Ultraviolet photodiode based on CuAlO2/SiC and preparation method thereof

An ultraviolet light and diode technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problem of low P-type silicon carbide doping concentration, and achieve high critical breakdown electric field strength, excellent detection performance, and improved reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

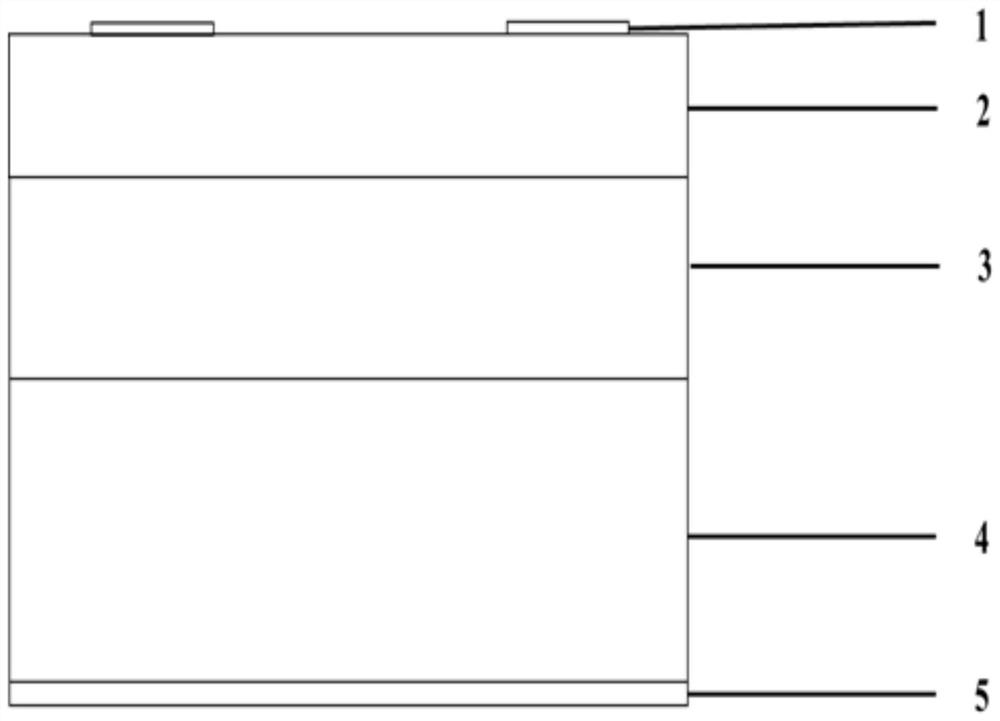

[0063] A kind of CuAlO of the present invention 2 / SiC UV photodiodes, structured as figure 1 As shown, the top electrode 1 and the bottom electrode 5 are included, and the P-type crystal CuAlO is arranged in sequence from the top electrode 1 to the bottom electrode 5 between the two electrodes. 2 Thin film 2, I-type SiC thin film 3 and N-type SiC substrate 4.

[0064] The material of the top electrode 1 and the bottom electrode 5 is a mixture of any of the metal materials of Au, Al, Ni, Cu, and Pb, or an alloy containing one or any of the above-mentioned mixed metal materials, or the conductivity of ITO compound.

[0065] The N-type SiC substrate 4 is a nitrogen-doped SiC material; the I-type crystalline SiC thin film is an unintentionally doped SiC layer, and the doping concentration is 10 15 cm ~3 .

[0066] P-type crystal CuAlO 2 The doping concentration of film 2 is 10 17 cm ~3 .

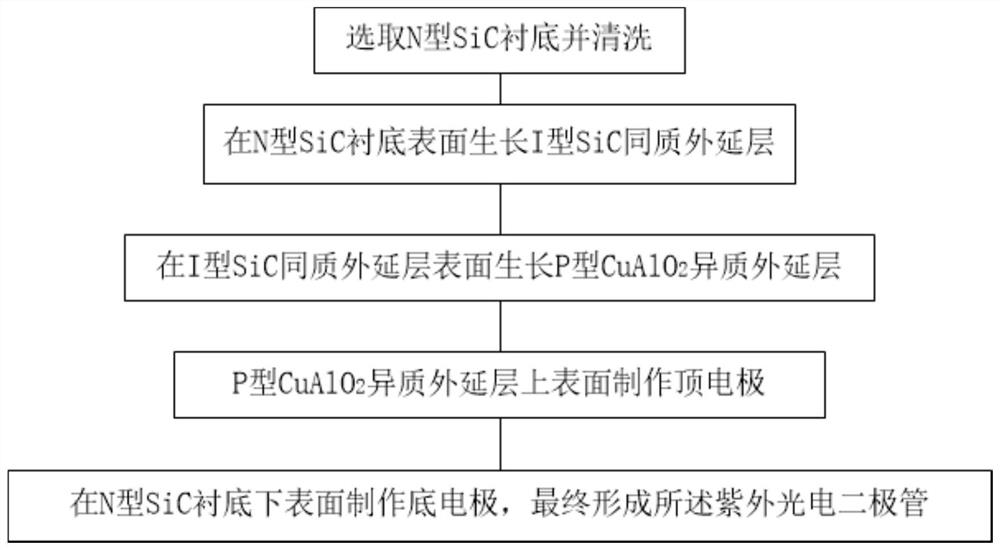

[0067] a CuAlO 2 / SiC ultraviolet photodiode preparation method, the flow chart i...

Embodiment 2

[0088] A kind of CuAlO of the present invention 2 / SiC UV photodiodes, structured as figure 1 As shown, the top electrode 1 and the bottom electrode 5 are included, and the P-type crystal CuAlO is arranged in sequence from the top electrode 1 to the bottom electrode 5 between the two electrodes. 2 Thin film 2, I-type SiC thin film 3 and N-type SiC substrate 4.

[0089] The material of the top electrode 1 and the bottom electrode 5 is Au.

[0090] The N-type SiC substrate 4 is a nitrogen-doped SiC material; the I-type crystalline SiC thin film is an unintentionally doped SiC layer, and the doping concentration is 10 15 cm ~3 .

[0091] P-type crystal CuAlO 2 The doping concentration of film 2 is 10 18 cm ~3 .

[0092] a CuAlO 2 / SiC ultraviolet photodiode preparation method, the flow chart is as figure 2 As shown, the specific steps are as follows:

[0093] Step 1, cleaning the N-type SiC substrate 4, and drying it for later use;

[0094] Step 2, growing an intrins...

Embodiment 3

[0113] A kind of CuAlO of the present invention 2 / SiC UV photodiodes, structured as figure 1 As shown, the top electrode 1 and the bottom electrode 5 are included, and the P-type crystal CuAlO is arranged in sequence from the top electrode 1 to the bottom electrode 5 between the two electrodes. 2 Thin film 2, I-type SiC thin film 3 and N-type SiC substrate 4.

[0114] The material of the top electrode 1 and the bottom electrode 5 is a mixture of Ni, Cu, and Pb metal materials.

[0115] The N-type SiC substrate 4 is a nitrogen-doped SiC material; the I-type crystalline SiC thin film is an unintentionally doped SiC layer, and the doping concentration is 10 15 cm ~3 .

[0116] P-type crystal CuAlO 2 The doping concentration of film 2 is 10 18 cm ~3 .

[0117] a CuAlO 2 / SiC ultraviolet photodiode preparation method, the flow chart is as figure 2 As shown, the specific steps are as follows:

[0118] Step 1, cleaning the N-type SiC substrate 4, and drying it for later ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com