Ingaas detector chip and preparation method thereof

A detector chip and absorbing layer technology, which is applied in the field of InGaAs detector chip and its preparation, can solve the problems of reduced chip life, chip failure, and normal use of customers, so as to increase junction capacitance, improve antistatic ability, and ensure reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

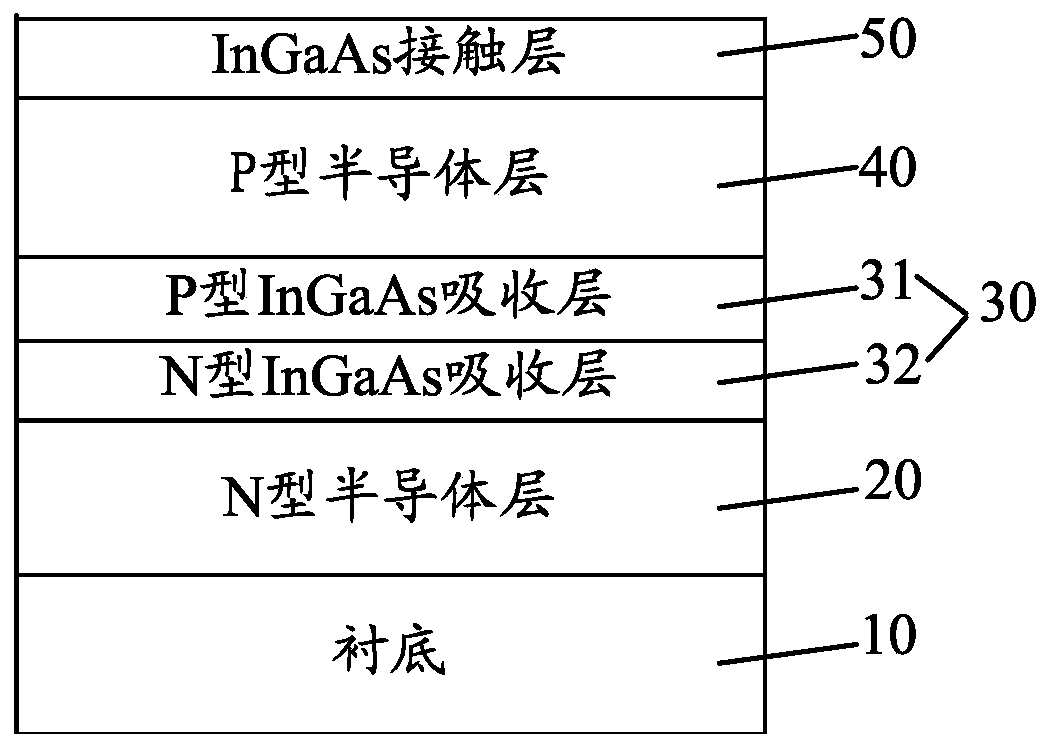

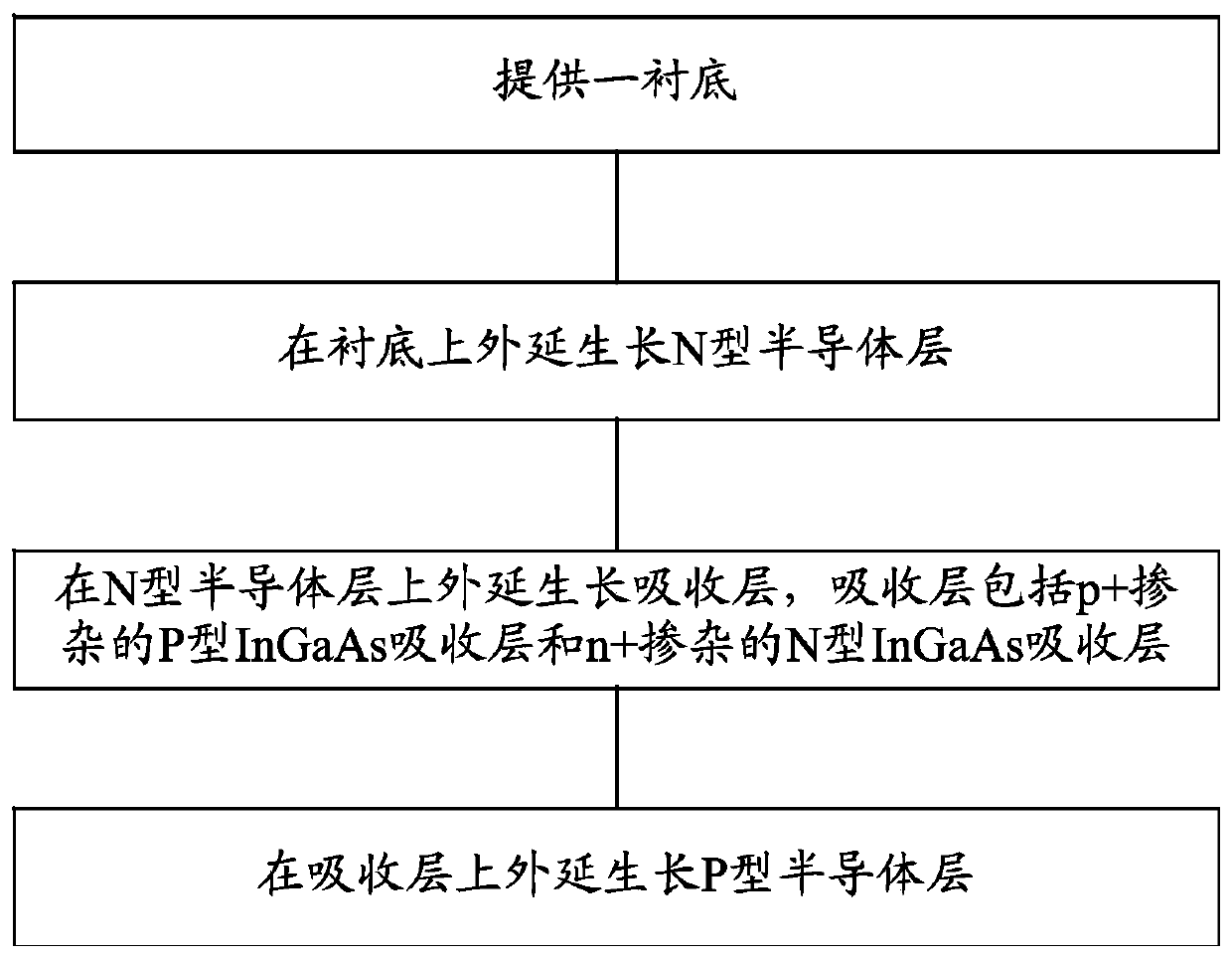

[0030] ginseng figure 2 As shown, the present invention also discloses a method for preparing an InGaAs detector chip, comprising:

[0031] providing a substrate;

[0032] epitaxially growing an N-type semiconductor layer on the substrate, the N-type semiconductor layer being an n+ doped InP layer;

[0033] The absorber layer is epitaxially grown on the N-type semiconductor layer. The absorber layer includes a p+ doped P-type InGaAs absorber layer and an n+ doped N-type InGaAs absorber layer. The P-type InGaAs absorber layer is located above the N-type InGaAs absorber layer, and the P-type InGaAs The thickness of the absorbing layer is smaller than the thickness of the N-type InGaAs absorbing layer, and the doping concentration of the P-type InGaAs absorbing layer is greater than that of the N-type InGaAs absorbing layer;

[0034] A P-type semiconductor layer is epitaxially grown on the absorption layer, and the P-type semiconductor layer is a p+ doped InP layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com