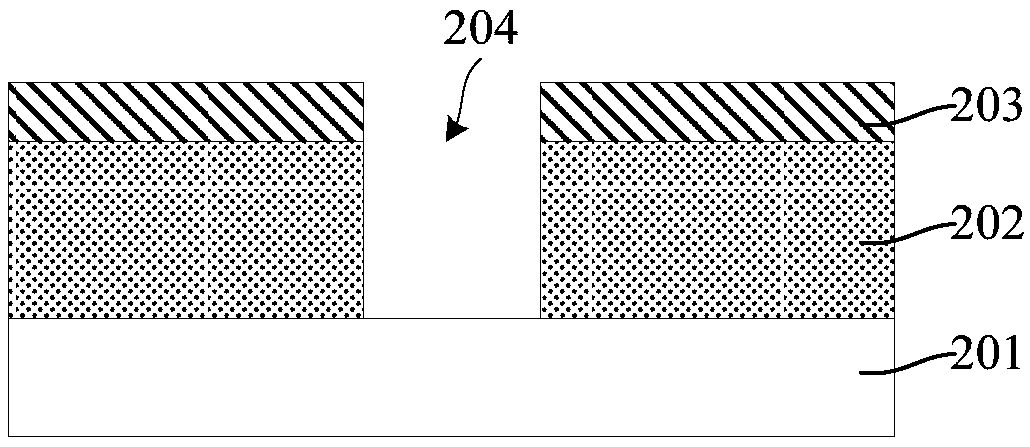

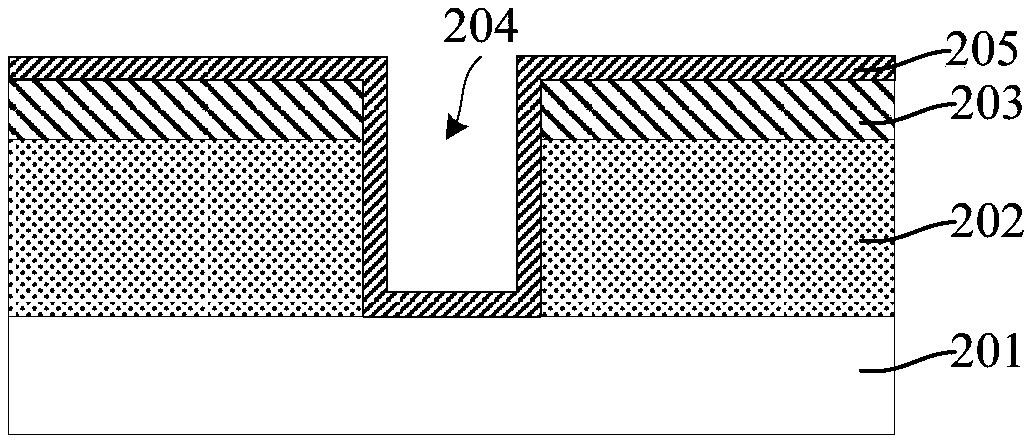

[0028] As mentioned in the background art, copper dishing defects are likely to occur on the surface of the bonding metal layer, and it is difficult to guarantee the bonding strength when wafers are bonded.

[0029] Research has found that when forming an insulating layer and a bonding metal layer in the insulating layer, the material of the insulating layer is usually silicon nitride, and the material of the metal layer is copper. The process of forming the bonding metal layer includes: A through hole (or groove) is formed in the layer; an electroplating process is used to form a metal layer covering the insulating layer, and the metal layer fills the through hole (or groove); a chemical mechanical polishing process is used to planarize the metal layer to The surface of the insulating layer acts as a stop layer, forming a bonding metal layer in the via hole (or trench). During the chemical mechanical polishing process, due to the low grinding rate of the insulating layer of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com