High-quality and efficient submarine cable laying system and method

A submarine cable and high-efficiency technology, applied in the field of high-quality and efficient submarine cable laying system, can solve the problems of manpower and material resources, long construction period, etc., and achieve the effect of stable transmission ratio, good equipment safety and reliability, and wide speed regulation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

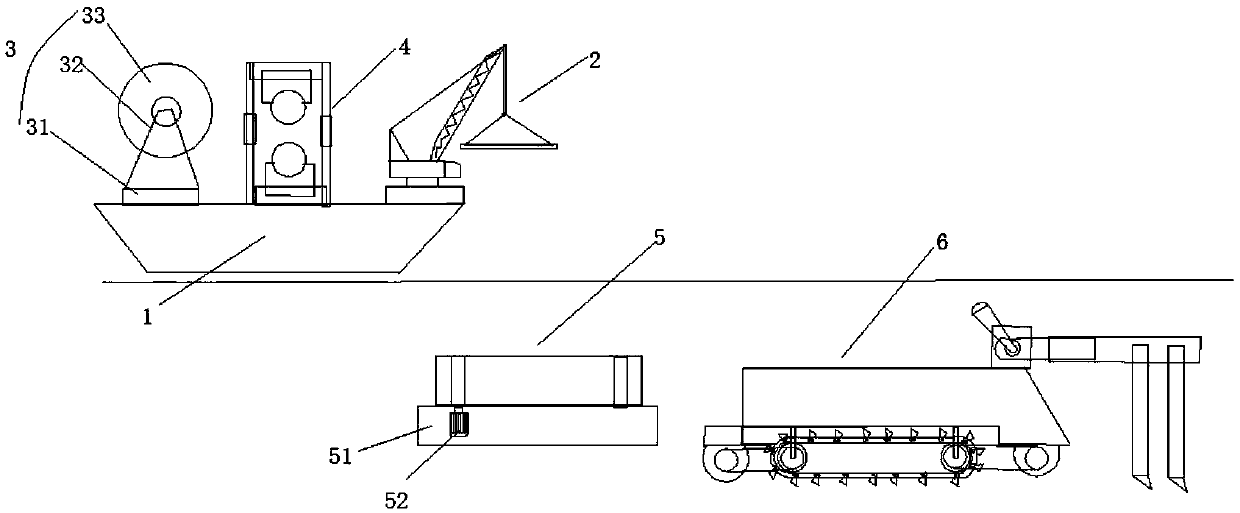

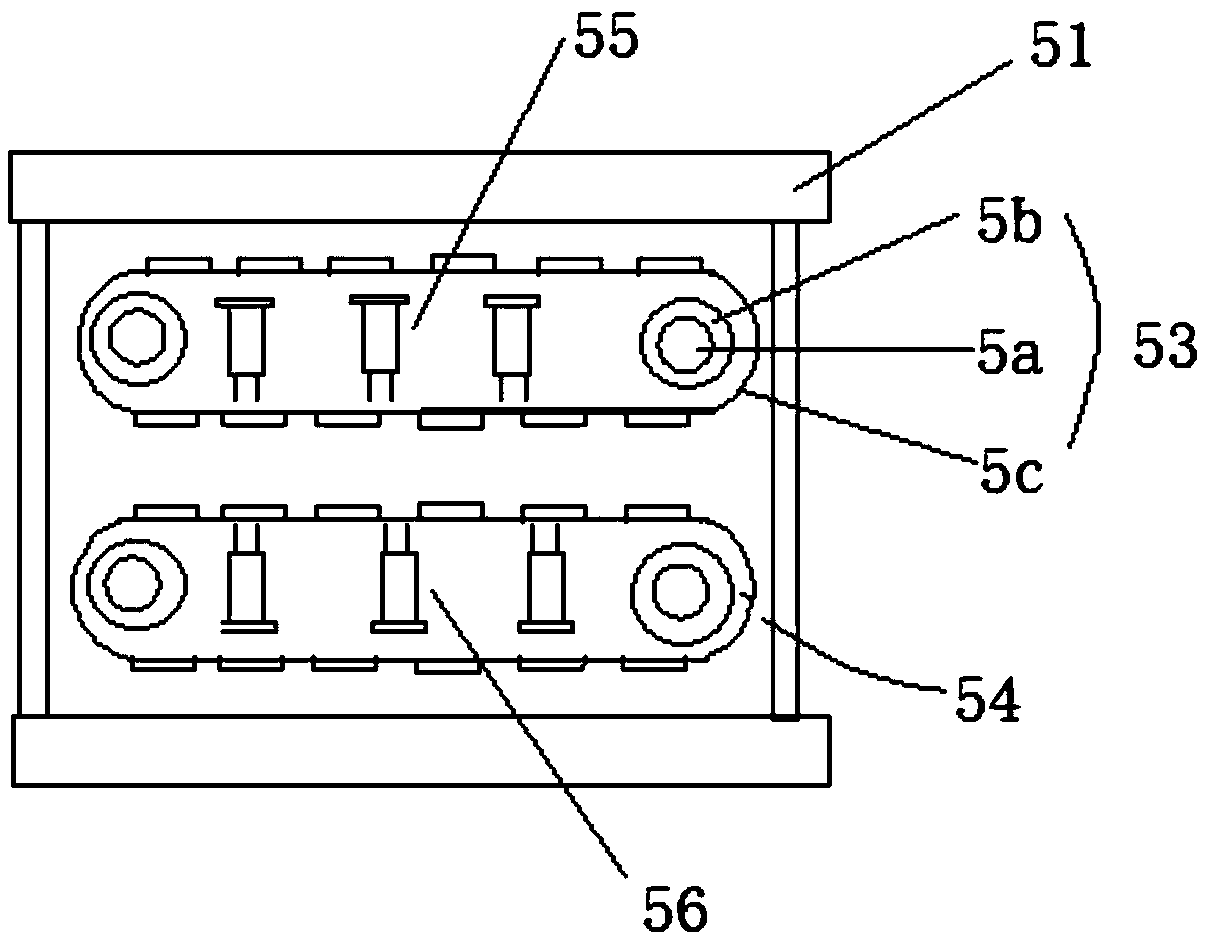

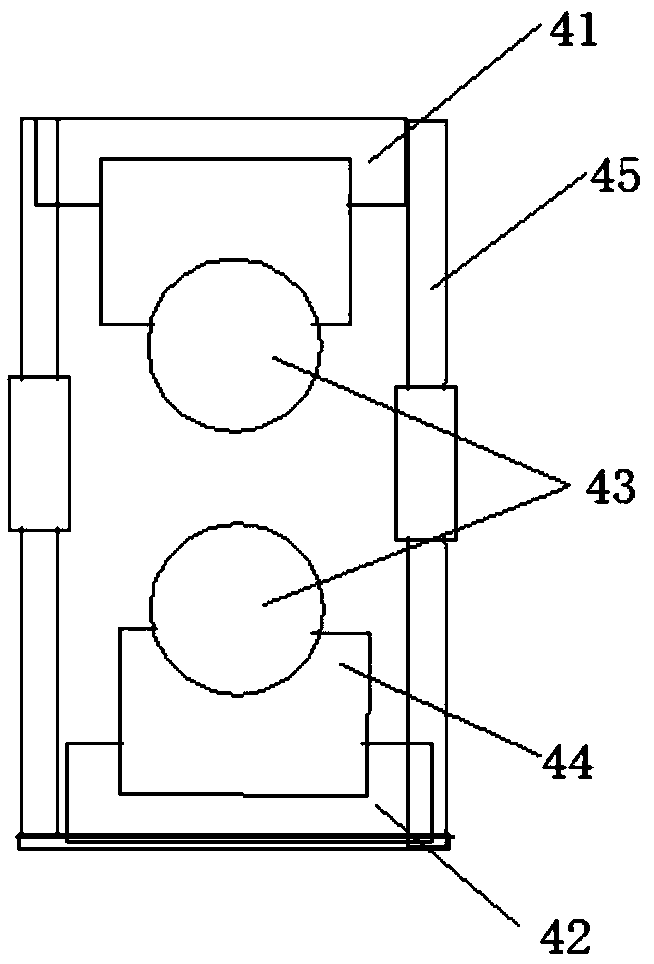

[0022] like Figure 1-5 A high-quality and high-efficiency submarine cable laying system is shown, including a construction vessel 1, a door crane 2, a cable untwisting disc 3, a fairlead device 4, a cable laying machine 5 and a submarine cable burying machine 6, the door crane 2, The submarine cable twisting disc 3 and the fairlead device 4 are both arranged on the construction vessel 1 , the submarine cable twisting disc 3 is arranged on the left side of the fairlead device 4 , and the cable laying machine 5 is arranged on the right side of the fairlead device 4 , The door hanger 2 is arranged on the right side of the cable laying machine 5 , and the submarine cable burying machine 6 is placed into the seabed through the door hanger 2 .

[0023] The submarine cable untwisting disc 3 includes a base 31, a fixing bracket 32 and a submarine cable disc 33. The fixing bracket 32 is arranged above the base 31, and the fixing bracket 32 is provided with a submarine cable disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com